Combined hammer head for hydraulic pile hammer

A combined hammer and hydraulic technology, which is applied to sheet pile walls, buildings, foundation structure engineering, etc., can solve the problem of easily breaking piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

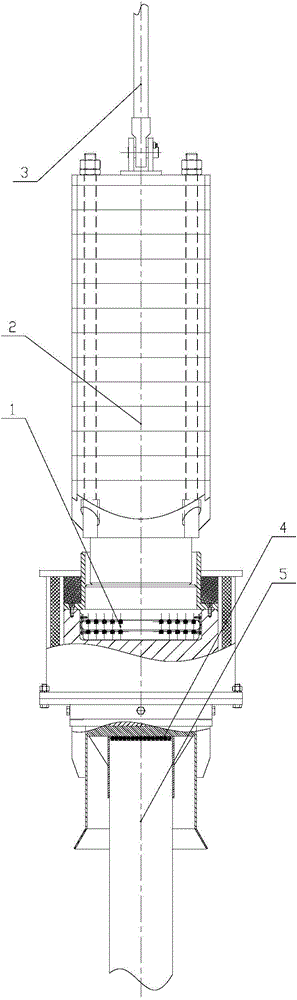

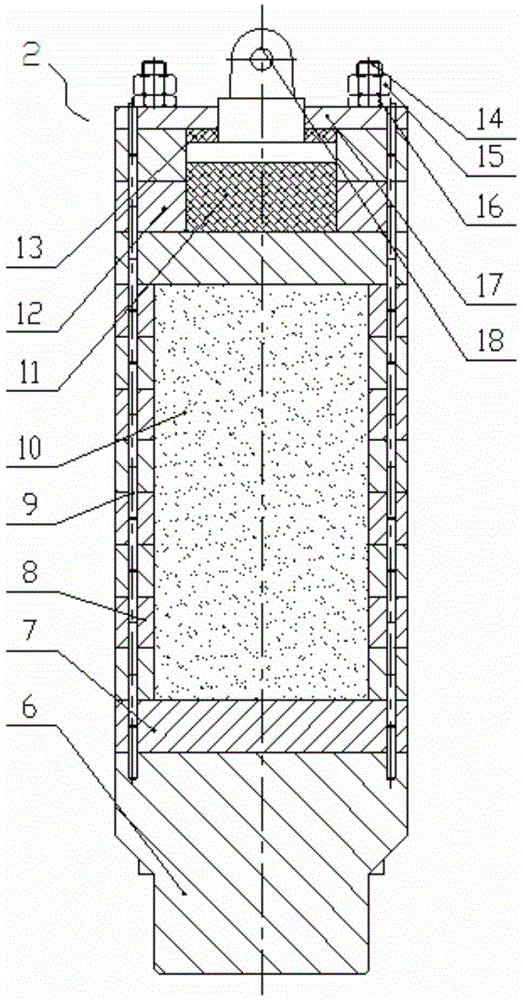

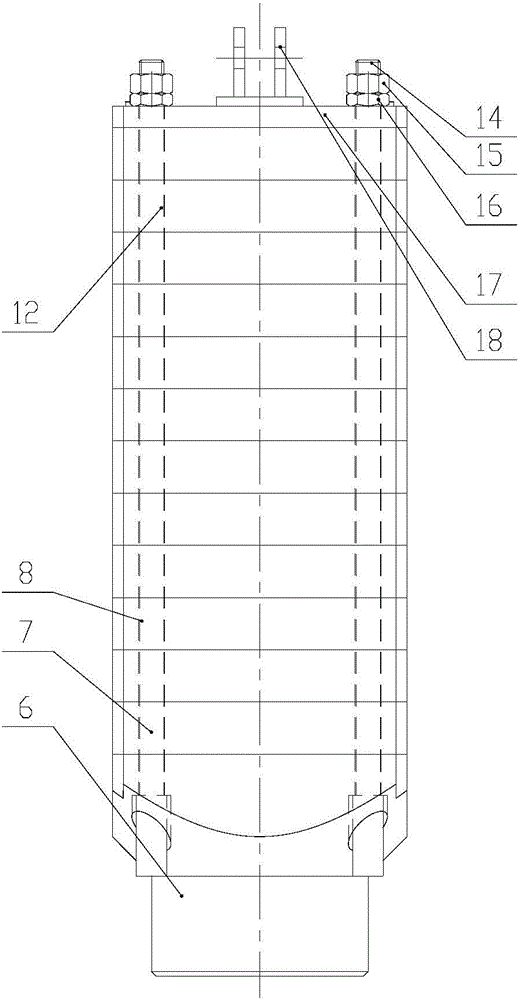

[0026] see in conjunction figure 2 and image 3 , a combined hammer head 2 for a hydraulic piling hammer with a built-in metal particle filler consists of an impact head 6, a lower plate 7, a middle plate 8, a positioning pin 9, a metal particle filler 10, a bottom cushion 11, an upper plate 12, a top Cushion pad 13, bolt 14, thick nut 15, thin nut 16, pressure plate 17 and oil cylinder connecting seat 18 etc. parts are formed. Wherein, the hammer body of the hammer head 2 is formed by the impact head 6, the lower plate 7, the middle plate 8, the upper plate 12, and the pressure plate 17, which are positioned by the positioning pin 9 and connected with the bolt 14. The bottom of the bolt 14 is screwed on the impact head 6. On the screw hole, the hammer body is locked into a whole by thick nut 15 and thin nut 16 at the top, and filler 10 is filled in the hollow cavity of the hammer body surrounded by the middle plate 8, and is sealed by the lower plate 7 and the upper plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com