Method for establishing rolling blade die cavity

A technology for rolling blades and molds, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as poor cavity accuracy of rolling blade molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

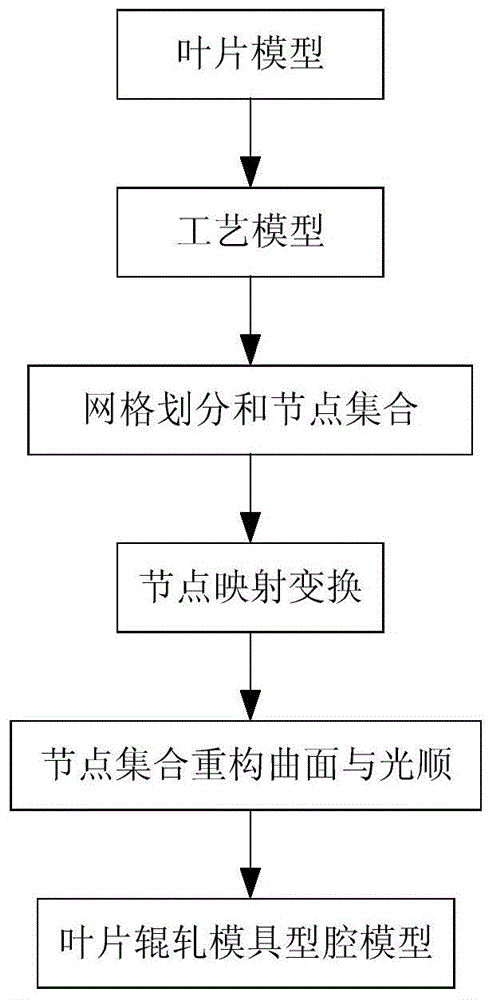

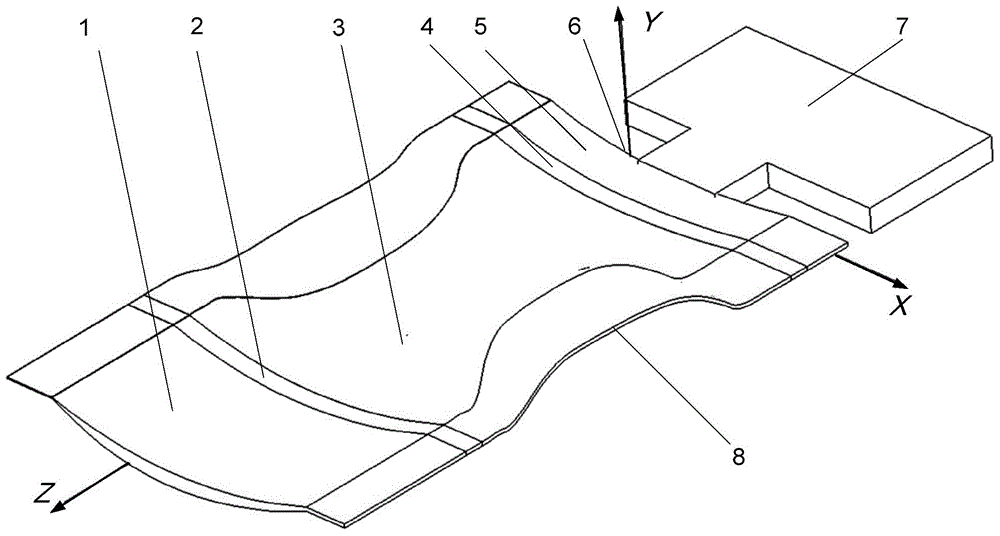

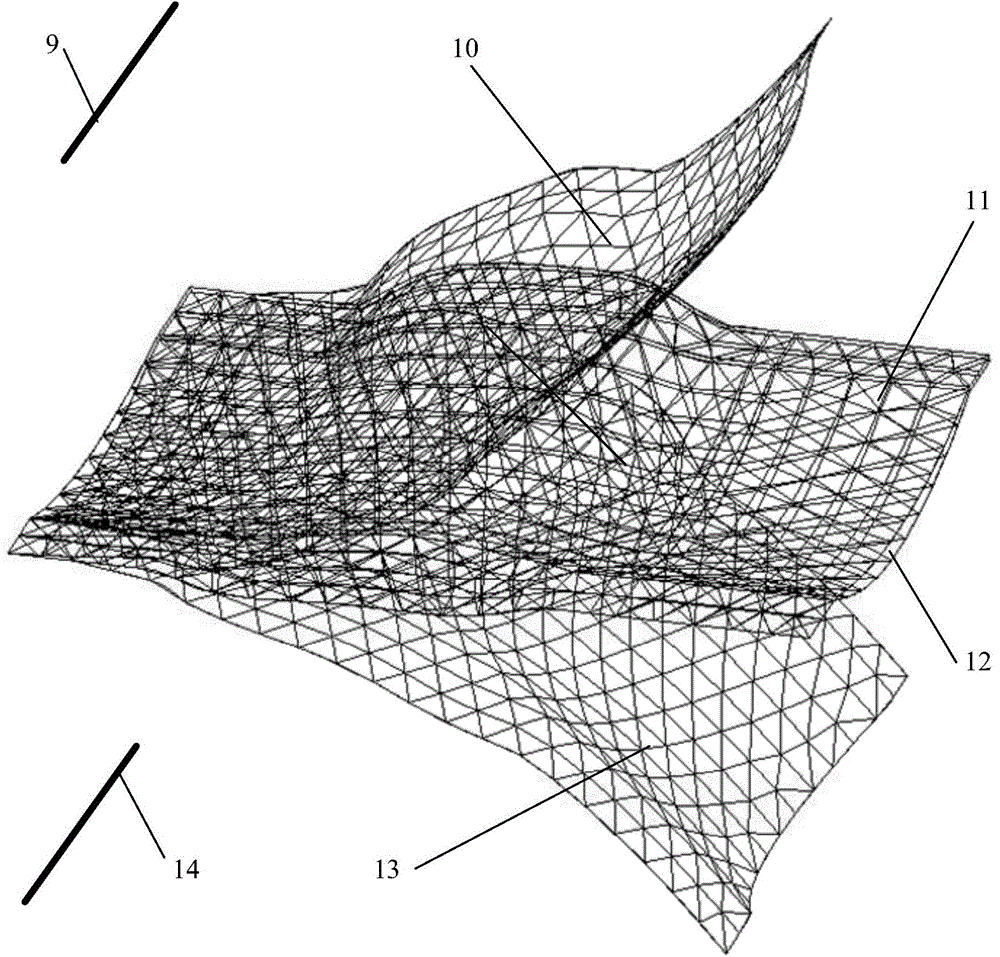

[0027] refer to Figure 1-3 . The present invention sets up the method concrete steps of rolling blade mold cavity as follows:

[0028] The present invention is described in detail by taking the establishment of the compressor blade rolling mold cavity model in UG NX7.0 software as an example.

[0029] Step 1: Start the UG NX7.0 modeling module, import the compressor blade model 3, and extend the blade tip along the opposite direction of the blade body to half the maximum diameter of the inscribed circle of the section line, which is Cmax / 2, to form the blade tip process transition 2, Build the leaf-root process transition4. Extract the tip section line of the blade tip process transition 2 and offset it 5 times in reverse along the blade body with a spacing of 2 mm, and establish a solid body through the offset section line group to form the blade tip process compensation 1. Extract the 4 root-end section lines of the blade root process transition and offset them three tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com