Organic high-pressure-resistant borehole sealing resin and preparation method thereof

A sealing resin and anti-high pressure technology, which is used in the field of drilling sealing resin and preparation, can solve the problem of failure to meet the high pressure resistance requirements of hydraulic fracturing drilling, the limited sealing effect of rock mass cracks around the drilling, and the adhesion of the drilling wall. Weak ability and other problems, to save waiting time, improve the success rate of sealing holes, and improve the strength of high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

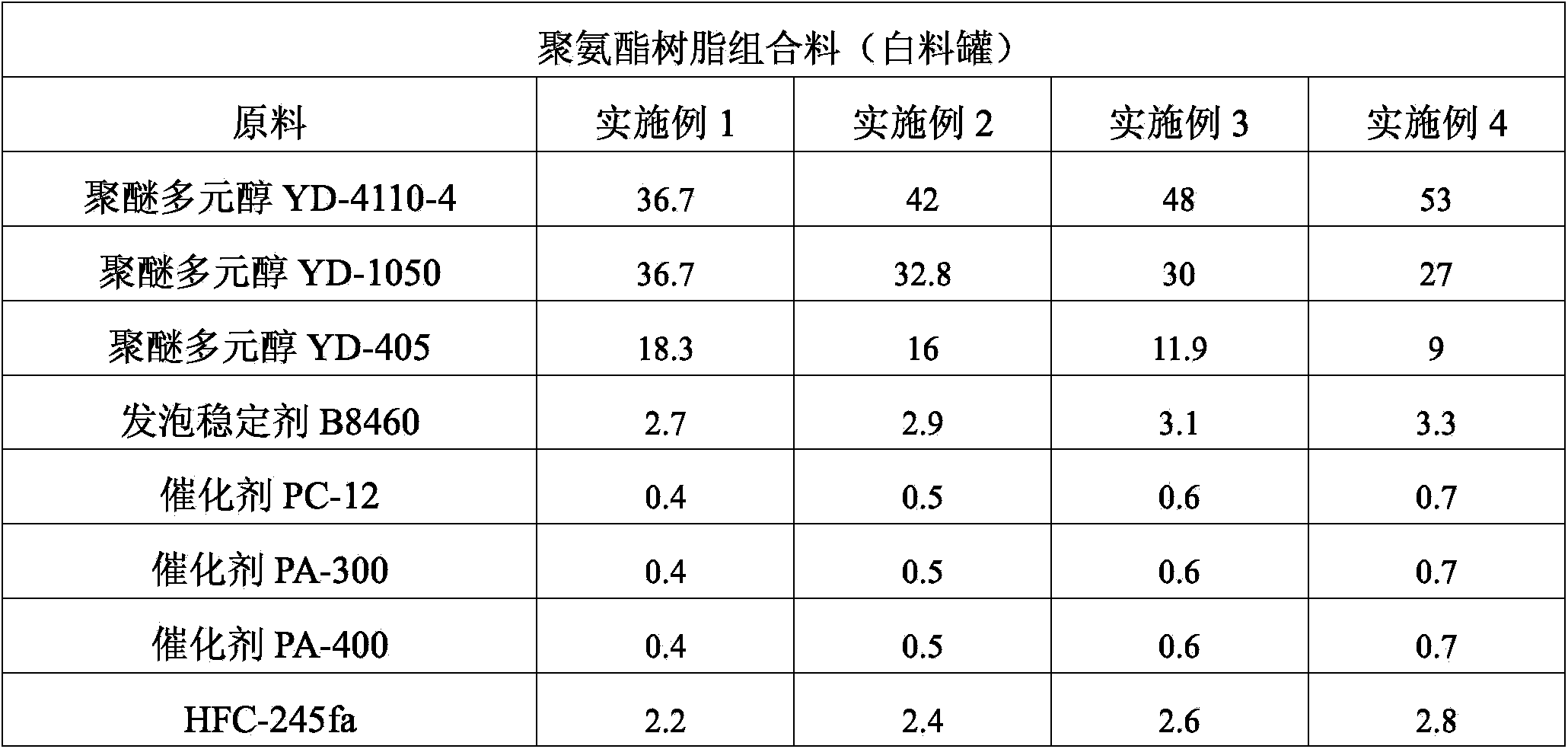

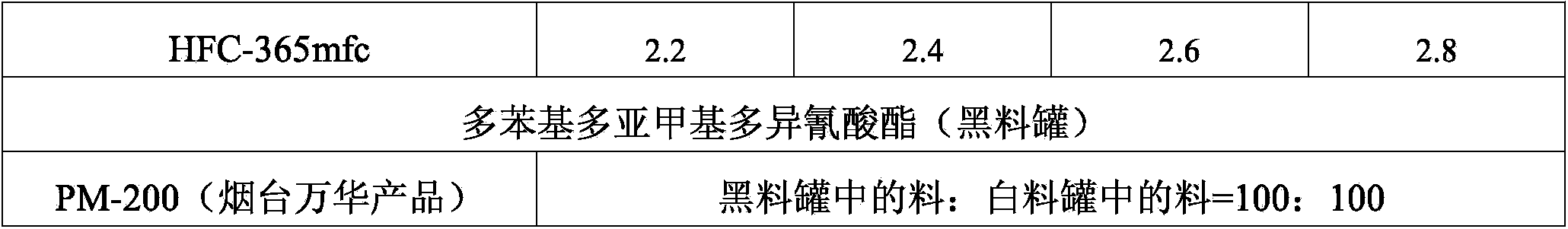

Embodiment 1

[0050] Embodiment 1: the density of the material in the white material tank is 1.09 ± 0.01g / cm 3 , The viscosity of the material is 230~265cps (22°C).

[0051] Preparation method: Mix 100 parts of white material in the white material tank with 100 parts of black material in the black material tank, react by mechanical stirring, and the free foaming density is 523kg / m 3 , The starting time is 200-205 seconds, the drawing time is 484-502 seconds, and the non-stick time is 814-828 seconds; the finished product has no shrinkage deformation, the expansion ratio is 2.1 times, and the compressive strength is 14.1MPa.

Embodiment 2

[0052] Embodiment 2: the density of the material in the white material tank is 1.08 ± 0.01g / cm 3 , The viscosity of the material is 220~254cps (22°C).

[0053] Preparation method: Mix 100 parts of white material in the white material tank with 100 parts of black material in the black material tank, react by mechanical stirring, and the free foaming density is 423kg / m 3 , The starting time is 195-201 seconds, the drawing time is 478-494 seconds, and the non-stick time is 805-820 seconds; the finished product has no shrinkage deformation, the expansion ratio is 2.6 times, and the compressive strength is 12.6MPa.

Embodiment 3

[0054] Embodiment 3: the density of the material in the white material tank is 1.07 ± 0.01g / cm 3 , The viscosity of the material is 209~244cps (22°C).

[0055] Preparation method: Mix 100 parts of white material in the white material tank with 100 parts of black material in the black material tank, react by mechanical stirring, and the free foaming density is 334kg / m 3 , The starting time is 191-198 seconds, the drawing time is 470-487 seconds, and the non-stick time is 797-811 seconds; the finished product has no shrinkage deformation, the expansion ratio is 3.3 times, and the compressive strength is 11.3MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com