Equipment for detecting fault of Toshiba 2.5-inch hard disk and fault detection method of equipment

A technology for detecting equipment and hard disk failures, applied in error detection/correction, instrumentation, electrical digital data processing, etc. The effect of high detection accuracy and improved wiring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

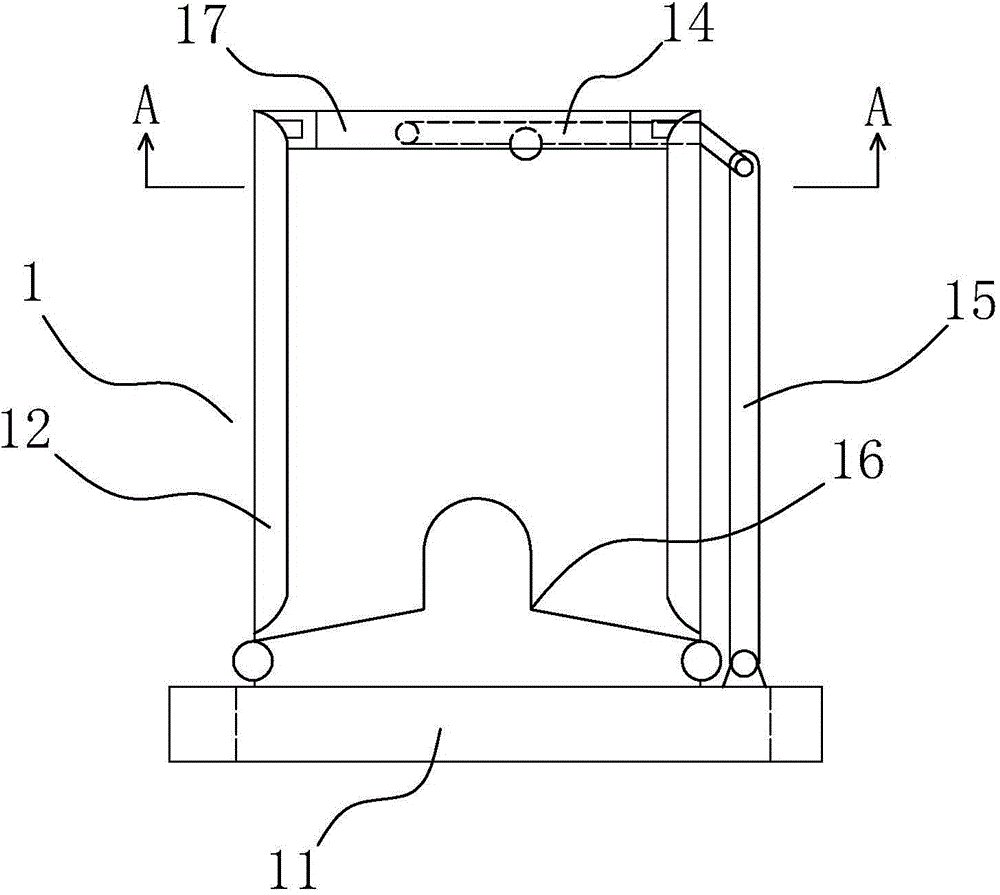

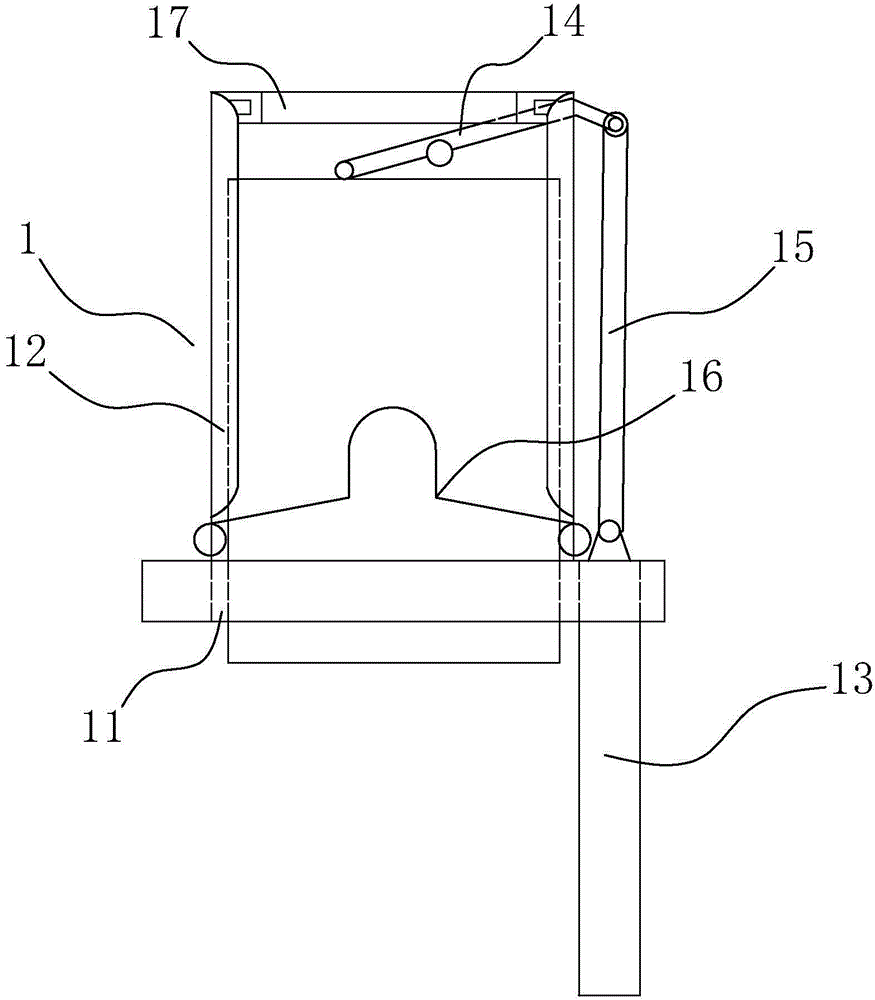

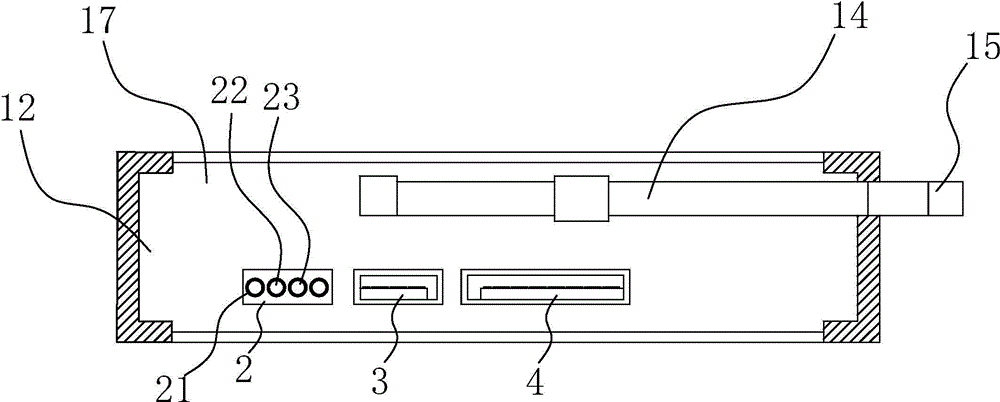

[0032] refer to figure 1 - Figure 6 , a Toshiba 2.5-inch hard disk failure detection device of the present invention, comprising a hard disk mounting bracket 1 and a TTL main chip circuit board 5, the hard disk mounting bracket 1 includes a hard disk inlet 11 and is arranged on both sides thereof for pushing the Toshiba hard disk To the flat push-type guide groove 12 at the bottom of the rear side, the hard disk mounting bracket 1 includes a wiring panel 17 arranged on the rear side, and the wiring panel 17 is provided with a COM connection port 2 corresponding to the COM port position of the Toshiba hard disk, The COM connection port 2 is provided with 4 sockets 21 corresponding to 4 pins in the COM port of the Toshiba hard disk respectively, and the TTL main chip circuit board 5 includes a TTL main chip 51 and a USB for connecting the PC controller 6. Port 52, the output ends of the 4 sockets 21 in the COM connection port 2 are connected to the TTL main chip 51, and the PC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com