Full-automatic capsule strain machine

A strain machine and fully automatic technology, applied in horticulture, botany equipment and methods, plant cultivation, etc., can solve the problems of low production efficiency and high inoculation failure rate, and achieve simple and compact structure, high degree of automation, and not easy to pollute Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

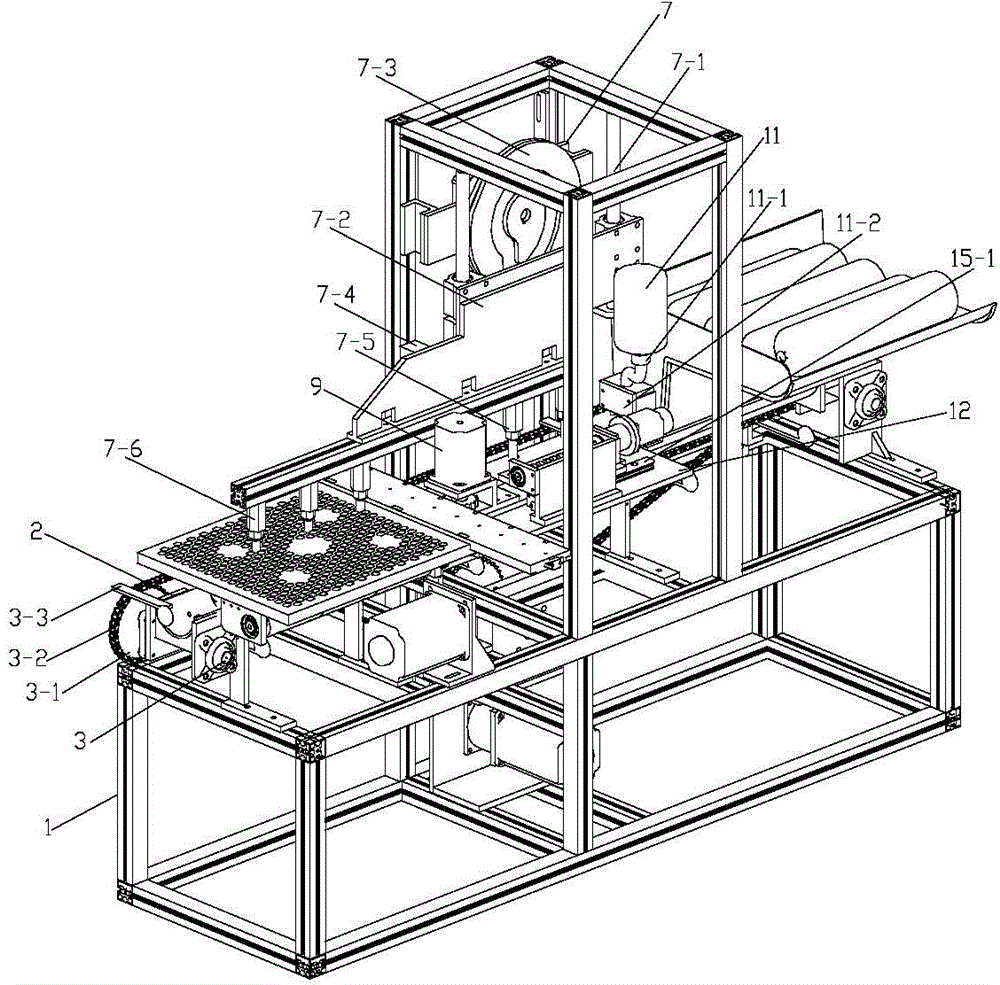

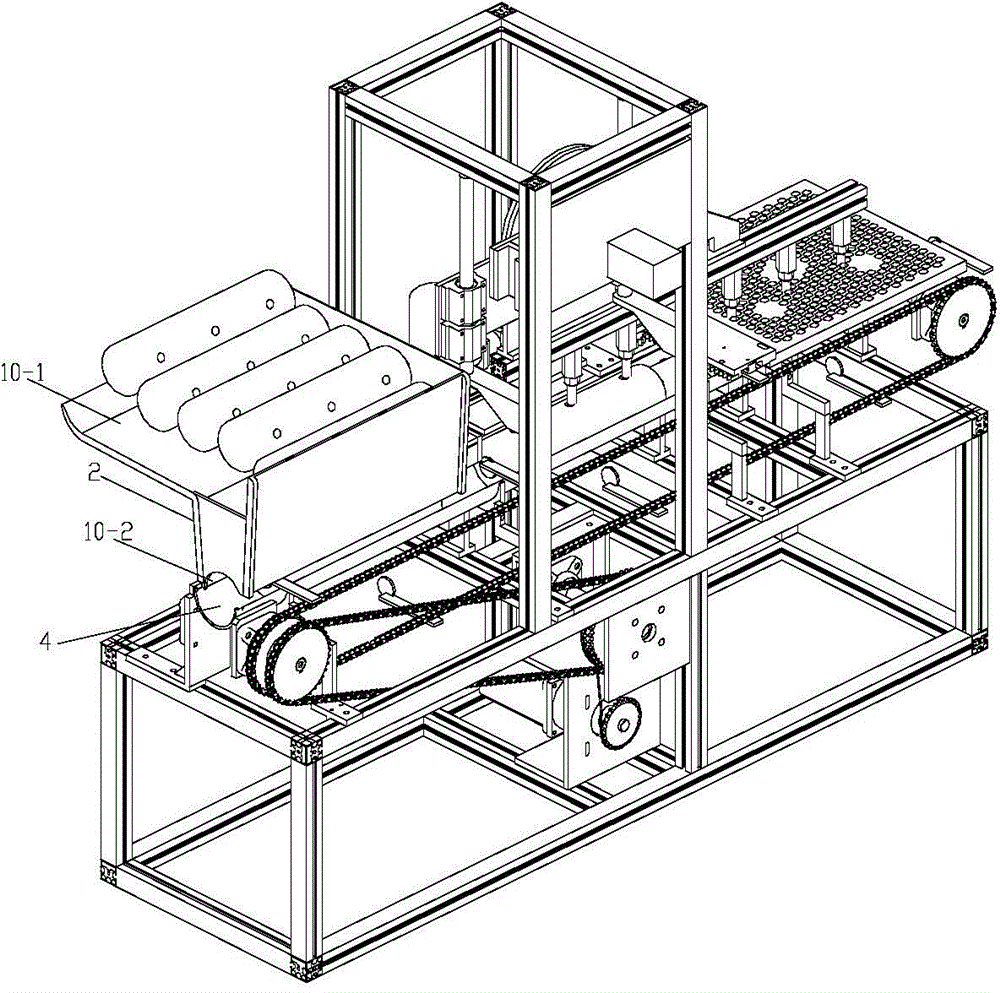

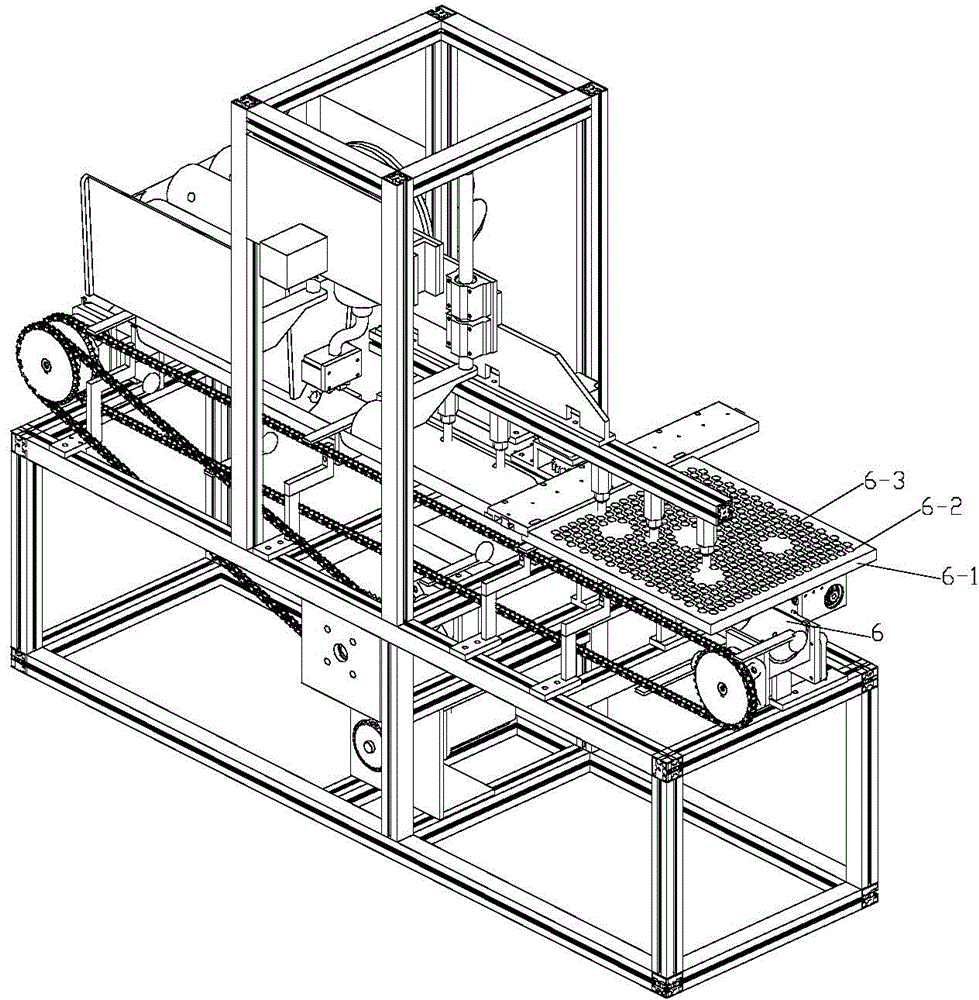

[0023] Refer to attached Figure 1-6: This full-automatic capsule spawn machine includes a frame body 1, a feed track 2 is provided on the frame body 1, a delivery shaft 3 is installed at the front end and rear end of the delivery track 2, and a sprocket 3- 1. The sprocket 3-1 is connected with a chain 3-2 meshed with the sprocket 3-1, and the chain 3-2 is equipped with push plates 3-3 distributed on the chain 3-2 at intervals; the feeding track 2 is divided into Blanking fixed seat 4, punching fixed seat 5 and strain fixed seat 6, the top of punching fixed seat 5 is provided with elevating mechanism 7, and elevating mechanism 7 comprises guide rod 7-1, movable frame 7-2 and driving device 7- 3. The movable frame 7-2 is socketed on the guide rod 7-1, the frame body 1 is provided with a support plate 7-4 for fixing the guide rod 7-1, and the movable frame 7-2 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com