Edible vinegar sterilization cooling device

A technology for sterilization and cooling of edible vinegar, which is applied in the field of vinegar production equipment and edible vinegar sterilization and cooling devices, can solve the problems of affecting the taste and aroma of vinegar, affecting the storage time, and incomplete sterilization, so as to improve the filling process. Efficiency, Guaranteed Taste and Fragrance, Reduced Waiting Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

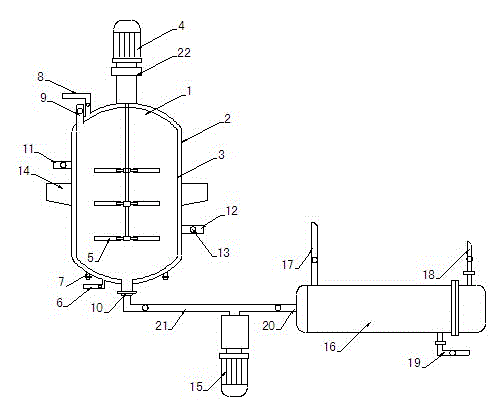

[0014] Depend on figure 1 Known, a kind of edible vinegar sterilizing cooling device is made up of reactor 1, pressurization pump 15, condenser 16, pipeline 21, and reactor 1 bottom is provided with outlet 10, and outlet 10 passes through pipeline 21 earlier and adds The pressure pump 15 is connected, and then connected with the condenser 16; the reaction kettle 1 is composed of a jacket 2, an inner tank 3, a stirring motor 4, a stirring paddle 5, and a reducer 22. The inner tank 3 is located in the jacket 2, and the stirring The motor 4 is installed above the jacket 2, and a reducer 22 is arranged under the stirring motor 4, and a stirring paddle 5 is arranged below the reducer 22 to extend into the inner tank 3; a steam inlet 11 is arranged on the upper side of the jacket 2, and a Steam outlet 12, oil inlet 8 and feed inlet 9 are respectively provided at the upper end of jacket 2, oil outlet 6, two or more electric heating rods 7 and outlet 10 are arranged at the bottom of j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com