Pushrod assembly for a medium voltage vacuum circuit breaker

A vacuum circuit breaker and push rod technology, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problem that the minimum size of push rod components cannot be reduced any more

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

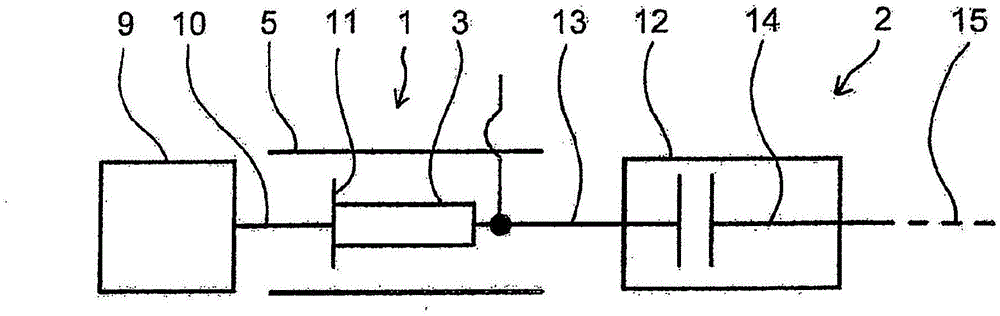

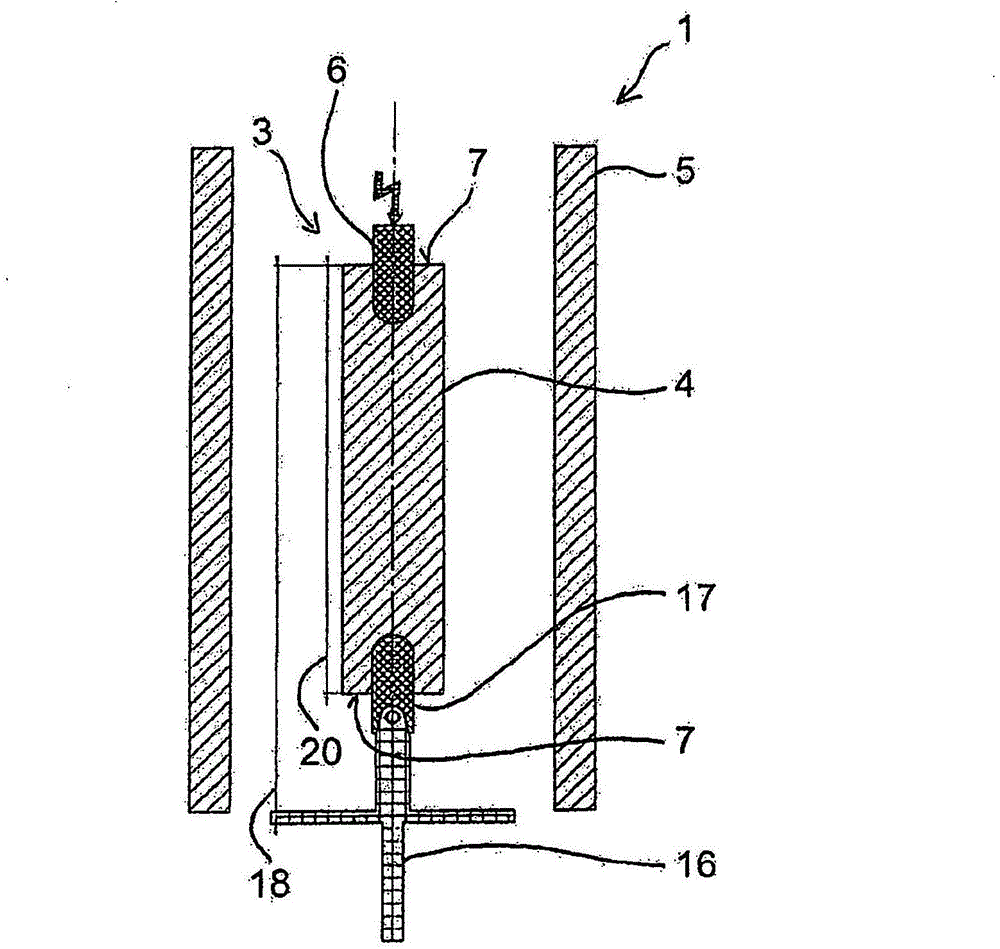

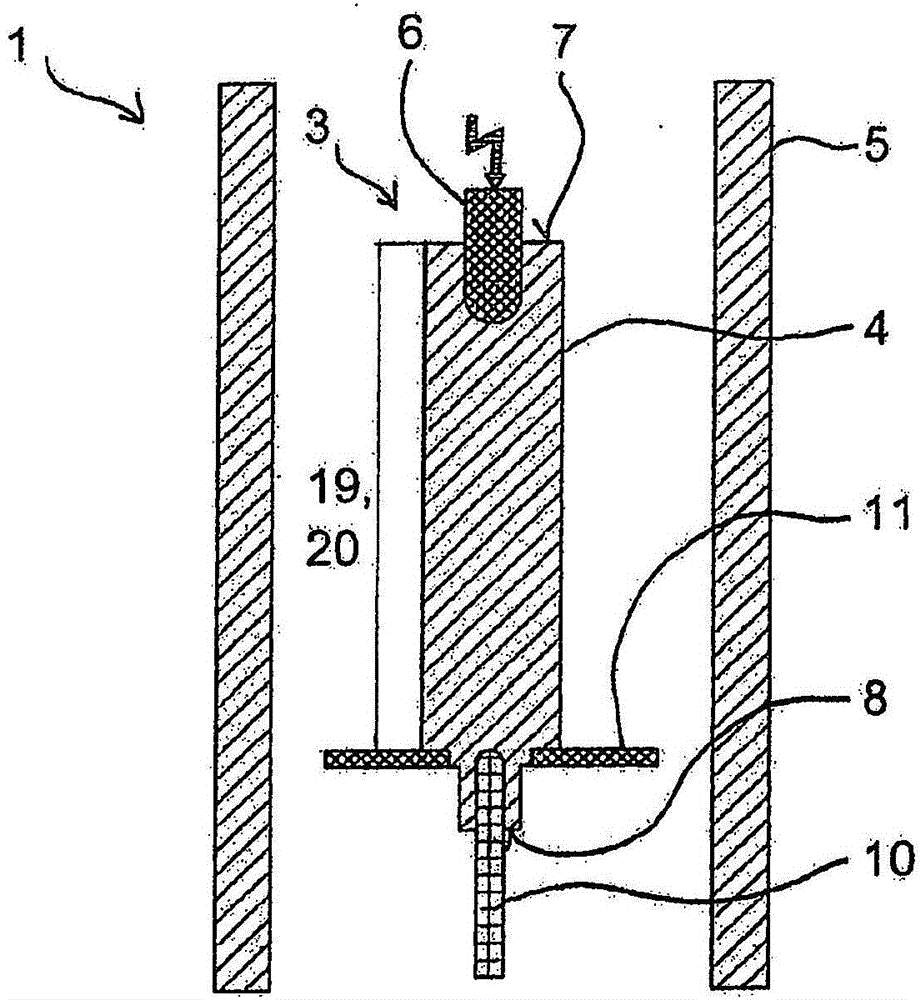

[0025] Such as figure 1 As shown in , the medium voltage vacuum circuit breaker 2 according to the embodiment of the present invention mainly includes a push rod assembly 1, which is mechanically connected with the electromagnetic actuator 9 on one side and connected with the vacuum switch chamber 12 on the other side. mechanical connection. The connection between the push rod assembly 1 and the electromagnetic actuator 9 is realized through a guide pin 10 . The guide pin 10 mechanically connects the push rod 3 of the push rod assembly 1 with the electromagnetic actuator 9 . The push rod 3 is surrounded by an insulating housing 5 which can also surround a switching chamber 12 . The connection between the push rod assembly 1 and the vacuum switch chamber is realized through the movable conductive terminal 13 . The push rod 3 can move along the axis 15 so as to connect and disconnect the movable conductive terminal 13 from the non-movable conductive terminal 14 .

[0026] Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com