Method for smelting high-phosphorus molten iron by duplex-slag remaining process

A slag retention method and high phosphorus technology, which is applied in the manufacture of converters, etc., can solve the problems of aggravated furnace lining erosion, low metal yield, and increased slag consumption, so as to ensure the dephosphorization effect, high molten steel yield, and The effect of increasing the yield of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

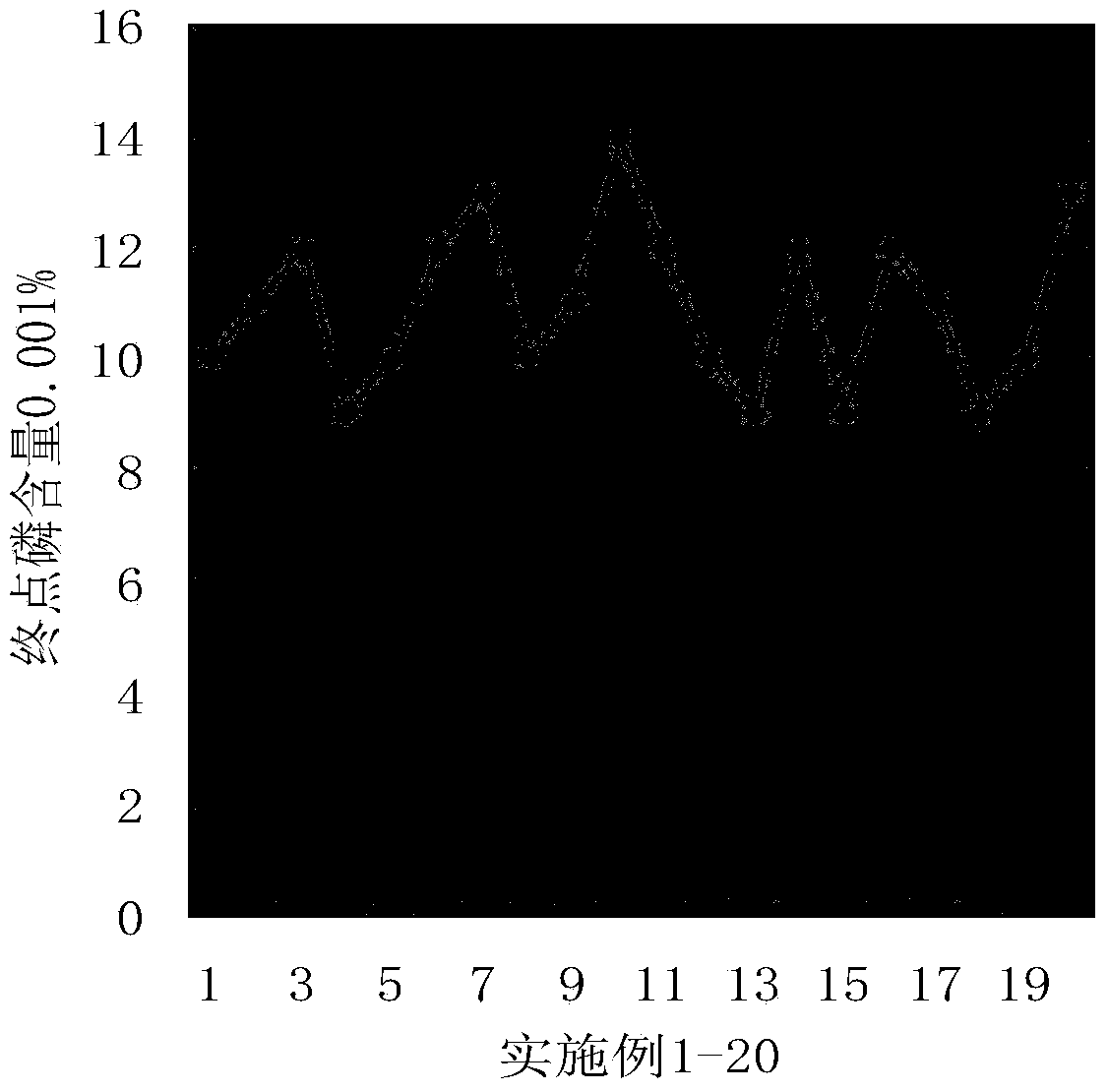

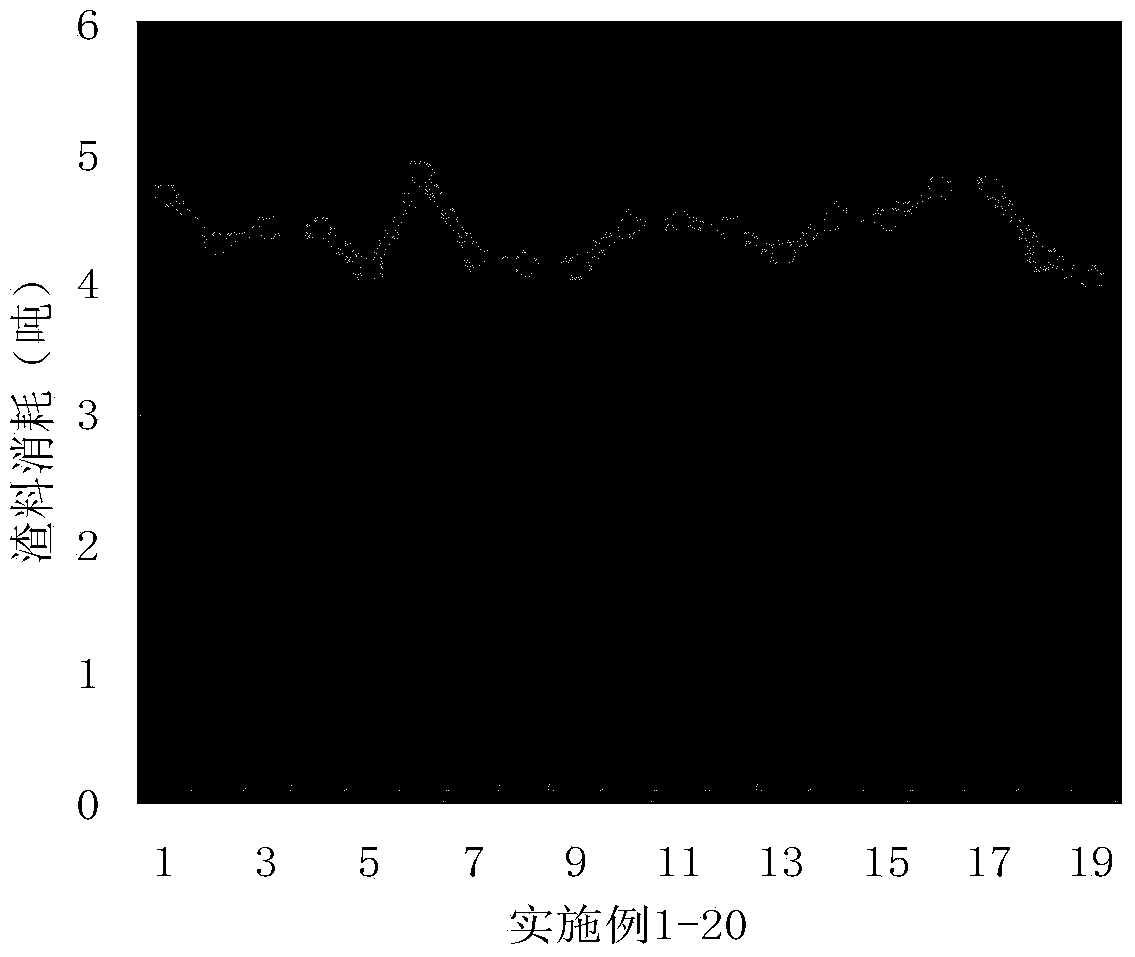

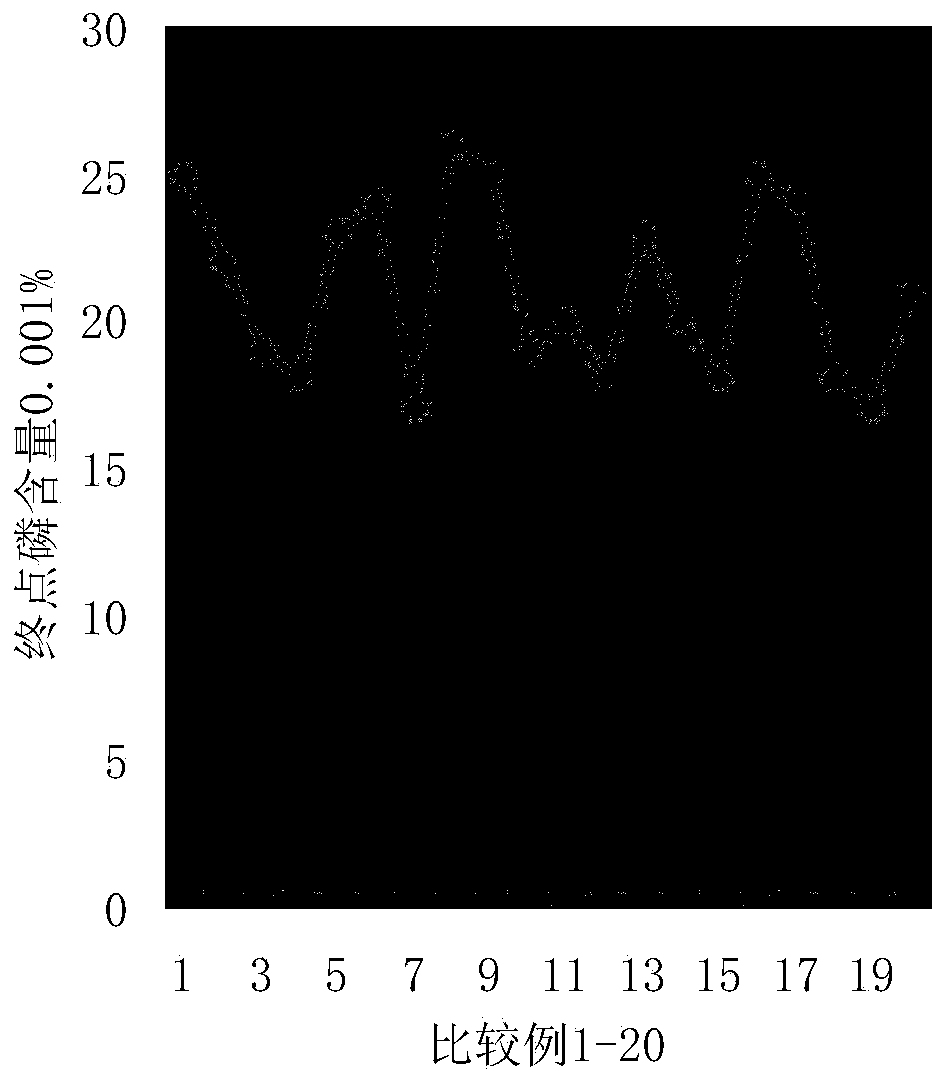

Embodiment 1-20

[0035] A method for smelting high-phosphorus molten iron by "double-linkage-leaving slag method", said method comprising the following steps:

[0036] 1) Dephosphorization smelting in converter 1: 100% of the decarburization smelting slag is used for dephosphorization smelting with iron ore; during the smelting process, the first batch of slag for dephosphorization is made of lime, sintered ore and iron vanadium, and the lime is always added The amount is 15-20kg / t, the amount of sinter added is 1 / 2 of the total amount of sinter added in dephosphorization smelting, and the bauxite is 400-600kg; ~1.30m, the gun position at the end is kept at 1.2m, the process oxygen pressure is 0.50~0.60MPa, and the process oxygen flow rate is 14500Nm 3 / h, the total oxygen consumption in the process is 3000~3200Nm 3 , the flow rate of bottom blowing mode is 1800Nm 3 / h; Add two batches of limestone after slagging, each batch of limestone is 400-500kg; after the end of the dephosphorization s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com