Caliper detection apparatus

A detection device and caliper technology, which is applied to measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of the wear surface and degree of wear of the caliper being difficult to detect, the measuring surface of the caliper being easy to wear, and difficult to measure, etc. , to improve the efficiency of inspection and maintenance, simple structure, and rapid maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

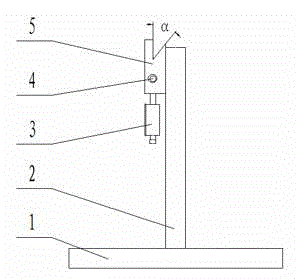

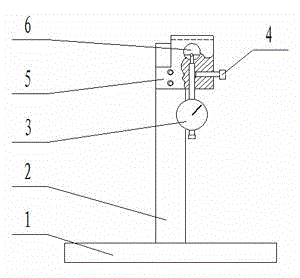

[0009] Such as figure 1 , figure 2 The caliper detection device shown mainly includes a base 1, a column 2 is arranged in the center of the base 1, a measuring block 5 is fixed on the column 2 by screws, and a dial indicator or a dial indicator 3 is fastened to the measuring block by screws 4 5 on. The measuring block 5 is provided with an angle α measuring groove, and its angle α measuring groove is consistent with the angle measuring surface of the caliper.

[0010] The measuring block 5 is provided with an observation hole 6 .

[0011] When working: First, check whether the parts on the caliper detection device are fastened intact, make a standard part according to the angle dimension of the measuring caliper, calibrate the display value of the dial indicator or dial indicator 3, and adjust the angle of the caliper after calibration. The measuring place is put into the angle α measuring groove of the measuring block 5, and moves linearly in the angle α measuring groove,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com