A kind of chassis type long fiber filter and its construction method

A construction method and long-fiber technology, which is applied in the field of sewage treatment and water supply, can solve the problems of inability to guarantee the uniformity of the filter material and damage the uniformity of the filter material, and achieve high backwash recovery rate, good effluent quality, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

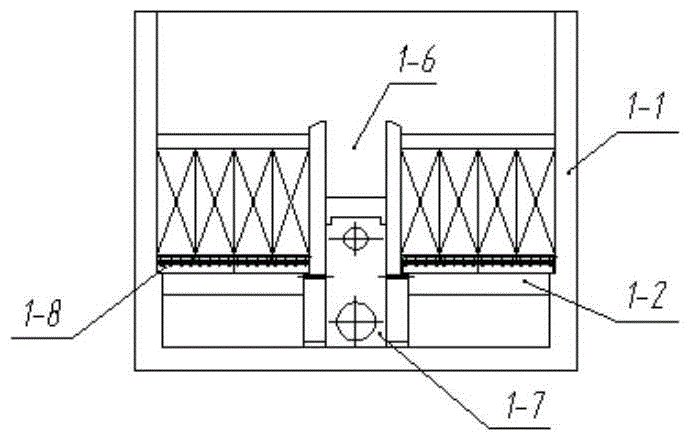

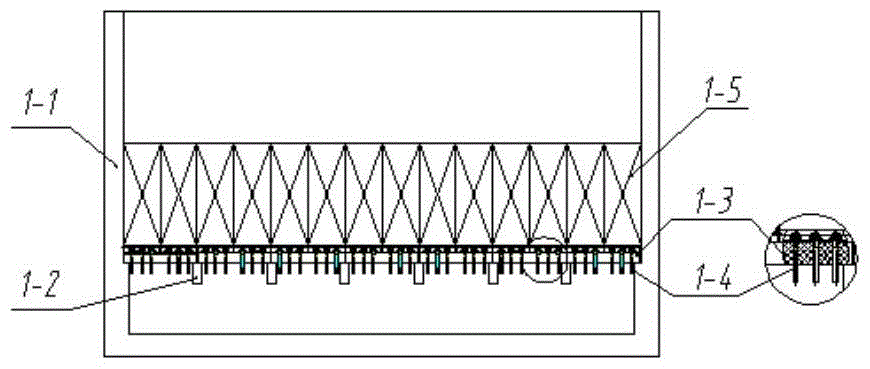

[0028]A chassis-type long fiber filter tank, comprising: a long fiber filter assembly 1-5, the filter tank also includes a tank body 1-1, a bottom beam 1-2 is arranged in the tank body 1-1, and a bottom beam 1-2 is arranged on the bottom beam 1-2 is fixed with a mesh base frame 1-8, and a filter plate assembly 1-3 and a long fiber filter assembly 1-5 are arranged in each grid of the mesh bottom frame 1-8, and the long fiber filter assembly 1 -5 is located above the filter plate assembly 1-3, and the filter plate assembly 1-3 and the long fiber filter assembly 1-5 together form a water body filtration unit, the present embodiment can further take the following technical measures:

[0029] The filter plate assembly 1-3 includes a filter plate and a filter cap 1-4 arranged on the filter plate, and an annular limiting plate 3-3 is arranged in each grid of the grid base frame 1-8, and the annular The lower surface of the limiting plate 3-3 is in contact with the upper surface of th...

Embodiment 2

[0031] A construction method of an underframe type long fiber filter,

[0032] Step 1 Build the pool body 1-1, and then build the installation and maintenance passage connected to the pool body 1-1 (that is, the passage for construction personnel or maintenance personnel to enter and exit), and set a sealed door between the pool body 1-1 and the installation and maintenance passage , build a horizontal bottom beam 1-2 in the pool body 1-1, and then connect the mesh bottom frame 1-8 to the bottom beam 1-2,

[0033] Step 2 Install and fasten the long fiber filter assembly 1-5 on each grid of the grid base frame 1-8 respectively, and connect the bottom of the long fiber filter assembly 1-5 to the bottom of the grid base frame 1-8. grid-style chassis 1-8 are installed and connected together,

[0034] Step 3: Install and fasten the filter plate assembly 1-3 on each grid of the grid base frame 1-8, and install the leveled filter plate assembly 1-3 from the bottom of the grid base f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com