Electronic gauge

An electronic metering and controller technology, applied in bottle filling, liquid bottling, packaging, etc., can solve the problems of easy scattering of liquid around, inaccurate weighing, and inability to apply to large-scale weighing production lines, etc. Accurate weighing and less error-prone results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

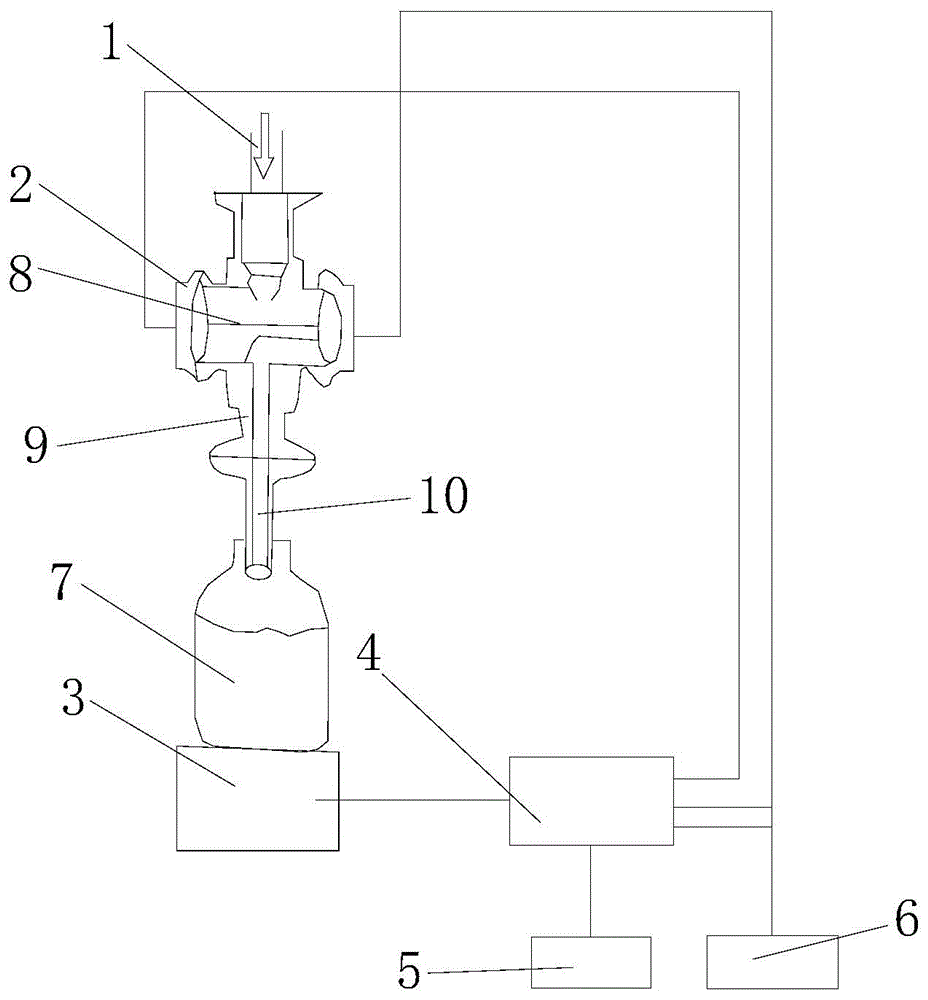

[0011] Such as figure 1 The shown electronic meter includes a liquid inlet pipe 1 and a filling valve 2. The filling valve 2 is arranged on the liquid inlet pipe 1, and the outlet of the liquid inlet pipe 1 is connected to the liquid receiving bottle 7. connected, the liquid receiving bottle 7 is placed on the load cell 3, the load cell 3 is connected to the controller 4 by a wire, the controller 4 is connected to the constant value device 5 by a wire, and the The controller 4 is also connected to both ends of the filling valve 2 through pipelines, and the controller 4 is also connected to the capacity display 6 through lines. The filling valve 2 includes a sleeve, and one end of the sleeve has a diverter plate 8, and the diverter plate 8 has a connection groove 9, and a flow guiding column 10 extending downward is arranged in the connection groove 9.

[0012] The working principle of the present invention is: when the liquid passes through the filling valve, due to the uniqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com