Thermocompression-free composite electrode for direct methanol fuel cell and preparation method thereof

A methanol fuel cell and composite electrode technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of complicated processing or preparation processes, and achieve the effects of improving battery performance, reducing resistance and contact resistance, and good management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

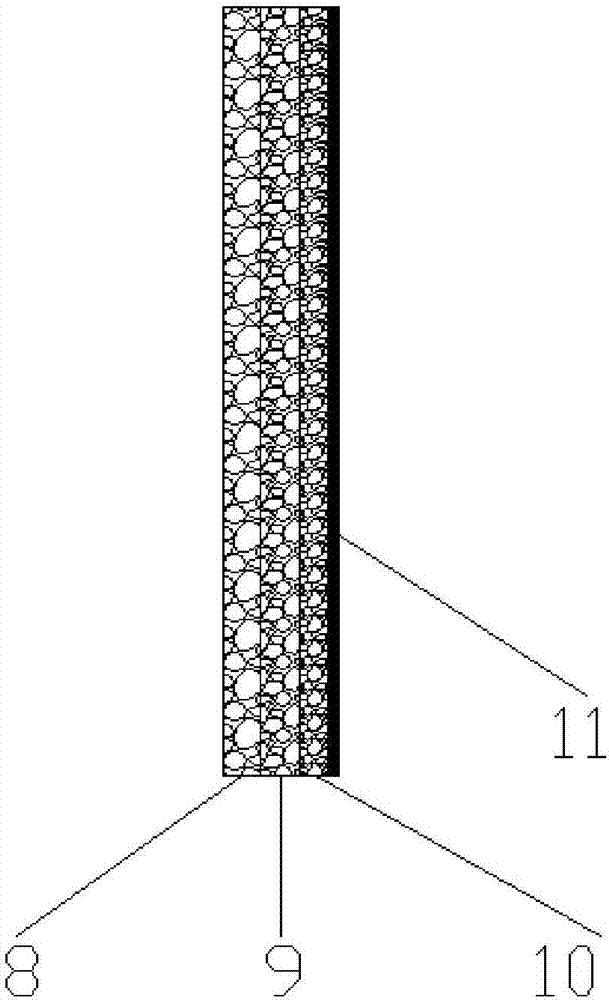

[0049] This embodiment is an integrated flow field diffusion layer with three copper sintered porous plates in the form of gradually changing porosity, and its cross-sectional schematic diagram is as follows figure 2 shown. Among them, the three copper sintered porous plates include porous plate 8, porous plate 9 and porous plate 10 in turn, and the porosity of the three sintered porous plates is 90%, 80% and 70% in turn, forming a porous plate with a thickness of 1 mm. Plate; the filling layer 11 is attached to the side of the perforated plate 10 and part of its internal space.

[0050] The material of the cathode filling layer is a mixture of conductive carbon black and polytetrafluoroethylene with a mass ratio of 5:1, and the material of the anode filling layer is a mixture of conductive carbon black and perfluorosulfonic acid with a mass ratio of 10:1;

[0051] The material of the catalytic layer is a mixture of catalyst and perfluorosulfonic acid with a mass ratio of 3:...

Embodiment 2

[0054] This embodiment is an integrated flow field diffusion layer with three copper sintered porous plates in the form of gradually changing porosity. Among them, the porosity of the three sintered porous plates is 85%, 75% and 65% in turn, forming a porous plate with a thickness of 1.5 mm. The filling layer is attached to the side of the porous plate with a porosity of 65% and part of its internal space. .

[0055] The material of the cathode filling layer is a mixture of conductive carbon black and polytetrafluoroethylene with a mass ratio of 10:1, and the material of the anode filling layer is a mixture of conductive carbon black and perfluorosulfonic acid with a mass ratio of 5:1;

[0056] The material of the catalytic layer is a mixture of catalyst and perfluorosulfonic acid with a mass ratio of 1:1, and the catalytic layer is attached to the surface of the filling layer, thereby forming a heat-free and press-free composite electrode for direct methanol fuel cells.

[0...

Embodiment 3

[0059] This embodiment is an integrated flow field diffusion layer with two copper sintered porous plates in the form of gradually changing porosity. The porosity of the three sintered porous plates is 80%, 70% and 60% in turn, forming a porous plate with a thickness of 2 mm. The filling layer is attached to the side and part of the internal space of the porous plate with a porosity of 60%.

[0060] The material of the cathode filling layer is a mixture of conductive carbon black and polytetrafluoroethylene with a mass ratio of 20:1, and the material of the anode filling layer is a mixture of conductive carbon black and perfluorosulfonic acid with a mass ratio of 1:1;

[0061] The material of the catalytic layer is a mixture of catalyst and perfluorosulfonic acid with a mass ratio of 5:1, and the catalytic layer is attached to the surface of the filling layer, thereby forming a heat-free press composite electrode for direct methanol fuel cells.

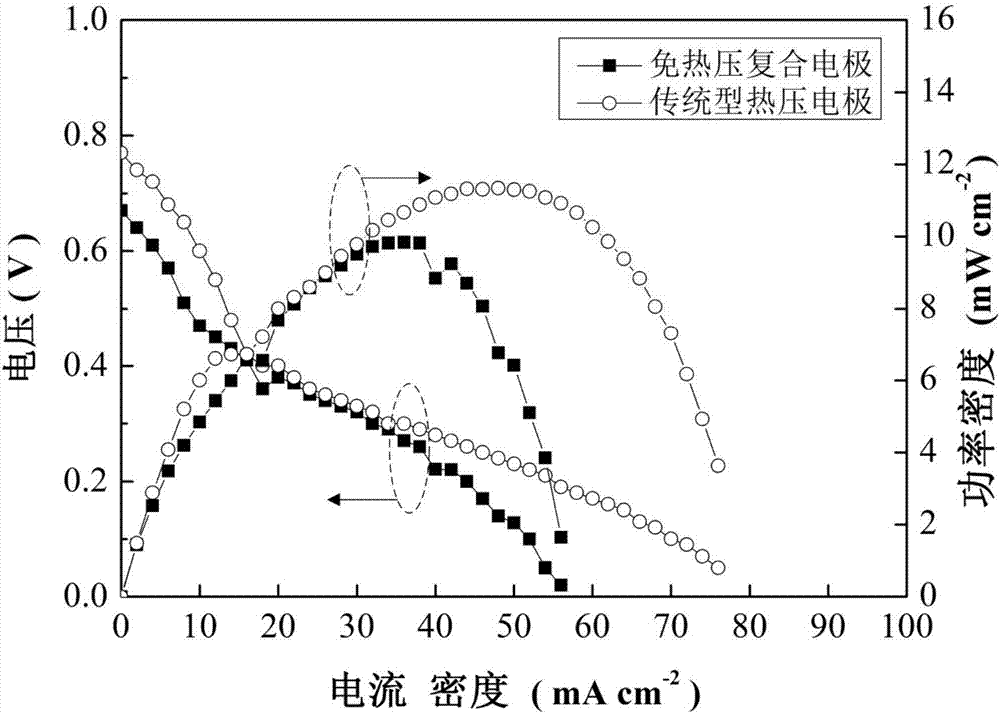

[0062] The heat-free composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com