Double-hole copper bar mould

A hole copper and mold technology, which is applied in the field of double-hole copper bar molds, can solve problems such as complex processes and rough products, and achieve the effects of simple production methods, reduced complex processes, and accurate positions of double holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

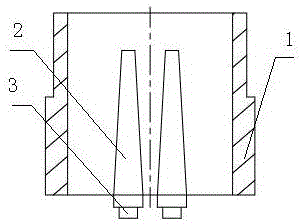

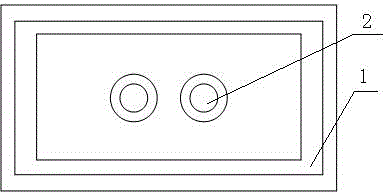

[0009] Such as figure 1 , figure 2 Shown: a double-hole copper bar mold, including a graphite forming die 1, the vertical section of the graphite forming die 1 is "convex" shape, the cross section of the graphite forming die 1 is square, and two heels are arranged in the cavity of the graphite forming die 1 The graphite core column 2 is fixed on the base of the graphite forming mold through graphite bolts 3, and the graphite core column 2 is a frustum with a narrow top and a wide bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com