Method and device for shaping a workpiece

A workpiece and reshaping technology, applied in the direction of metal processing equipment, etc., can solve problems such as wall thickness and hub design restrictions, achieve effective hardening and forming, improve reliability, and reduce stretching or deep drawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

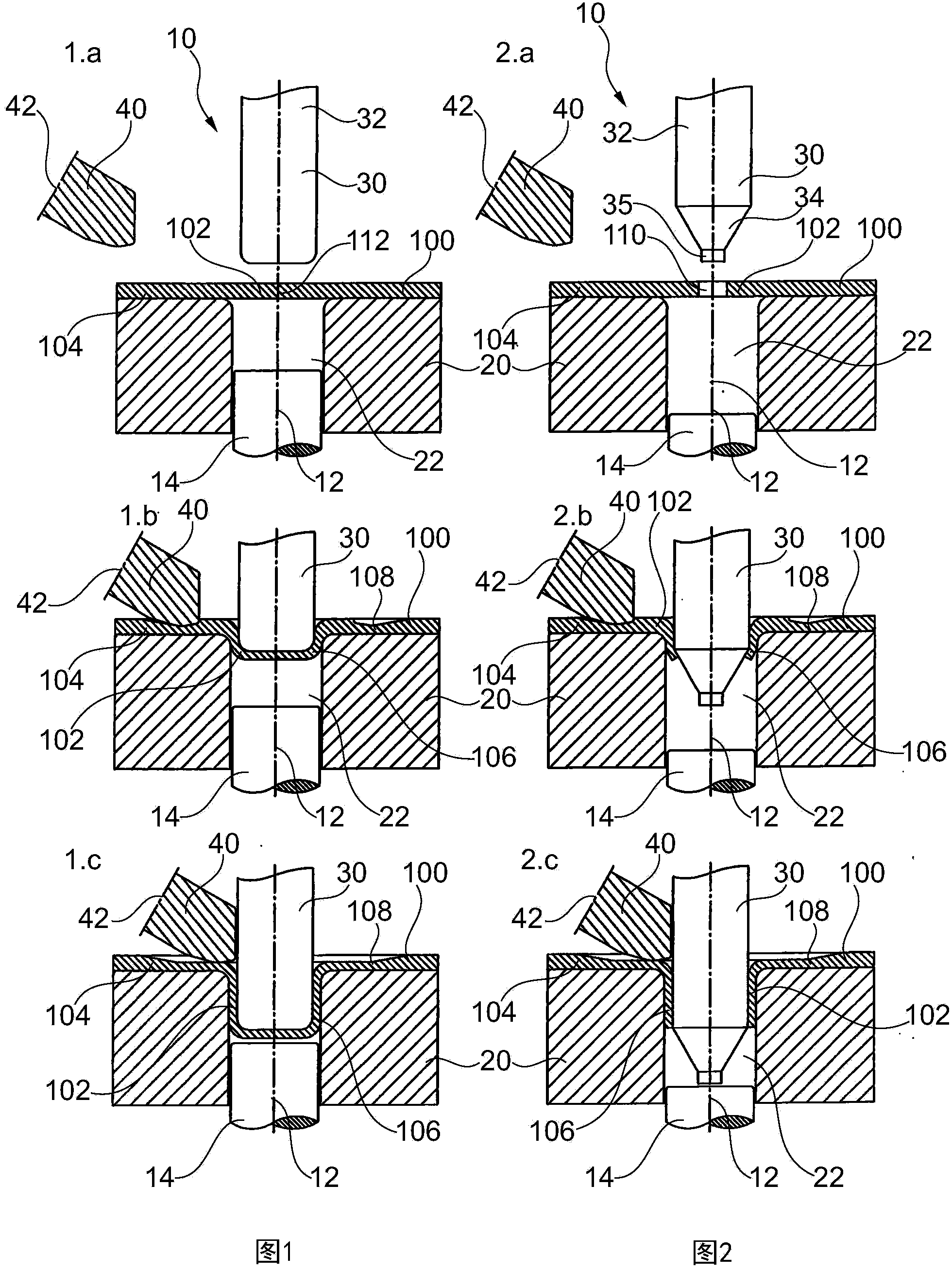

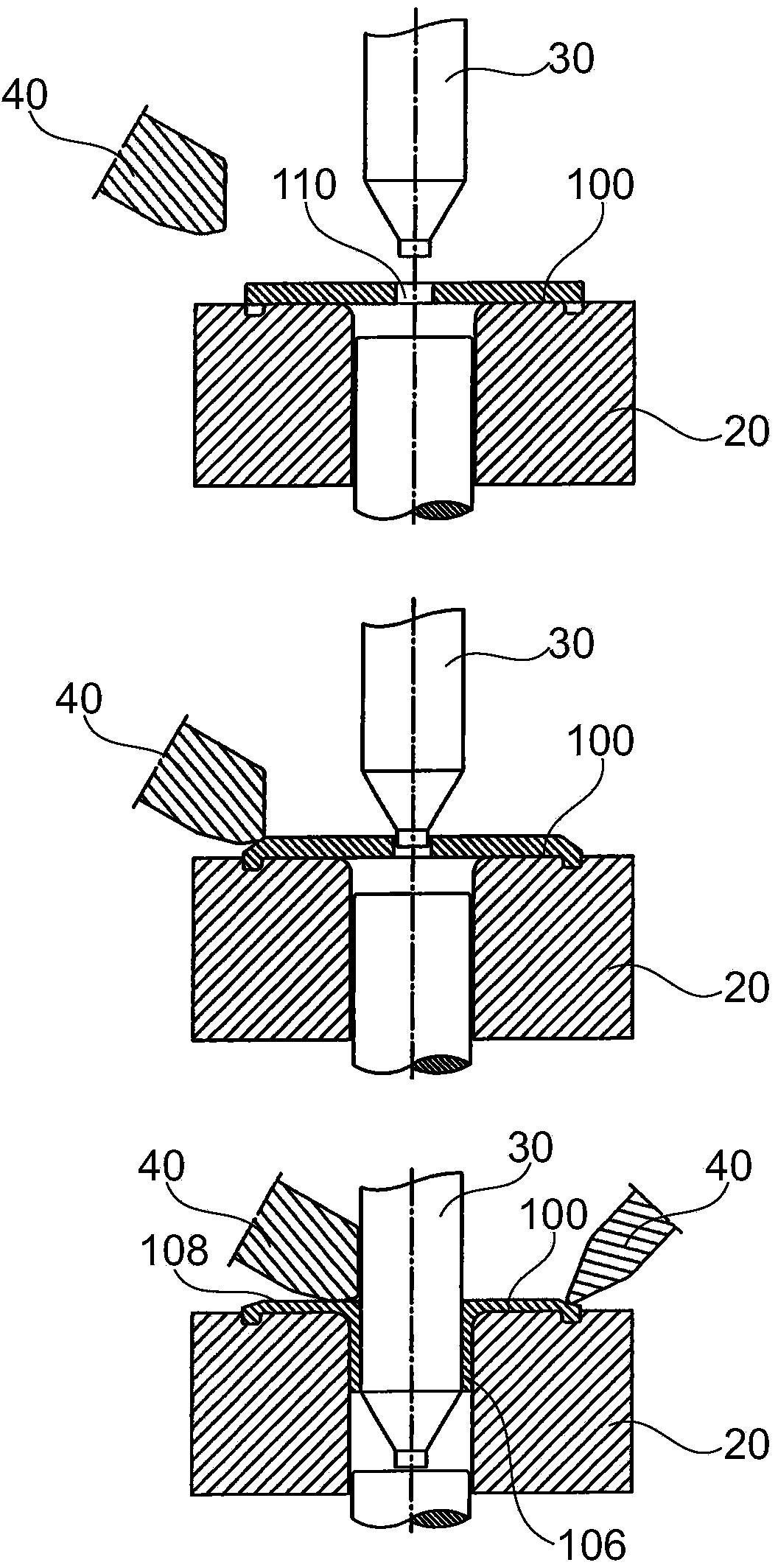

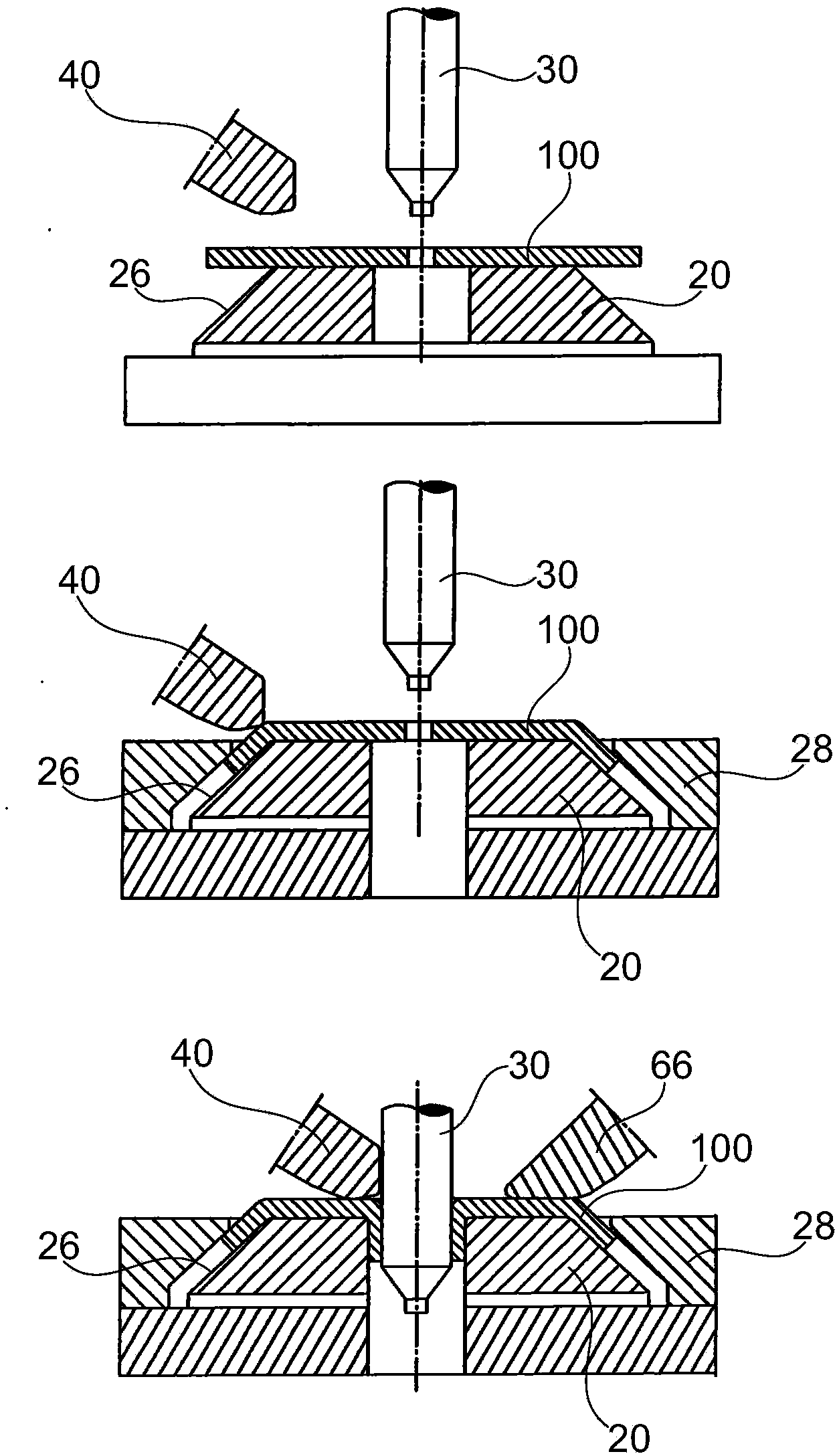

[0082] figure 1 and figure 2 The basic aspects of the method of the invention and the apparatus 10 of the invention are shown, shown non-cuttingly forming a drum or hub from a preferably substantially rotationally symmetrical workpiece 100, such as a circular sheet metal blank or preformed blank. example of .

[0083] The device 10 for reshaping a workpiece 100 comprises a die 20 having a substantially central entry hole 22 into which a punch 30 can be moved linearly in the axial direction. The die 20 and the punch 30 are adjusted to each other such that a stretching gap is formed therebetween into which the inner region 102 of the workpiece 100 is stretched when the punch 30 is driven into the die 20 .

[0084] Die 20 and punch 30 are mounted and can be driven for rotation about axis of rotation 12 on a machine tool (not shown). The workpiece 100 can be positioned on the mold 20 and the workpiece 100 can also be rotated about the mold 20 . Work piece 100 may also be cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com