Food processing grinder

A food processing and pulverizer technology, applied in the field of kitchen utensils, can solve the problems of slag accumulation, reduce the service life of the motor, increase the temperature of the motor, etc., and achieve the effects of reducing vibration, reducing noise, and increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the drawings and embodiments:

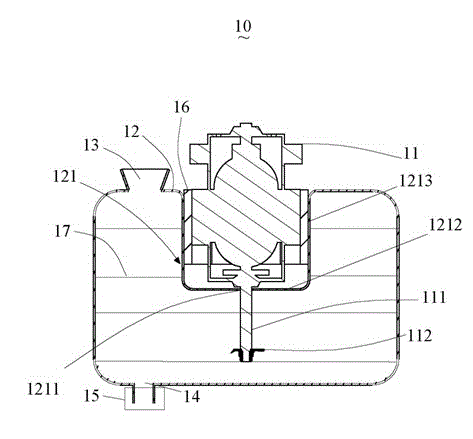

[0019] figure 1 The illustrated embodiment of the invention.

[0020] Such as figure 1 As shown, the food processing pulverizer 10 includes a motor 11, a pulverizing knife bar 111, a pulverizing knife 112, a processing container 12, an inner recess 121, a feed port 13, a pulp port 14, a valve 15, and a heat transfer medium 16. .

[0021] The motor 11 includes a crushing knife bar 111 and a crushing knife 112, and the crushing knife 112 is arranged at the end of the crushing knife bar 111. The motor 11 drives the crushing knife 112 to crush the pulping materials.

[0022] The processing container 12 is recessed to form an inner recess 121 which further includes a bottom wall 1212 and a side wall 1213. The bottom wall of the inner recess 121 penetrates through a shaft hole 1211 for the pulverizing knife rod to pass through. The motor 11 of the pulv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com