Battery explosion-proof structure and battery comprising battery explosion-proof structure

An explosion-proof structure and battery technology, applied in secondary batteries, structural parts, battery pack parts and other directions, can solve the problems of poor safety, small explosion-proof membrane area, easy accidental damage to the explosion-proof membrane, etc., to improve production efficiency and simple battery structure. , Strengthen the effect of explosion-proof safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

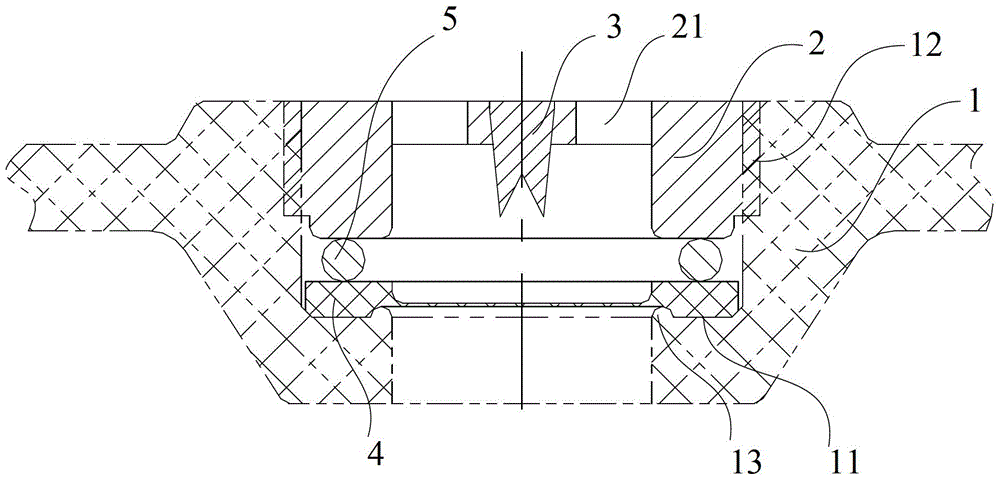

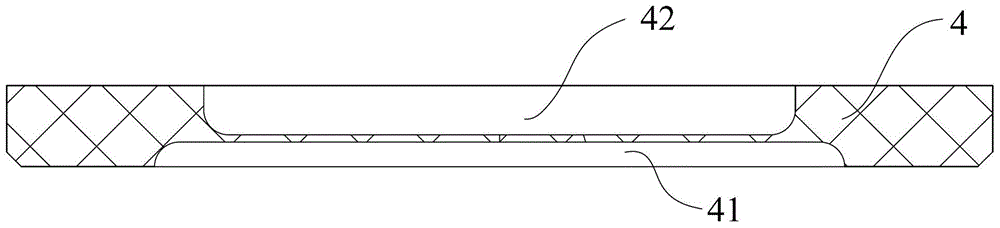

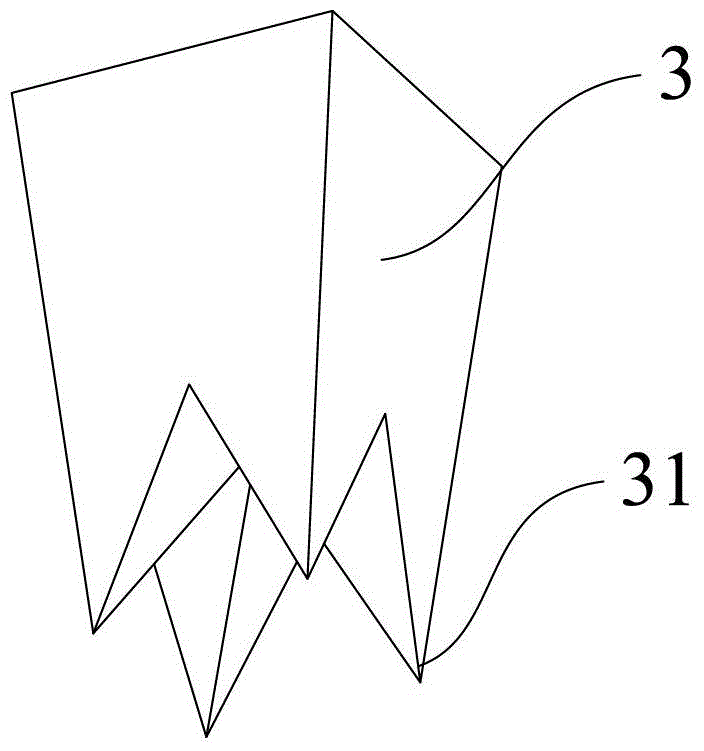

[0027] Such as Figure 1-4 As shown, the battery explosion-proof structure of the present invention includes a battery case cover 1 , a compression nut 2 , an explosion-proof pin 3 and an explosion-proof membrane 4 . The battery case cover 1 is provided with a counterbore, and the counterbore has a stepped surface 11 , and the explosion-proof membrane 4 and the compression nut 2 are sequentially arranged on the stepped surface 11 . The inner wall of the counterbore is provided with an internal thread 12 cooperating with the compression nut 2, and the compression nut 2 is fixedly connected with the internal thread 12 on the inner wall of the counterbore through the external thread. The top surface of the compression nut 2 is provided with four exhaust holes 21 for exhausting gas when the gas in the battery b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com