Ion exchange resin pulverization device and ion exchange resin pulverization method

An ion exchange resin, pulverizing device technology, applied in chemical instruments and methods, mixers with rotary stirring devices, transportation and packaging, etc., can solve problems such as disadvantages, increased surface and space requirements, spherical resin mixing, etc. space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

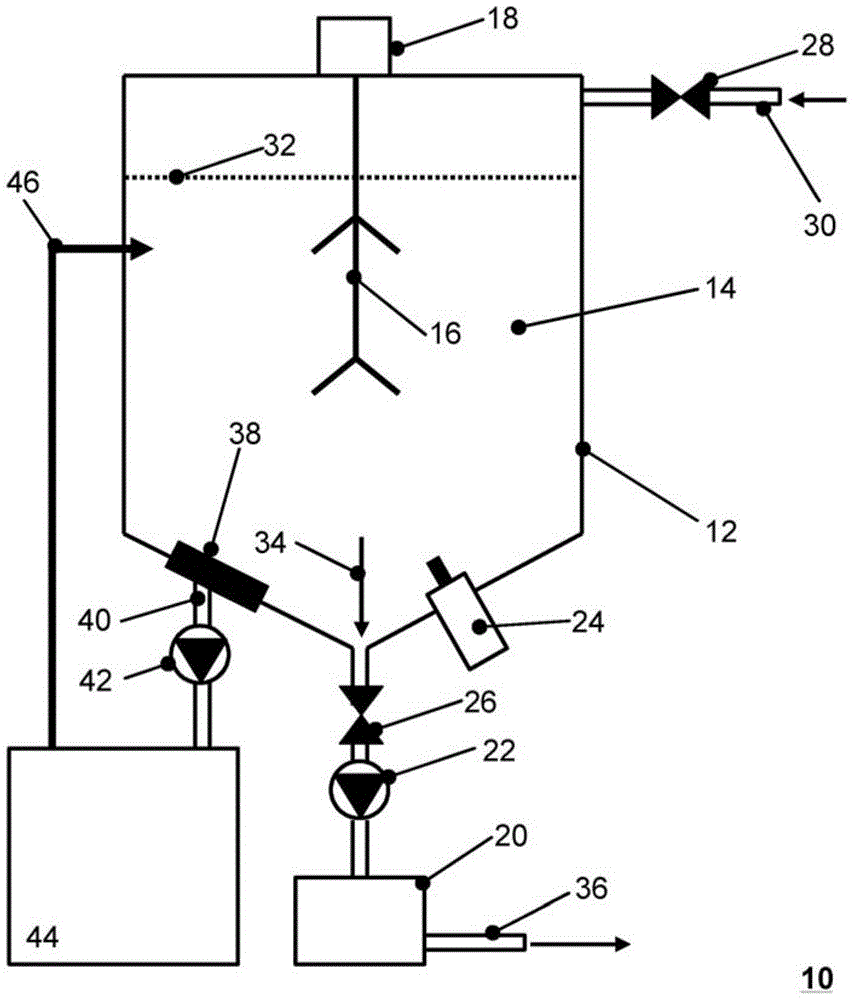

[0042] attached figure 1 A schematic diagram of an exemplary ion exchange resin pulverization apparatus 10 is shown. The jar 12 is filled with the ion exchange resin suspension 14 , wherein the level of filling is indicated by the line identified by the reference numeral 32 . The jar 12 is made of high quality steel and has a filling capacity of eg 800L or significantly more. The top area of the jar is implemented as a hollow cylinder, while the bottom area tapers into a funnel-like outlet. Of course, an embodiment without such tapering is also possible. An ion exchange resin suspension inlet 30 is provided in the region above the tank, which inlet can be closed by means of a second shut-off valve 28 . It is of course also possible to provide multiple inlet valves so that the final suspension is formed only in the tank 12 .

[0043] A stirring device 16 extends into the tank 12 from the upper middle, which is driven by a drive 18 on the outside. The stirring device 16 k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com