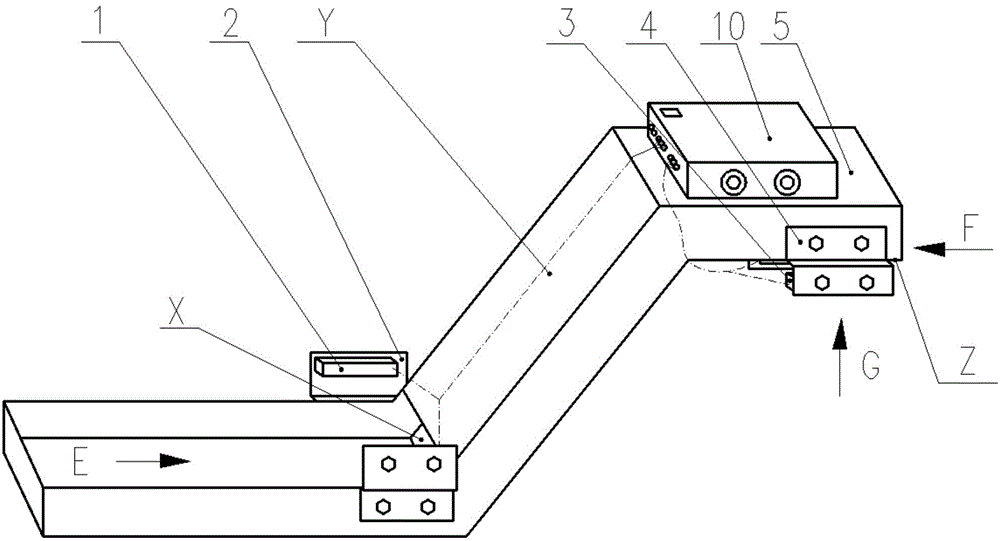

Chip plugging detection device for chain plate type chip remover

A detection device and chip conveyor technology, which is applied in the direction of measuring/indicating equipment, metal processing equipment, maintenance and safety accessories, etc., can solve problems such as unstable operation, prone to failure, negative impact on production work, etc., and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

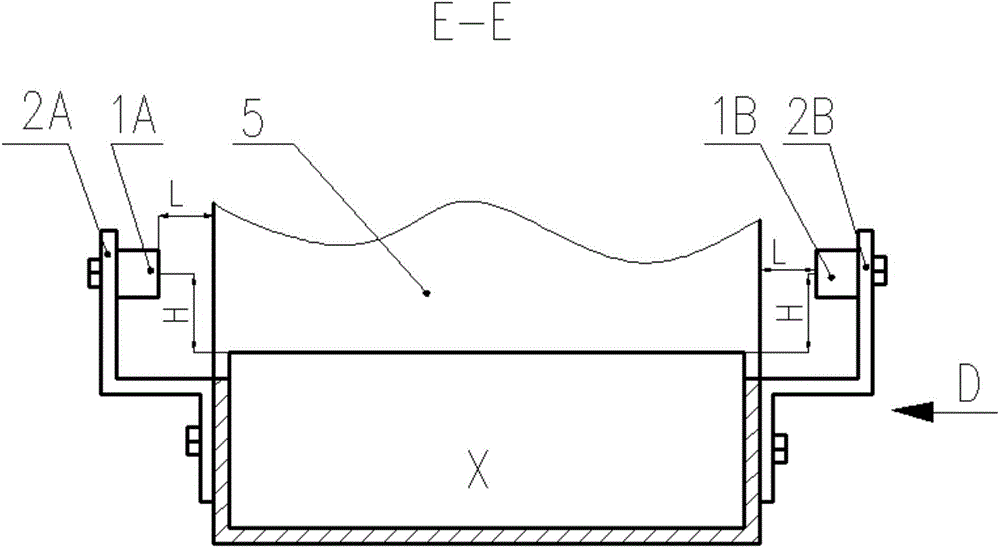

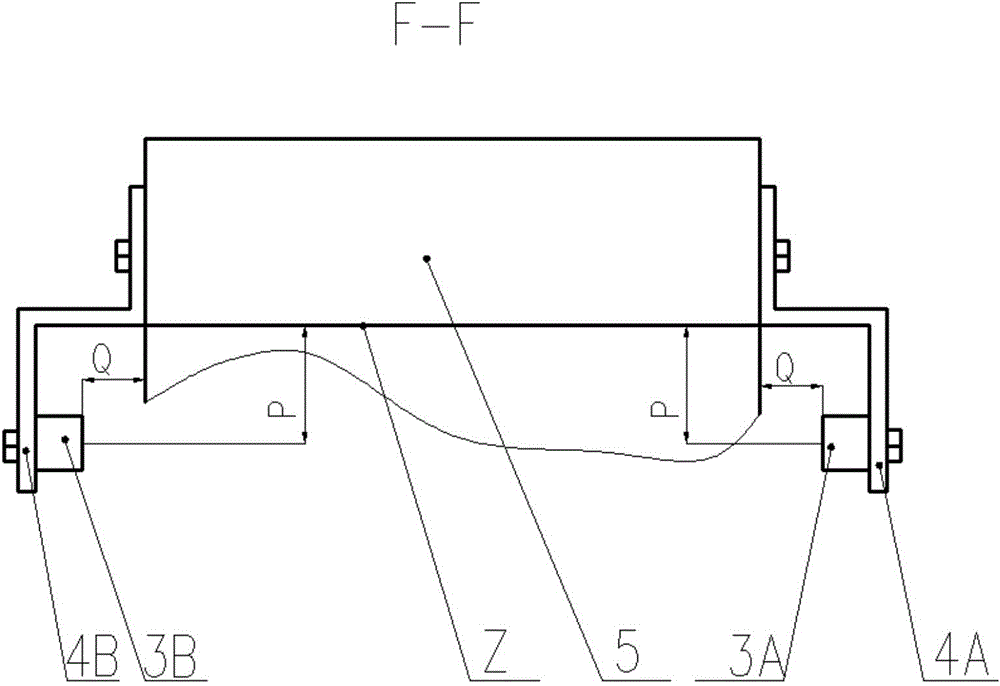

[0056] 1. The length of the selected light curtain sensor can be selected according to the size of the outlet and inlet of the chain plate chip conveyor;

[0057] 2. The installation distance of the light curtain sensor can be adjusted in a small range according to the needs, and the light curtain plane can cover the exit and entrance;

[0058] 3. The trigger time setting of the delay relay can be changed within a small range;

[0059] 4. Add some protective devices such as overcurrent and overload relays to the alarm circuit;

[0060] 5. Use PLC instead of time-delay electrical control, that is, use "soft relay" instead;

[0061] 6. The alarm device can be a transmitter or a warning light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com