Novel flat bag type dust remover

A dust collector and flat bag technology, applied in the field of new flat bag type dust collector, can solve the problems of high energy consumption, large resistance, low dust removal efficiency, etc., and achieve the effect of meeting layout requirements, long service life, and thorough dust removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

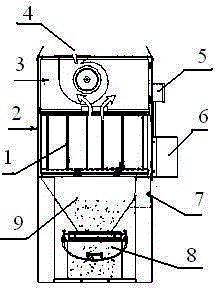

[0012] Referring to the accompanying drawings, the present invention includes a dust collecting device, a polluted gas ram chamber 2 and a blower chamber 3, and the dust collecting device includes an air inlet 7 and an ash hopper 9, between the air inlet 7 and the ash hopper 9 There is an air intake baffle between them, which can make the larger dust particles fall into the dust collection bucket 8 first, which reduces the wear on the flat cloth bag and prolongs the service life of the flat cloth bag; the polluted gas punching chamber 2 is located in the dust collection bucket Above the device, a vibrating motor 6 is provided on the side of the polluted gas stamping chamber 2, and a flat cloth bag and a metal insert 1 are arranged inside the polluted gas stamping chamber 2. The flat cloth bag is airtightly communicated with the ash hopper 9, and the flat cloth bag Supported by the metal flashboard 1, an isolation spring is arranged on the metal flashboard 1. The fan chamber 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com