Telescopic arm device

A telescopic arm, direct motion technology, applied in the direction of transmission, claw arm, manufacturing tools, etc., can solve the problems of long time, difficulty, and full height of lifting and moving, and achieve the effect of simplifying installation difficulty, simplifying structure, and facilitating production and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

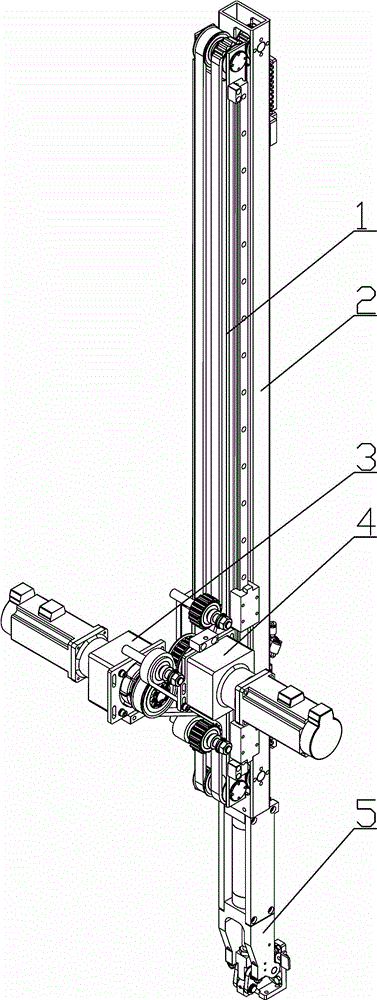

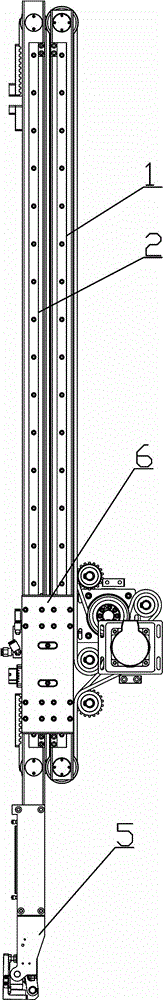

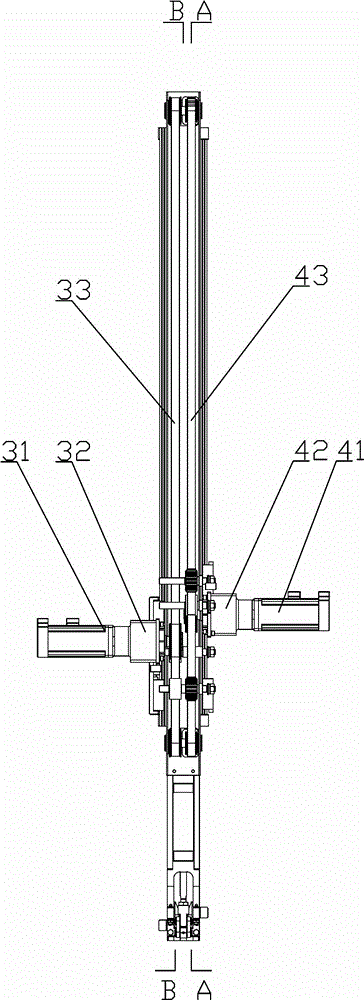

[0026] Such as Figure 1~5 Among them, a telescopic arm device includes a fixed part 6, the fixed part 6 is usually installed on the frame, the first direct-moving part 1 and the fixed part 6 are slidably connected, and the connection between the second direct-moving part 2 and the first direct-moving part 1 between the sliding connection; the second direct-acting part 2 and the first direct-acting part 1 can slide relative to the fixed part 6 along its own length direction, but the first direct-acting part 1 cannot break away from the constraint range of the fixed part 6, and the second Relative sliding between the straight-acting part 2 and the first direct-acting part 1 is possible, wherein the second direct-acting part 2 can break away from the constraint range of the fixing part 6 , but cannot break away from the constraint orientation of the first direct-acting part 1 . With this structure, when the telescopic arm device is fully extended, it is almost equivalent to twic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com