A solvent recovery system for a printing press

A recycling system technology for printing machines, applied in industrial buildings, dispersed particle separation, steam condensation, etc., can solve the problems of solvents volatile atmosphere, high cost, polluting solvent usage, etc., to avoid solvent pollution of the air and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

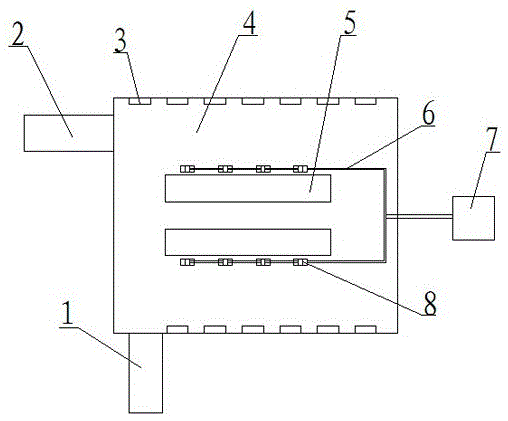

[0018] As shown in the figure, the specific implementation method is as follows:

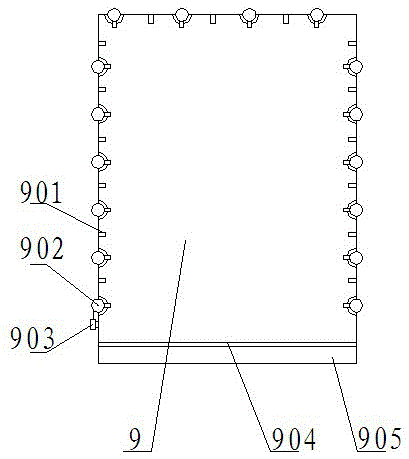

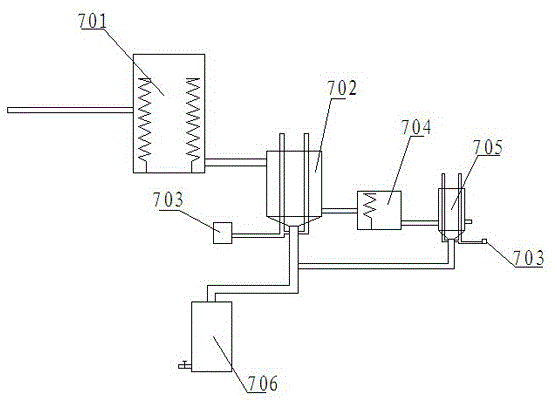

[0019] A solvent recovery system for a printing machine, comprising a sealed factory building and a printing machine arranged in the sealed factory building, the sealed factory building 4 is provided with an inlet 2 and an outlet 1, and the inlet 2 and the outlet 1 of the sealed factory building 4 are respectively arranged There is a dust removal device 9, and a plurality of vents 3 and lighting holes are provided on the surrounding walls of the sealed factory building 4 to ensure the air flow and lighting effects in the sealed factory building 4. The sealed factory building is also equipped with a dust collector for collecting the dust around the printing machine. The solvent collecting device 8 that has volatilized the solvent air and the solvent processing device 7 that is arranged outside the factory building for processing the air collected by the solvent collecting device 8 and purifying th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com