Power-assisted transmission structure for traveling machine

A technology for power-assisted transmission and machinery, which is applied in control devices, transportation and packaging, vehicle components, etc., can solve the problems of complex structure of power-assisted transmission, high energy consumption, low work efficiency, etc., to avoid energy consumption and resistance, reduce The effect of low energy consumption and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

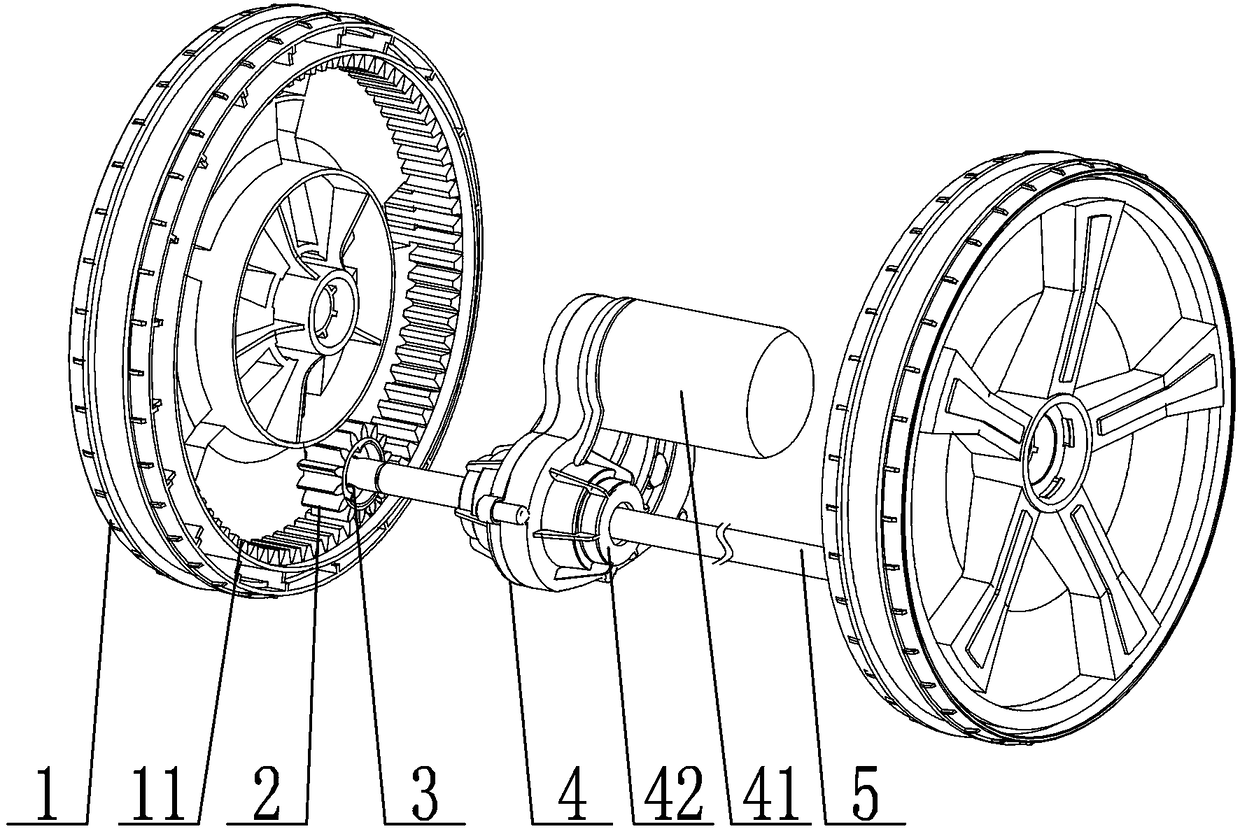

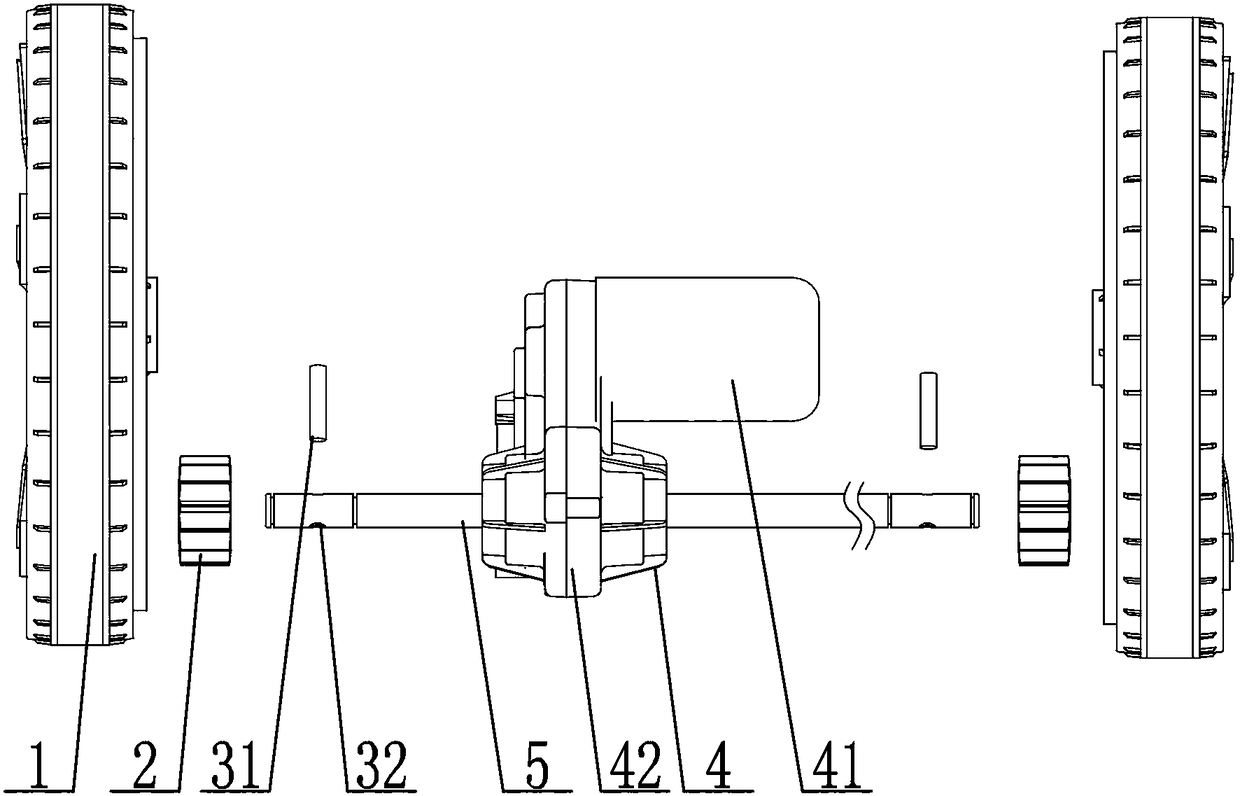

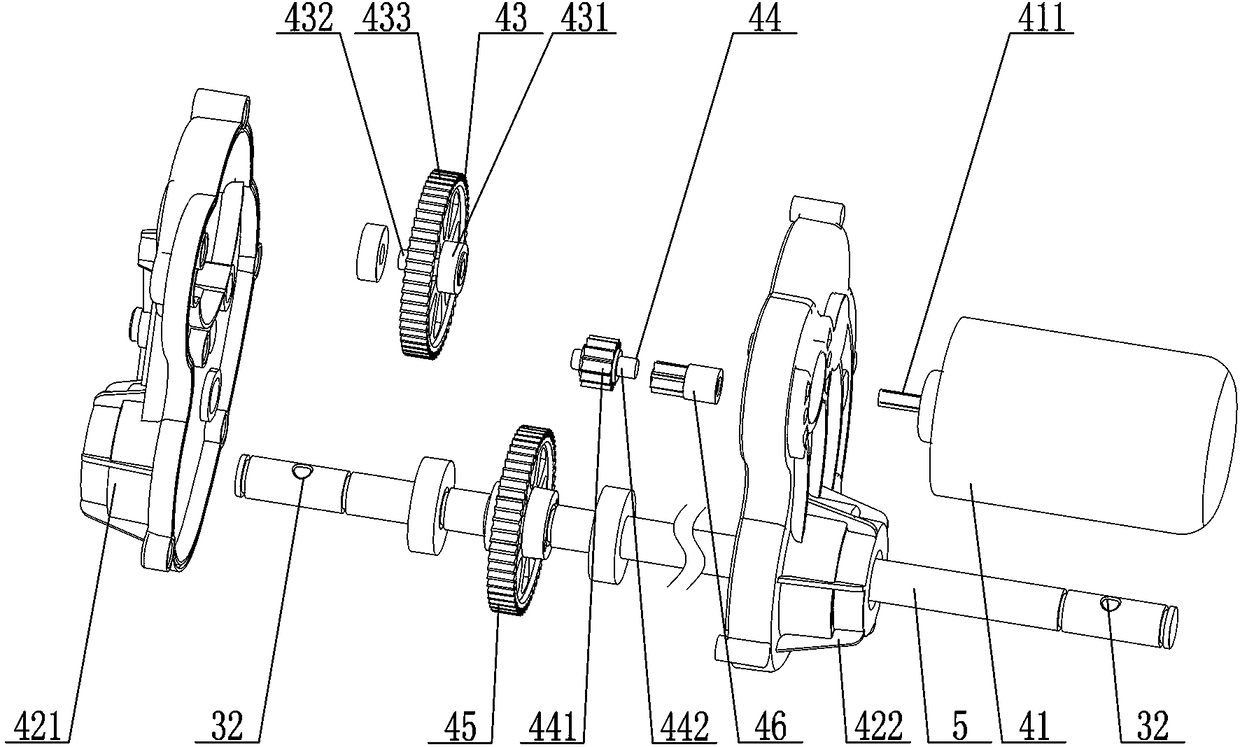

[0041] A power-assisted transmission structure of a traveling machine, comprising a power-assisted transmission device 4, a power-assisted output shaft 5, and a walking wheel 1, the power-assisted transmission device 4 provides driving assistance for the walking wheel 1 through the power-assisted output shaft 5, and the power-assisted transmission device The transmission device 4 includes a casing 42, a driving motor 41, and the driving motor 41 is connected to the casing 42. The power-assisted transmission device 4 also includes a driving gear assembly 43, an output gear 45, and a floating gear assembly 44. The driving gear The component 43 and the output gear 45 are respectively rotatably connected in the casing 42, the driving gear component 43 is driven by the driving motor 41, the output gear 45 is arranged on the power output shaft 5, and the floating gear component 44 meshes with the driving gear assembly 43, and a sliding track 47 is also provided in the casing 42. The ...

Embodiment 2

[0053] On the basis of Embodiment 1, as a preference, it also includes a one-way gear 2, and the inner side of the walking wheel 1 is also provided with a connecting tooth track 11, and the one-way gear 2 is connected to the connecting tooth track 11 of the walking wheel 1. meshing, a one-way drive structure 3 is provided between the one-way gear 2 and the booster output shaft 5, and the booster output shaft 5 drives the one-way gear 2 to rotate in one direction through the one-way drive structure 3 .

[0054] Preferably, the one-way driving structure 3 includes a transmission pin 31, a ratchet slideway 21, and a sliding through hole 32. In the one-way gear 2 , the transmission pin 31 is slidingly connected with the sliding through hole 32 and the end of the transmission pin 31 is matched with the ratchet slideway 21 in the one-way gear 2 .

[0055] Preferably, the length of the transmission pin 31 is smaller than the diameter of the ratchet top circle 22 of the ratchet slidew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com