Autoclaved asphalt tailings slag brick and preparation method thereof

A technology for slag bricks and tailings slag is applied in the field of autoclaved asphalt tailings slag bricks and their preparation, and achieves the effects of being beneficial to comprehensive utilization, energy saving, good physical and mechanical properties and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

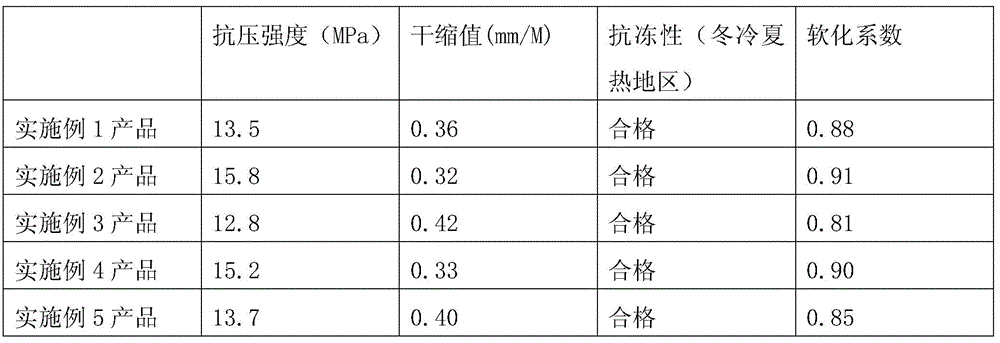

Examples

Embodiment 1

[0044] Raw materials: quicklime 800kg, cement 500kg, fine river sand 4000kg, asphalt tailings slag 4700kg

[0045] Put the above-mentioned raw materials into the high-speed mixer and add 750kg of water while stirring. After stirring evenly, send them to the digestion bin for digestion for 2 to 3 hours, and then put them into the high-speed blender in the order of entering the bin for secondary mixing and adding water to make the mixture The material becomes a billet with a water content of 8-10%, and the billet is sent to the HF1280 automatic hydraulic brick press to be pressed into a 240×115×53mm brick, and then the MD76 automatic coder is taken out from the brick press according to the regulations. Stacked on the autoclave trolley. The autoclaved trolleys that have been stacked with bricks are formed into a row, pulled into the autoclave by the tractor, the lid of the autoclave is closed, the air in the autoclave is exhausted (30 minutes), and the autoclave maintenance syste...

Embodiment 2

[0047] Raw materials: quicklime 1200kg, fine river sand 3000kg, medium river sand 1000kg, asphalt tailings slag 4800kg

[0048] Put the above raw materials into the high-speed mixer and add 750kg of water while stirring. After stirring evenly, send them to the digestion bin for digestion for 2-3 hours, and then put them into the high-speed mixer in the order of entering the bin for secondary mixing and adding water to make the mixture The material becomes a billet with a water content of 8-10%, and the billet is sent to the HF1280 automatic hydraulic brick press to be pressed into a 240×115×53mm brick, and then the MD76 automatic coder is taken out from the brick press according to the regulations. Stacked on the autoclave trolley. The autoclaved trolleys that have been stacked with bricks are formed into a row, pulled into the autoclave by the tractor, the lid of the autoclave is closed, the air in the autoclave is exhausted (30 minutes), and the autoclave maintenance system ...

Embodiment 3

[0050] Raw materials: quicklime 800kg, fine river sand 3500kg, asphalt tailings slag 5700kg

[0051] Put the above raw materials into the high-speed mixer and add 510kg of water while stirring. After stirring evenly, send them to the digestion bin for digestion for 2-3 hours, and then put them into the high-speed mixer in the order of entering the bin for secondary stirring and add water to make the mixed materials It becomes a billet with a water content of 8-10%, and the billet is sent to the HF1280 automatic hydraulic brick press to be pressed into a 240×115×53mm brick, and then removed from the brick press by the MD76 automatic stacker according to the regulations. code on the autoclave trolley. The autoclaved trolleys that have been stacked with bricks are formed into a row, pulled into the autoclave by the tractor, the lid of the autoclave is closed, the air in the autoclave is exhausted (30 minutes), and the autoclave maintenance system is set (heating for 1.5 hours, K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drying shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com