Circular washing device for concrete stirring shaft

A technology for cleaning equipment and stirring shafts, which is applied in the field of cleaning equipment for concrete stirring shafts, and can solve problems such as waste of water resources, poor cleaning effect, and soil pollution, so as to avoid pollution, reduce water consumption, and improve cleaning effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

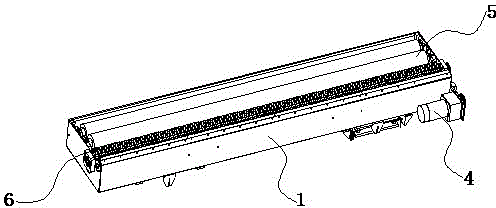

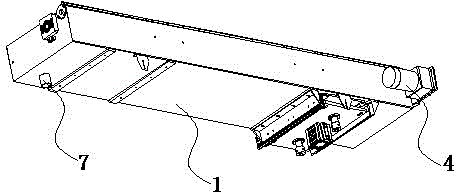

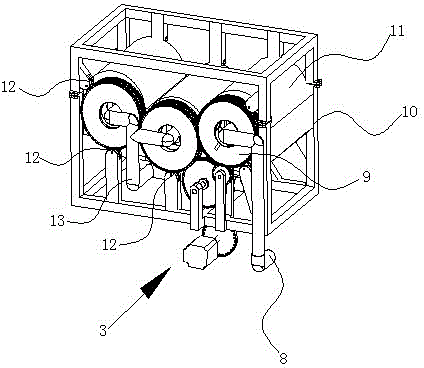

[0037] Such as Figure 1-10As shown, it is a cleaning device for a recyclable concrete mixing shaft of the present invention, including a separation device, a cleaning tank 1, a water spray pipe 6 rotatably installed in the cleaning tank 1, and a water spray pipe for driving The first motor 4 for the rotation of the tube 6, the stirring shaft 5 installed in the cleaning tank 1 in a rotatable manner and arranged side by side with the water spray pipe 6, the cleaning tank 1 is equipped with a cleaning tank 1 at a position corresponding to the stirring shaft 5 The device 2, the cleaning device 2 can be installed directly below the stirring shaft 5, a plurality of water spray holes are formed on the peripheral wall of the water spray pipe 6, and a first water outlet 7 is formed at the bottom of the cleaning tank 1;

[0038] Described separation device comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com