Conveying and supporting table in vacuum glass soldering and sealing chamber

A technology of vacuum glass and support table, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., to achieve the effect of uniform pressure, not easy to deform, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

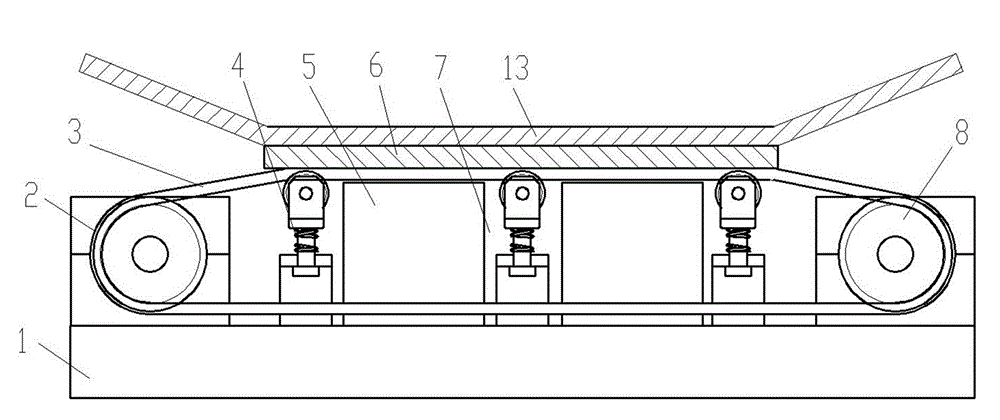

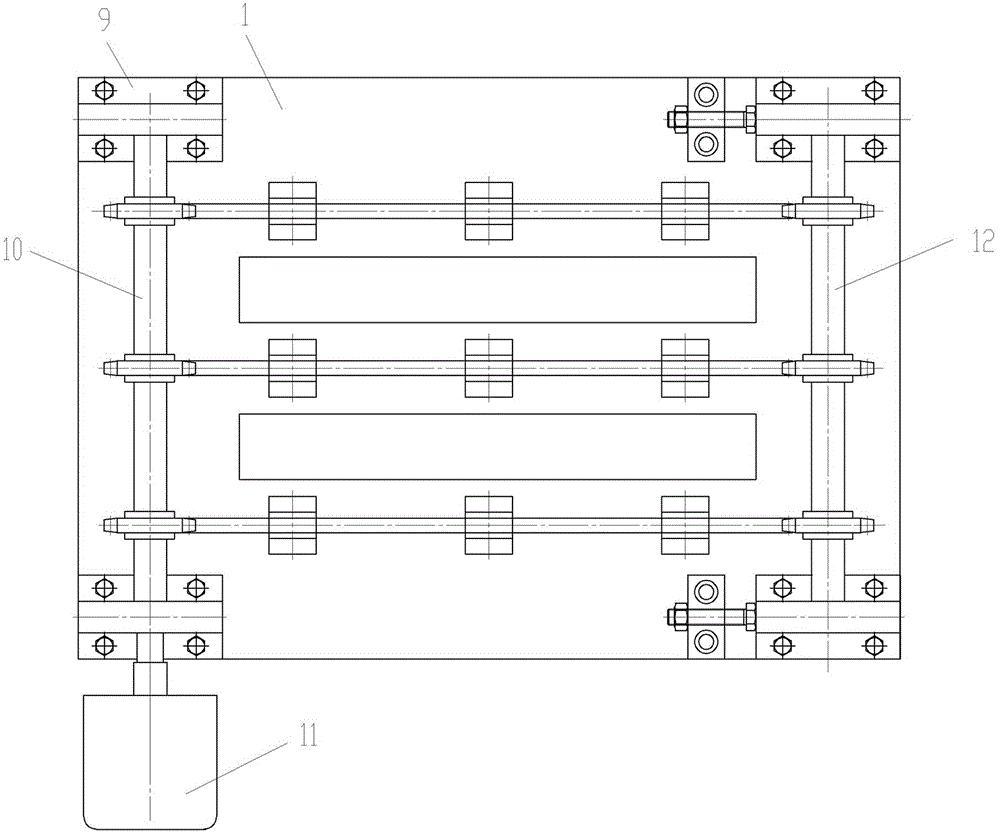

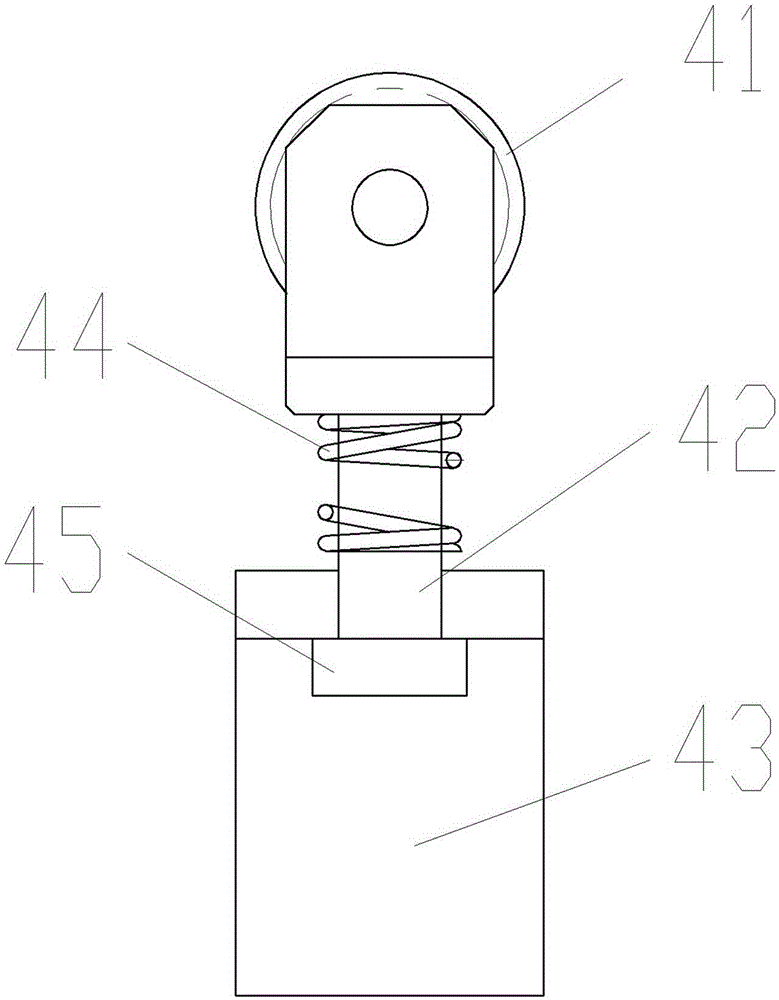

[0020] like figure 1 , figure 2 and image 3 As shown, it is a specific embodiment of a conveying support platform in a vacuum glass sealing and welding chamber according to the present invention. The conveying supporting platform is arranged on the equipment base 1 in the sealing and welding chamber of vacuum glass. The supporting platform includes a chain conveying mechanism and a rigid supporting platform 5, and the chain conveying mechanism comprises a chain wheel set 2, a power mechanism 11, rotating shafts 10, 12 and axle seats 9, wherein the sprocket set 2 is provided with at least two. It is to smoothly transport the glass plate 6 on the production line to the sealing and welding room, and send the glass plate 6 out of the welding room after the sealing and welding is completed. In this embodiment, there are three spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com