Tensioning oil cylinder inner hole surface strengthening tool and strengthening method

A surface strengthening and oil cylinder technology, which is applied in the field of oil cylinder manufacturing, can solve problems such as inaccurate preload force, lateral deformation of the oil cylinder, and deterioration of rolling conditions, and achieve high control accuracy, reduce lateral deformation, and improve adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

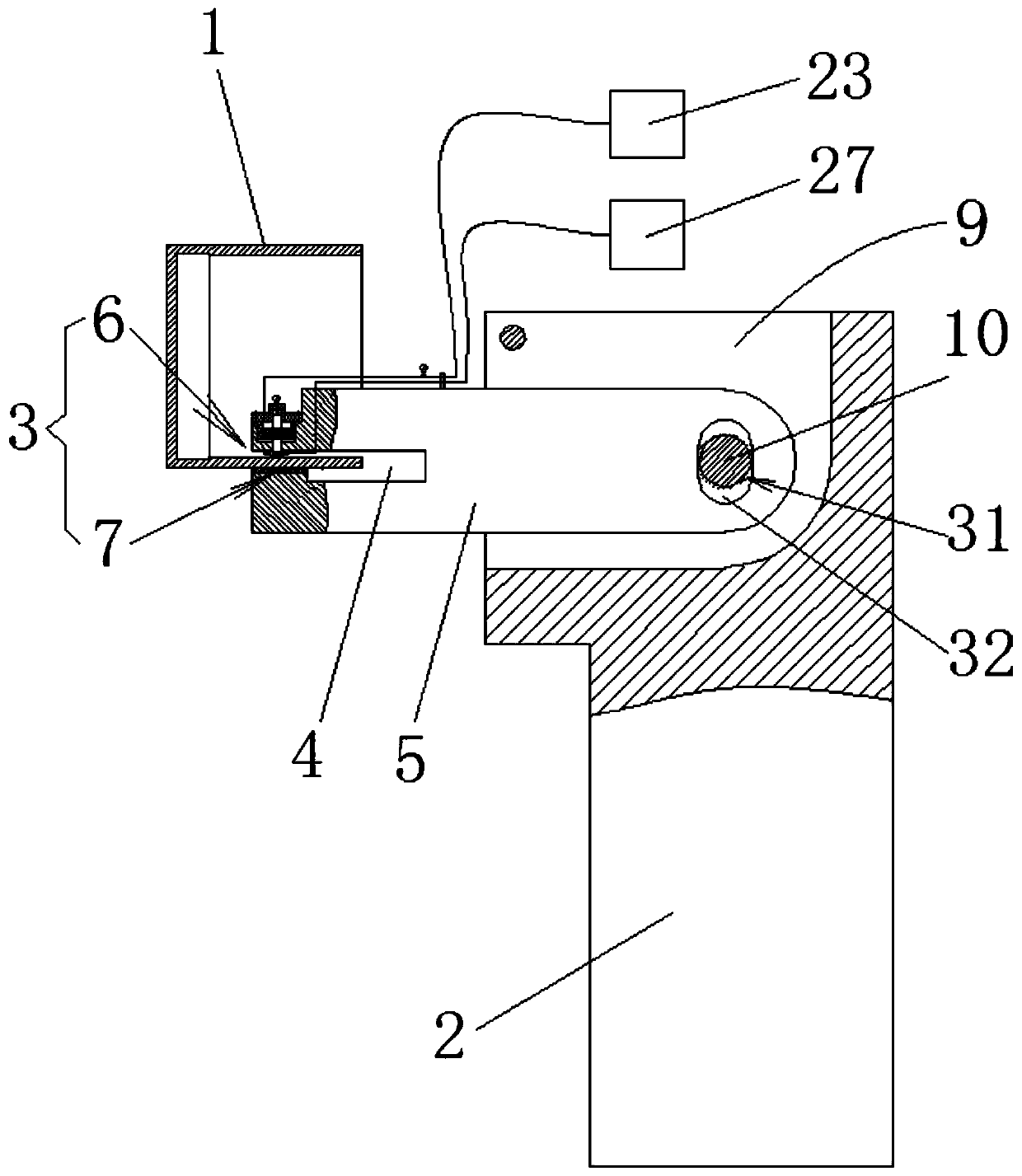

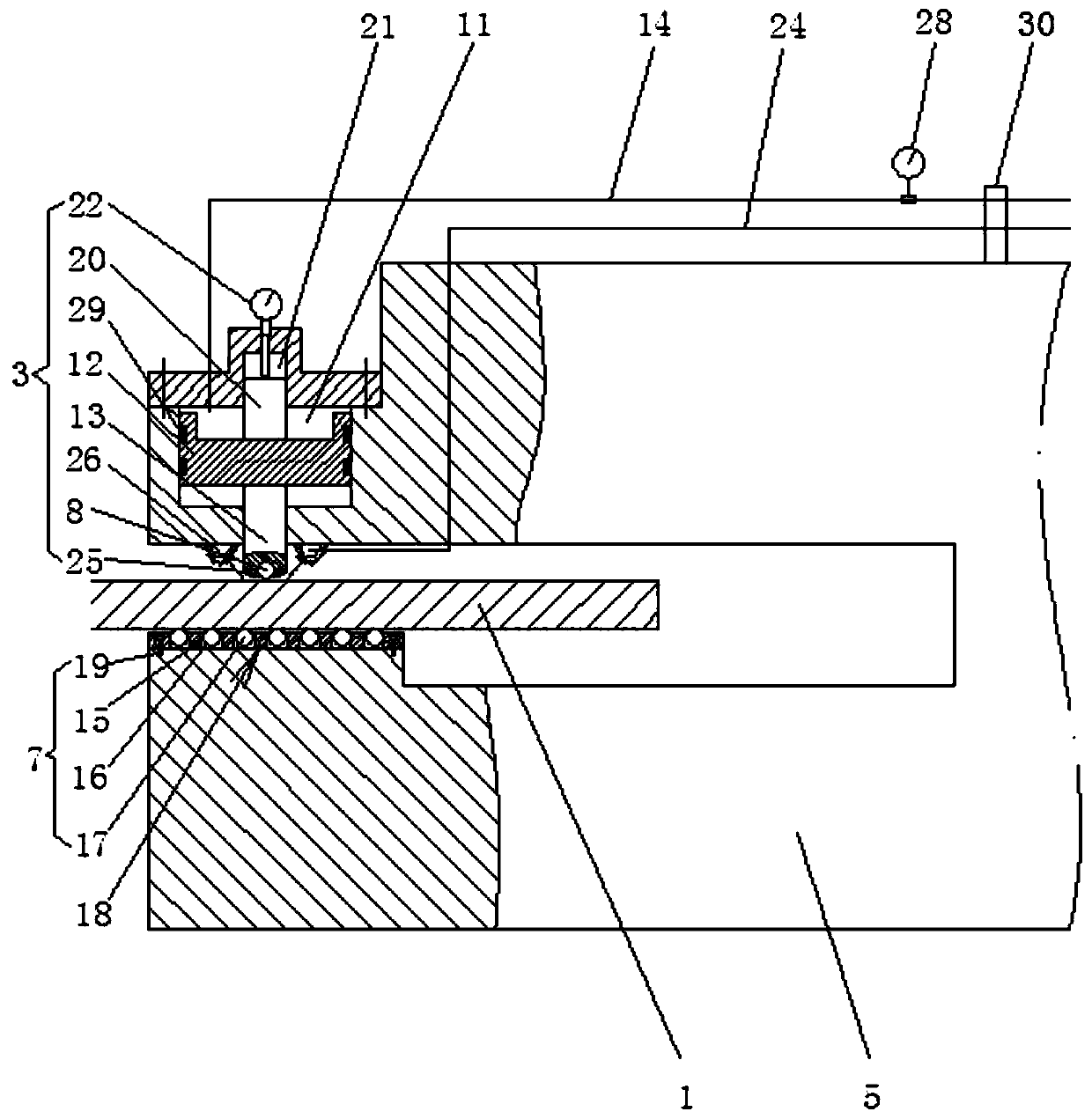

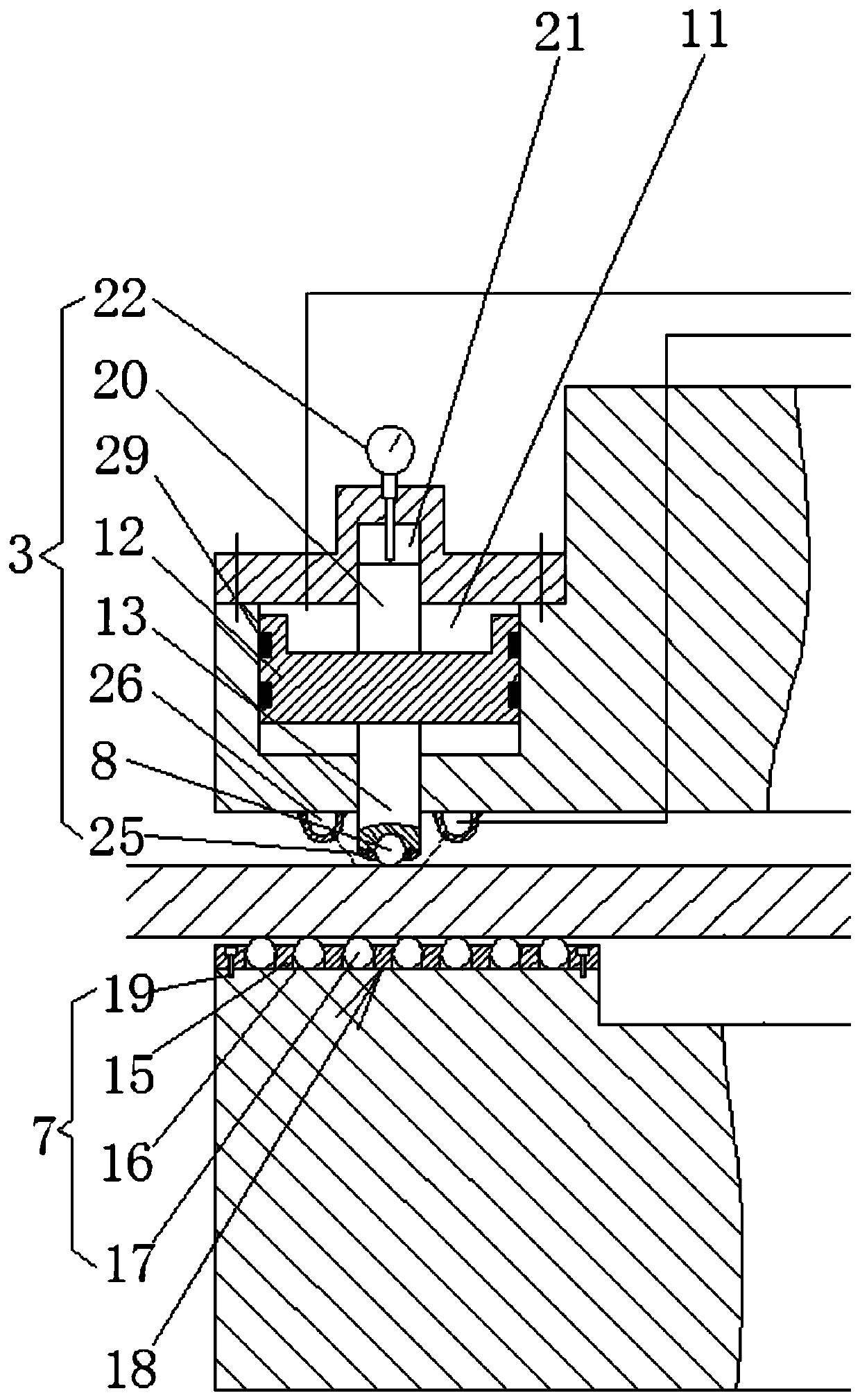

[0045] Such as Figures 1 to 3 Shown is an embodiment of a tensioning cylinder inner hole surface strengthening tool of the present invention, including a clamping handle 2 and a floating rolling module 3 movably connected to the clamping handle 2, and the floating rolling module 3 It includes a rigid seat block 5 with an opening groove 4, a rolling assembly 6 arranged on the side of the groove 4 of the rigid seat block 5 for rolling and strengthening the inner hole surface of the tensioning cylinder 1, arranged on The other side of the groove 4 of the rigid block 5 is used to support the outer circle of the tensioning cylinder 1 to balance the rolling force of the linear moving ball assembly 7, and the rolling head of the rolling assembly 6 faces the linear moving ball assembly 7. During rolling, the rolling head 8 of the rolling assembly 6 presses against the inner hole surface of the tensioning cylinder 1, and the ball 17 on the linear moving ball assembly 7 sticks to the o...

Embodiment 2

[0062] A strengthening method using the high-strength tension cylinder inner hole surface strengthening tool of embodiment 1, comprising the following steps:

[0063] (1) Clamp the tensioning cylinder 1 on the rotating spindle of the lathe, clamp the clamping handle 2 of the strengthening tool on the tool holder of the lathe, and move the carriage of the lathe so that the cylinder wall of the tensioning cylinder 1 enters the rigid seat of the strengthening tool In the opening groove 4 of the block 5;

[0064] (2) Open the pressure oil supply system 23, and set the pressure oil supply system 23 to a set initial pressure state, under the action of the initial pressure of the pressure oil, make the rolling head 8 withstand the inner hole of the tensioning cylinder 1 surface, and make the linear moving ball assembly 7 stick to the outer surface of the tensioning cylinder 1;

[0065] (3) adjust the dial indicator 22 on the strengthening tool to zero;

[0066] (4) The pressure oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com