Containment Recirculation System

A recycling system and containment technology, applied in the field of nuclear technology safety equipment, can solve the problem of no filtration, and achieve the effects of reducing impact, reducing radioactivity, and reducing the release of fission products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

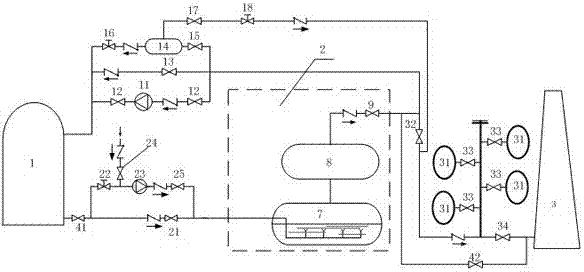

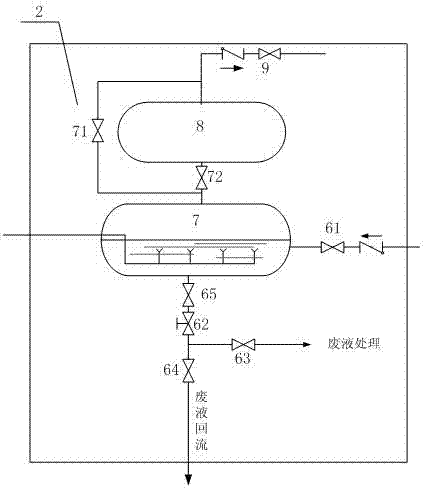

[0037] like figure 1 As shown, the containment recirculation system includes a containment vessel 1, a containment filtration and discharge system 2 (CFS), an air discharge mechanism 3 connected in sequence, and an air discharge mechanism 3 for the temporary storage of the containment filtration and discharge system 2. The retention pipeline of the gas, used to return the gas discharged from the outlet of the containment filter discharge system 2 or the gas temporarily stored on the retention pipeline to the return line of the containment vessel 1, used to discharge the gas in the containment vessel 1 to the containment vessel Pressure relief line for filter discharge system 2.

[0038] The upstream of the return pipeline is connected to the outlet of the containment filtration and discharge system 2, and the downstream is connected to the inner space of the containment vessel 1; the upstream of the retention pipeline is connected to the outlet of the containment filtration an...

Embodiment 2

[0043] On the basis of Embodiment 1, this embodiment further explains the return pipeline:

[0044] The return pipeline includes three parallel pipelines, the first pipeline is provided with a return fan 11 and two control valves A12, the return fan 11 is arranged between the two control valves A12; the second pipeline is provided with a third isolation valve 13. The third pipeline is provided with a control valve K15, a pressure buffer tank 14, and a second flow regulating valve 16 in sequence. The control valve K15 is connected to the outlet of the containment filtration and discharge system 2. Spatial connectivity.

[0045] The containment vessel 1 can be actively discharged through the pressure relief pipeline to alleviate the threat of containment overpressure and hydrogen, and maintain the integrity of the containment vessel 1. The main purpose of setting the return pipeline in this embodiment is to filter the discharged gas from the containment filter and discharge syst...

Embodiment 3

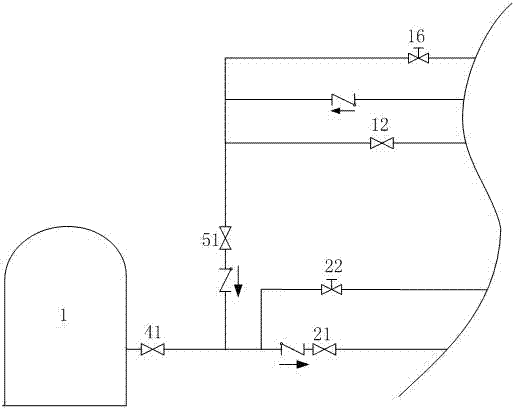

[0055] On the basis of Embodiment 1, the pressure relief pipeline is further improved in this embodiment:

[0056] The pressure relief pipeline includes two parallel pipelines and a minimum flow pipeline; the two parallel pipelines are active and passive pressure relief pipelines respectively, the upstream of the two parallel pipelines are connected downstream of the first isolation valve 41, and the downstream is connected to the The inlet of the filter discharge system 2 is connected; one of the pipelines (passive pressure relief pipeline) is provided with a control valve B21, and the other pipeline (active pressure relief pipeline) is sequentially provided with a first flow regulating valve 22 along the direction of gas flow , exhaust fan 23, control valve C25, the exhaust fan 23 is located between the first flow regulating valve 22 and the control valve C25; the minimum flow pipeline is connected after the first flow regulating valve 22, and the minimum flow pipeline is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com