Process for recycling hot refining slag in converter smelting process

A converter smelting and refining slag technology, which is applied in the manufacture of converters, etc., can solve the problems of metal loss, slag treatment cost, refining slag environmental pollution, high steelmaking cost, etc., to reduce power consumption, high promotion value, and reduce converter steel materials The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] The invention is a technology for reusing hot refining slag in the converter smelting process, which fully utilizes the physical heat of the refining slag and reduces the temperature impact of adding cold refining slag on the converter blowing early stage.

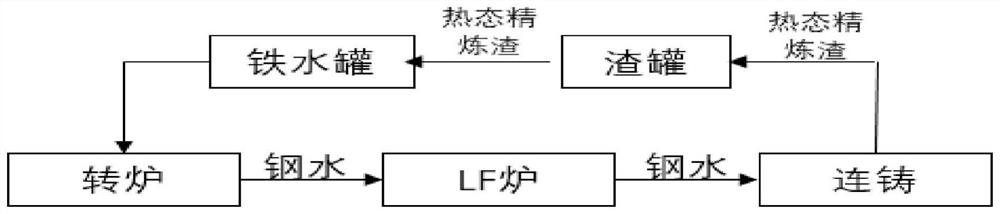

[0027] The thermal state of LF furnace refining slag is utilized in the process of converter smelting such as figure 1 shown, including:

[0028] S1. The molten steel obtained from the LF furnace enters the continuous casting process, and the resulting hot continuous casting ladle casting residual refining slag is divided into two parts for processing, and the molten steel is poured into the slag pot at the part of the molten steel, and the slag is stopped after the steel flow is seen, and the remaining part is refined The slag and molten steel are all folded into the refining ladle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com