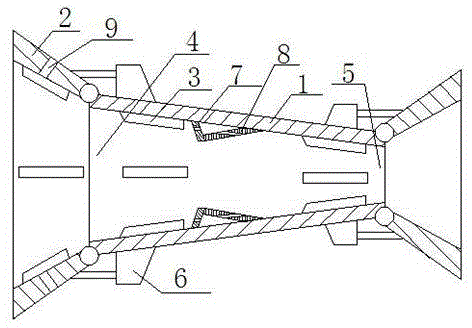

Water flow speed increasing device for bulb tubular generator set

A speed-increasing device and generator set technology, which is applied in the direction of reaction engines, hydroelectric power generation, machines/engines, etc., can solve the problems of reduced flexibility, weak water flow guidance ability, and weak water flow speed-up ability, so as to avoid irregular impact , the structure is simple and reasonable, and the speed-up effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Compared with the traditional water flow speed-up equipment, the present invention has a simpler and more reasonable structure, and the speed-up effect is more significant. At the same time, it also has the functions of actively adjusting the speed-up and actively draining and diverting the water flow, so that on the one hand, it is convenient On the other hand, the water flow speeds up, and on the other hand, it also avoids irregular impacts on subsequent generator sets caused by turbulent flow, which helps to improve the stability of generator operation.

[0015] The basic principles and main features of the present invention and the advantages of the present invention have been shown and described above. Those skilled in the industry should understand that the present invention is not limited by the above-mentioned embodiments. What are described in the above-mentioned embodiments and the description only illustrate the principle of the present invention. Without depa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com