Rotor position sensor

A technology of rotor position and sensor, applied in the direction of electromechanical devices, electrical components, structural connections, etc., to achieve the effect of saving structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

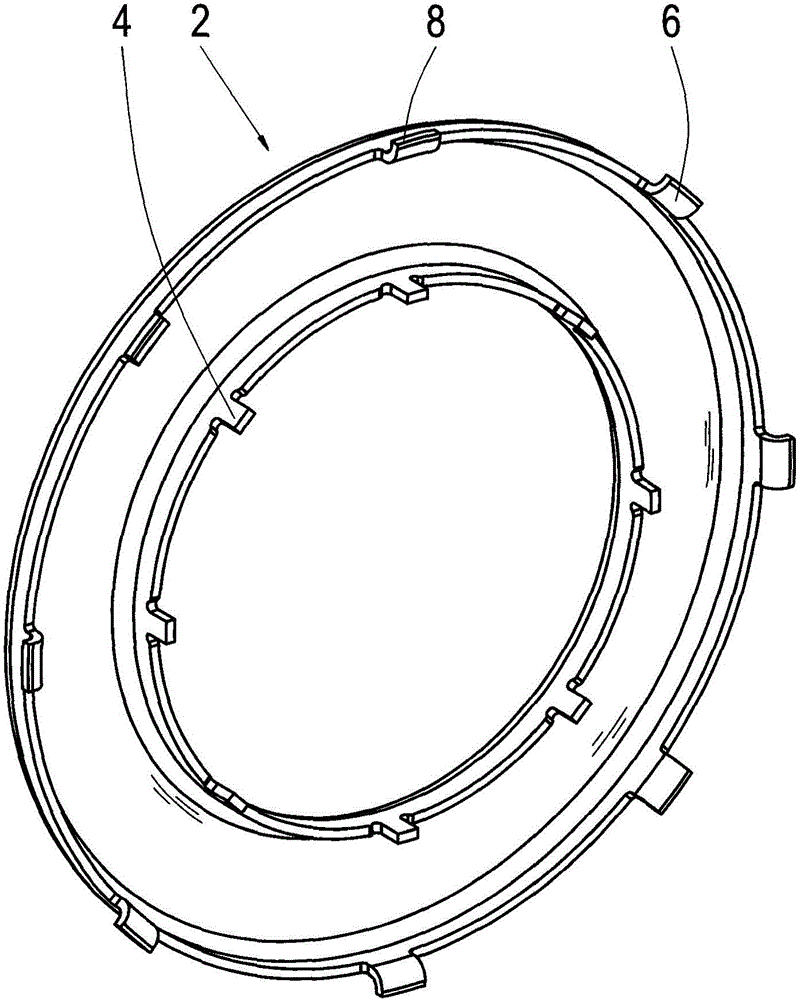

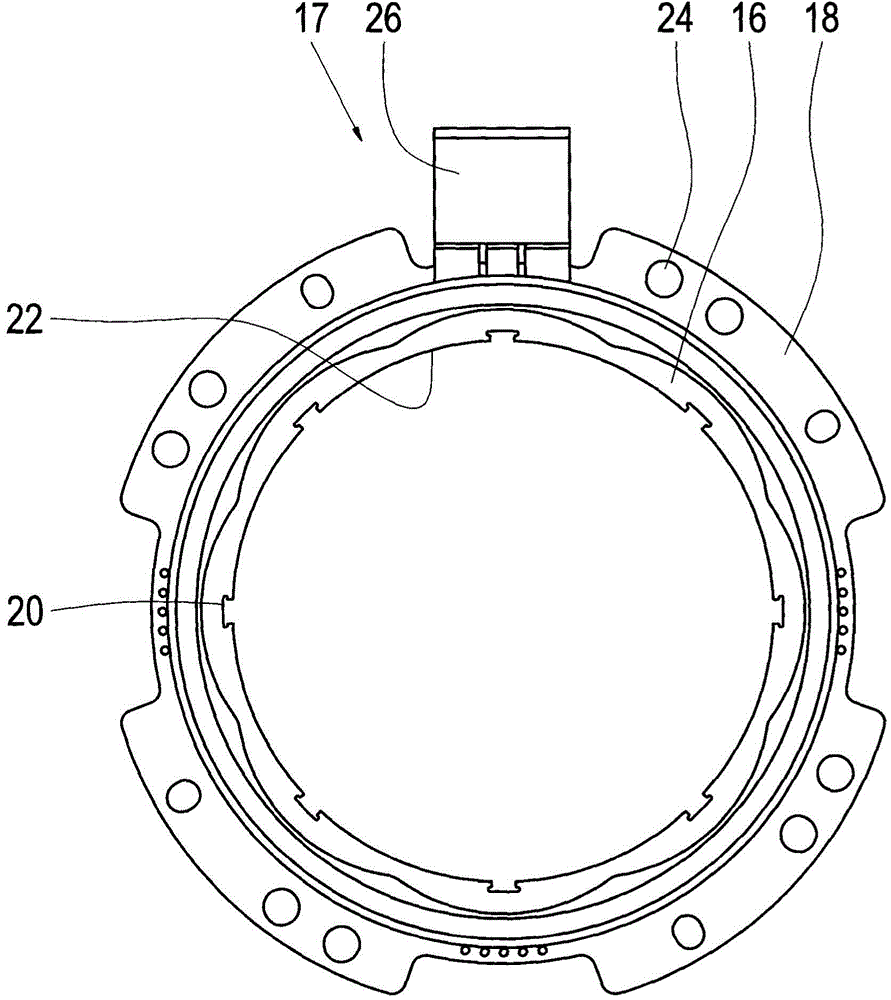

[0024] Figure 1 schematically in perspective view ( Figure 1a ) and in section view ( Figure 1b ) shows the rotor position sensor-rotor frame 2 according to the invention. as especially available from Figure 1a As can be seen in the figure, the rotor position sensor-rotor frame 2 according to the invention has substantially axially extending projections 4, 6, such as Figure 1a Arranged as shown on the inner periphery (projection 4 ) of the rotor position sensor rotor carrier 2 and on its outer periphery (projection 6 ). In this case, the projection 6 also has, at the outer circumference, a projection 8 extending radially outward.

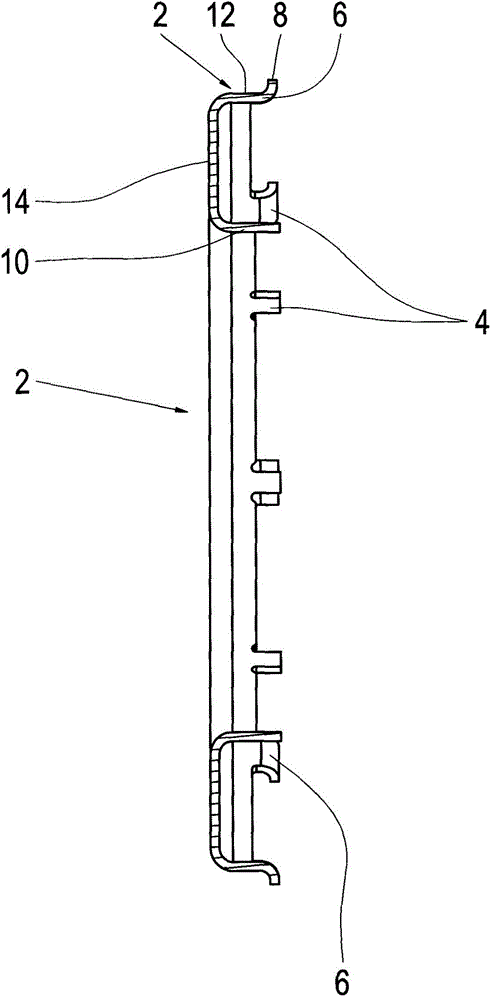

[0025] Furthermore, especially Figure 1b The sectional illustration in FIG. 2 shows that the rotor position sensor rotor frame is C-shaped and has a first side arm 10 and a second side arm 12 , which are connected to each other by radially extending connecting elements 14 . In addition, if available from Figure 1b As can be seen in , the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com