A kind of preparation method of electrode material, battery and electrode material

A technology of electrode material and electrode active material, which is applied in the field of battery materials, can solve the problems that the ion diffusion rate cannot keep up, affect the charge and discharge rate, and the thickness of the electrode should not be too thick, so as to achieve easy mass production, low manufacturing cost, The effect of omitting the diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] First, prepare Na 1.3 Fe[Fe(CN) 6] A low-density cathode material as a cathode active material.

[0040] S1: first mix 20 g of acrylamide, 0.1 g of methylenebisacrylamide, and 1 g of sodium 2-acrylamide-2-methylpropanesulfonate, and dissolve them in 75 ml of water.

[0041] S2: Add 120 grams of Na to the aqueous solution obtained in S1 1.3 Fe[Fe(CN) 6 ], 30 grams of conductive carbon black, 10 grams of foamable plastic microspheres (expanded microspheres), then add 0.1 gram of sodium bisulfite, 0.1 gram of sodium persulfate, and stir at room temperature to make a slurry.

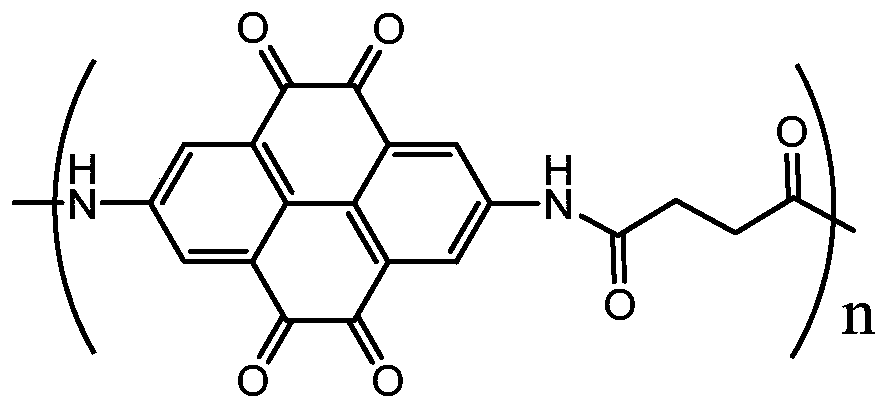

[0042] S3: Place the slurry obtained in S2 in an environment of 35 degrees Celsius and continue to stir to initiate the polymerization reaction. Under the exothermic action of the polymerization reaction, the temperature of the system rises to 60 degrees Celsius, and the monomers in the system are polymerized into acrylamide / methylene Based bisacrylamide / 2-acrylamide-2-methylpropanesulfonate sodiu...

Embodiment 2

[0046] Preparation of NaTi 2 (PO 4 ) 3 Be the high-density negative electrode material of negative electrode active material, step and above-mentioned " prepare Na 1.3 Fe[Fe(CN) 6 ] As the positive electrode material of positive electrode active material " process is similar, just, in step S2, with 120 grams of Na 1.3 Fe[Fe(CN) 6 ] replaced with 140 g NaTi 2 (PO4) 3 As a negative electrode active material, no expandable plastic particles are added in the preparation process, and no microwave heating step is required.

Embodiment 3

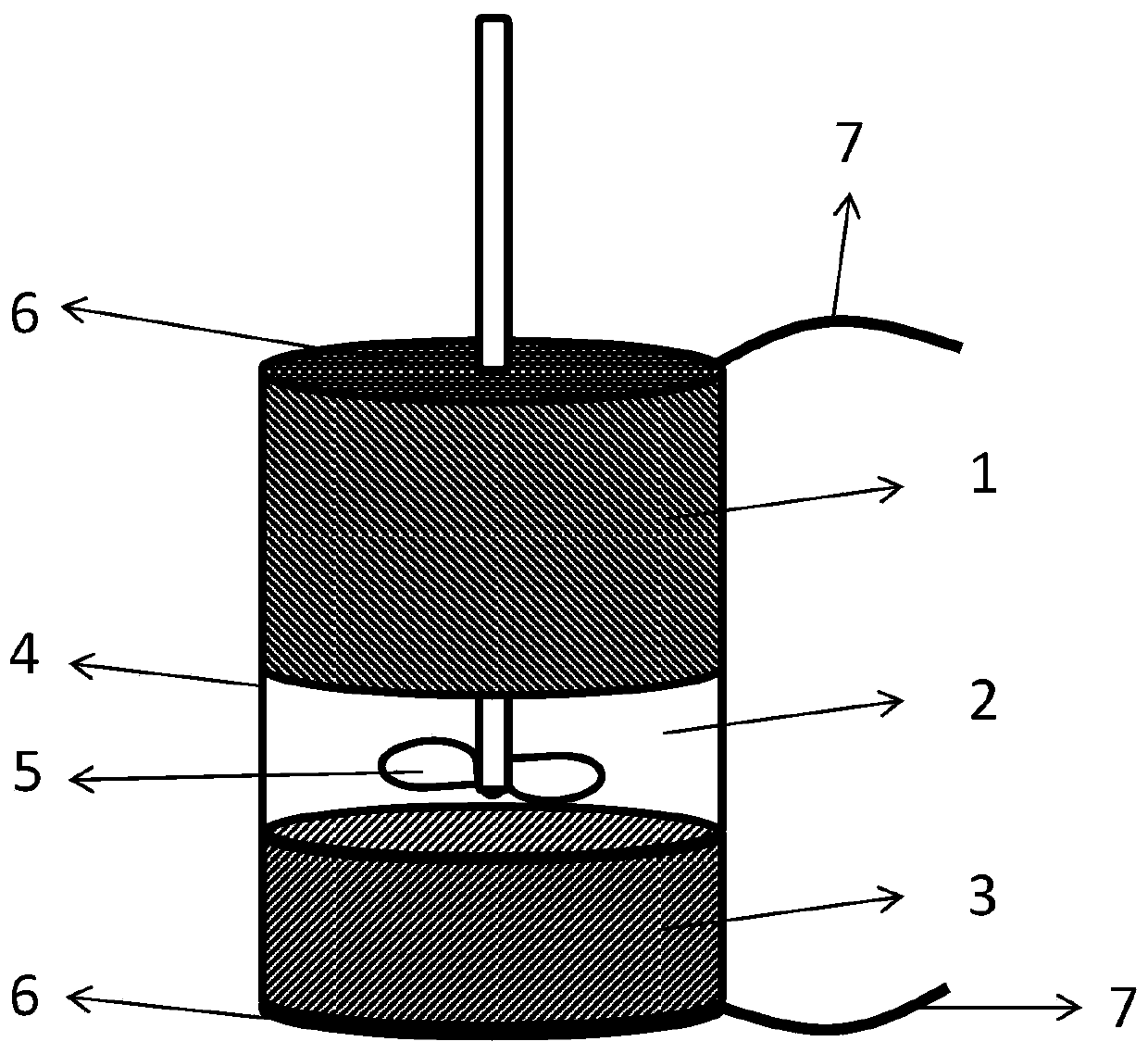

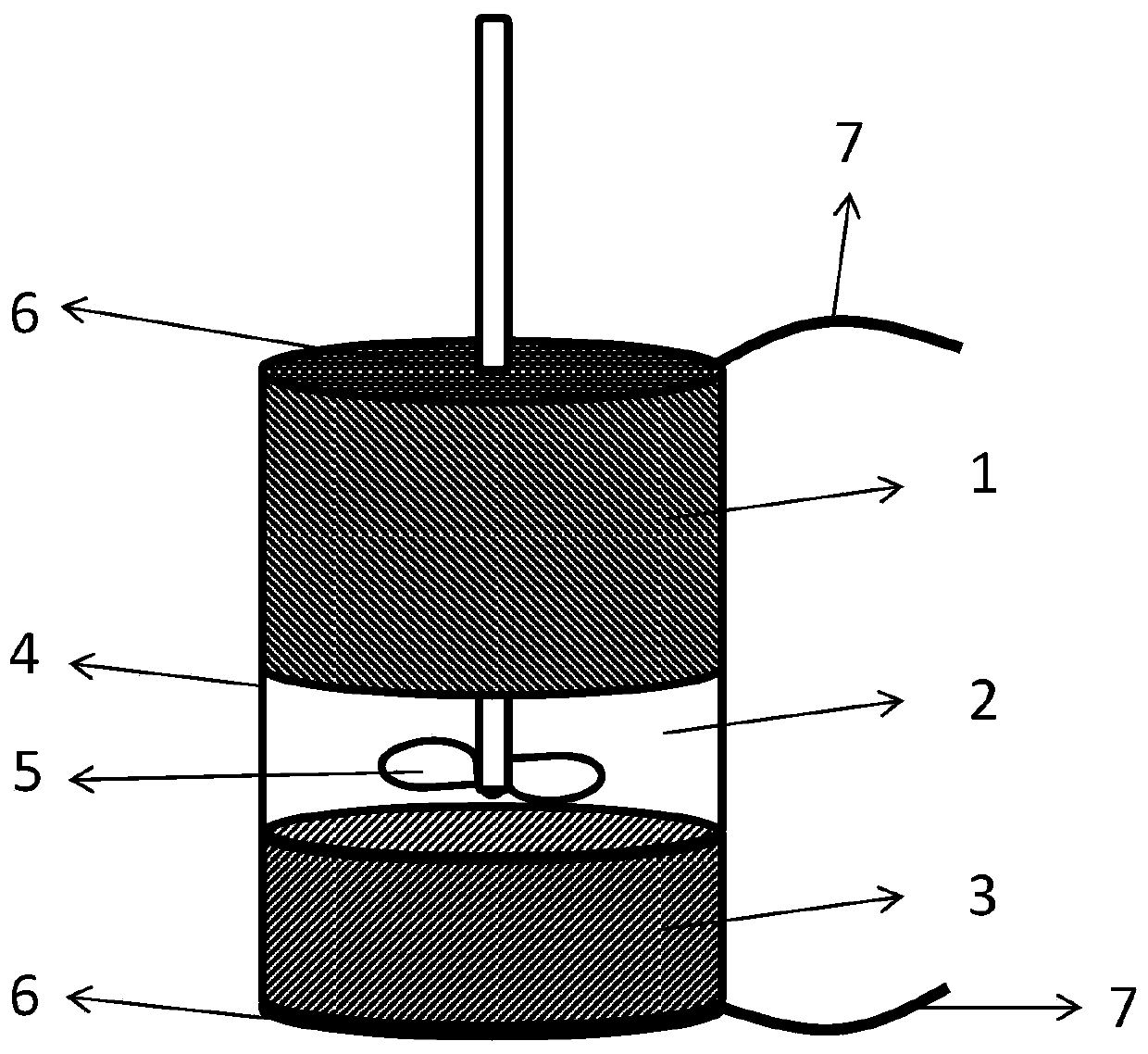

[0048] The positive electrode material prepared in Example 1, the negative electrode material prepared in Example 2, and 200 milliliters of 1 mole per liter of Na 2 SO 4 The aqueous solution (aqueous electrolyte) is all placed in a container 4 with a diameter of 8 cm and a height of 14 cm. The bottom of the container 4 is a stainless steel plate, the side wall is polypropylene plastic, the top is a stainless steel cover, and a stirring rod penetrates into the container through the hole in the top. Under the action of gravity, the positive electrode material 1, the aqueous electrolyte solution 2 and the negative electrode material 3 are automatically divided into three layers from top to bottom. The stainless steel cover on the top can be used as the stainless steel current collector 6 of the positive electrode, and the stainless steel plate at the bottom can be used as the stainless steel current collector 6 of the negative electrode. Positive and negative electrode current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com