Stator coil corona preventing structure of highland high-voltage asynchronous motor

A technology for asynchronous motors and stator coils, applied to the shape/style/structure of winding insulation, which can solve problems such as coil chemical corrosion, winding burnout, and motor damage, and achieve simple operation, reasonable structure, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

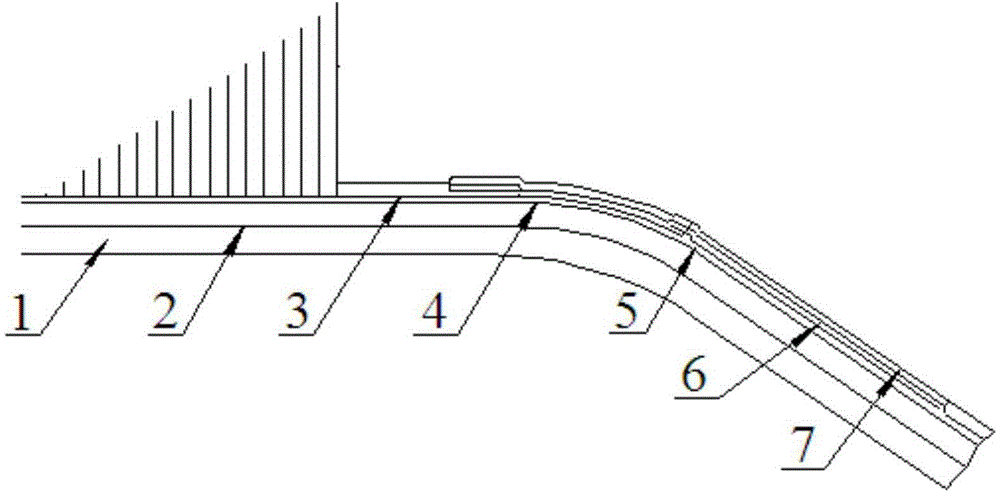

[0012] see figure 1 , a stator coil anti-corona structure of a high-voltage asynchronous motor for plateaus, including a coil body 1, the straight section and the curved section of the coil body 1 are wrapped with a first mica tape 2, and the first mica tape located outside the straight section of the coil body 1 The outside of the band is wrapped with a low-resistance band 3 through a half-fold, and the outside of the first mica band located in the curved section of the coil body 1 is wrapped with a middle-resistance band 4 through a half-fold, and the outside of the low-resistance band 3 and the middle resistance band 4 are wrapped with a high-resistance band through a half-fold. The resistance band 5 and the high resistance band 5 are wrapped with a second mica band 6, and the second mica band 6 is wrapped with a one-way breathable protective band 7 through a half-fold.

[0013] In the present invention, the first mica tape 2 is a mica tape with less rubber powder; the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com