A production process of aluminum foil for power battery

A power battery and production process technology, which is applied in the production process field of aluminum foil for power batteries, can solve the problems of difficult control of front and rear tension, easy occurrence of burrs and ruffles, etc., and achieve the effects of easy operation, product quality improvement and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

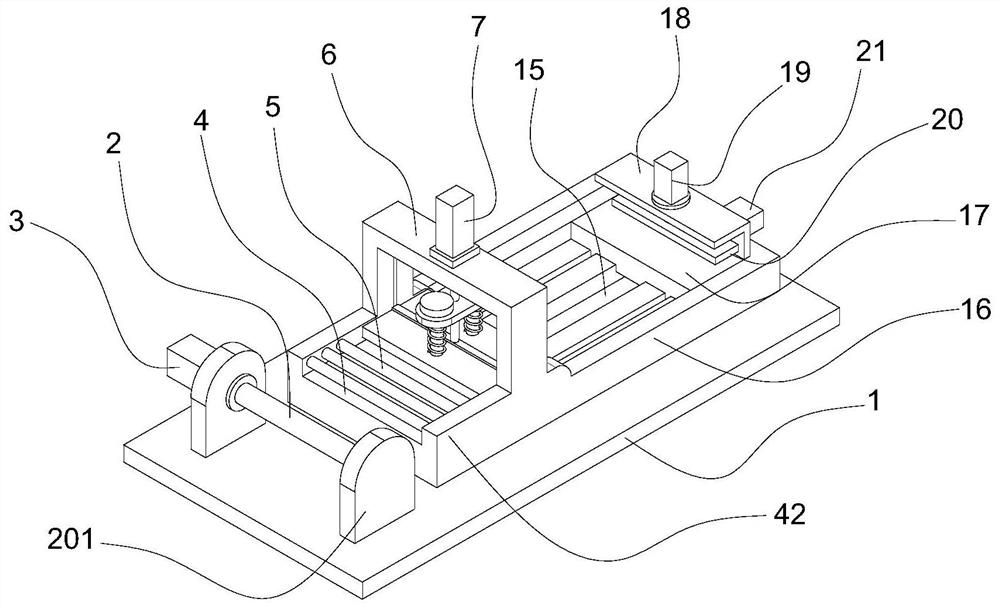

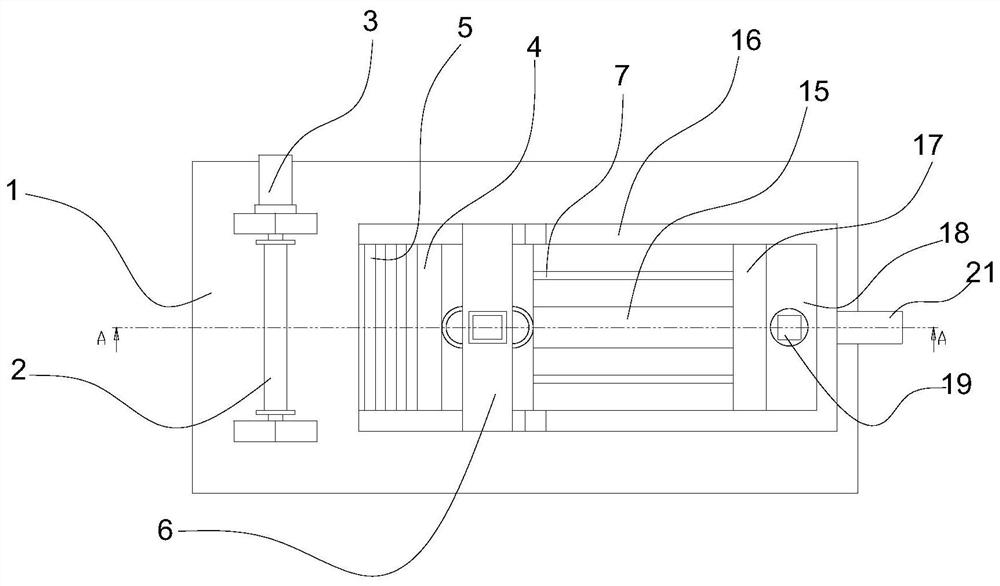

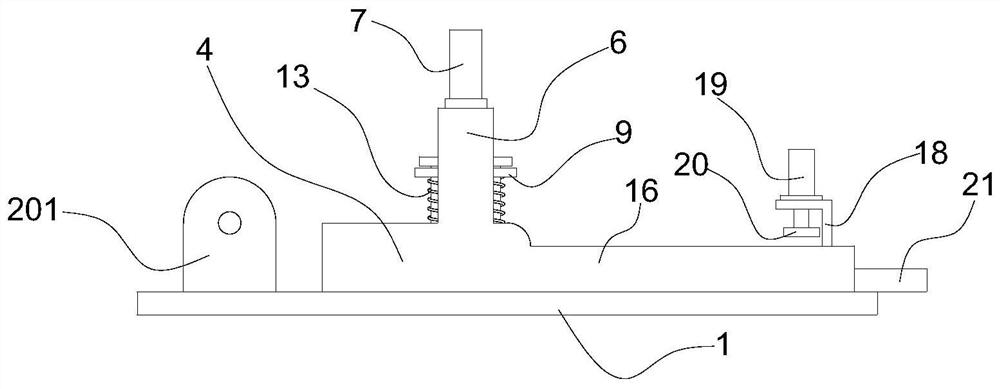

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0049] Such as Figure 1 to Figure 4 As shown, the production process of the aluminum foil for power battery according to the present invention, the aluminum foil for power battery includes: Si, Fe, Cu, Mn, Mg, Zn, Ti, AL; the content of Cu is 0.17%-0.20%, Si content is less than 0.07%;

[0050] and include the following steps:

[0051] 1) Weighing and mixing each raw material by weight percentage, first smelting to obtain a melt, and then casting and rolling the melt to form a casting billet;

[0052] 2) Carry out homogenization annealing to the cast-rolled billet formed by casting and rolling; the aluminum alloy strip is subjected to homogenization annealing at 580° C. for 4.5 hours and 550° C. for 20 hours, and the aluminum alloy strip during homogenization annealing The thickness is 3.5mm;

[0053] 3) cold-rolling the above-mentioned cast-rolled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com