Compound kettle type reactor

A tank reactor and compound technology, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical processes, etc., can solve uneven stirring, inability to universally apply multiple reaction solutions, Bringing in impurities and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

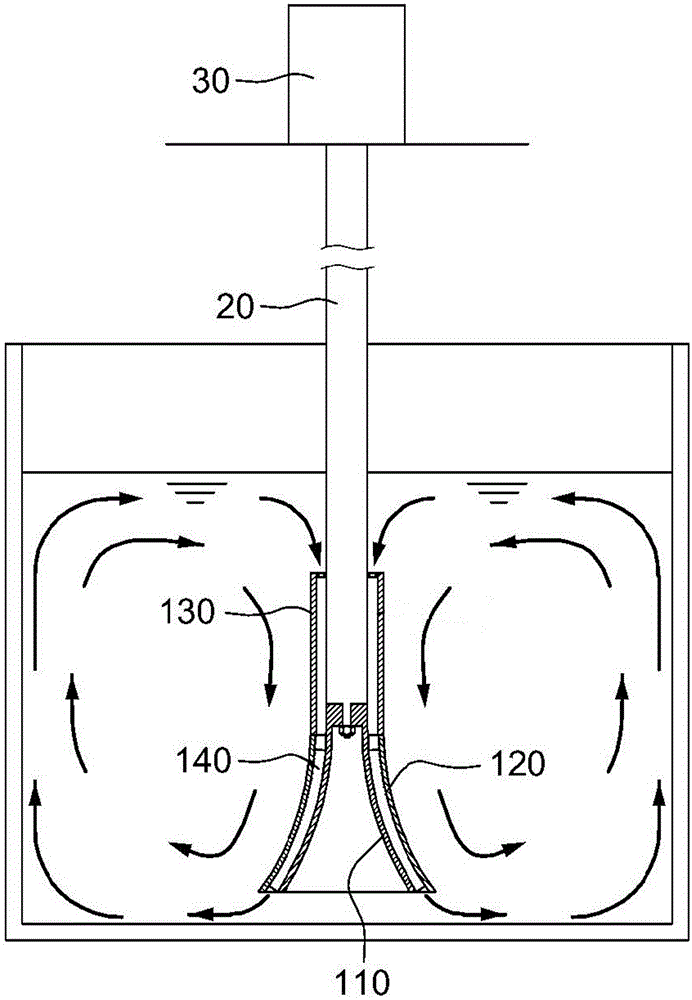

[0025] like figure 1 As shown, the compound tank reactor includes a tank body, an inner tank arranged in the tank body, and a stirrer arranged in the inner tank. The agitator includes a stirring paddle and a stirring shaft 20 connected to each other. It is driven by the motor 30 provided on the kettle body.

[0026] According to conventional requirements, the reaction solution should be injected into the inner tank first, and the liquid level of the reaction solution is required to cover at least the stirring paddle.

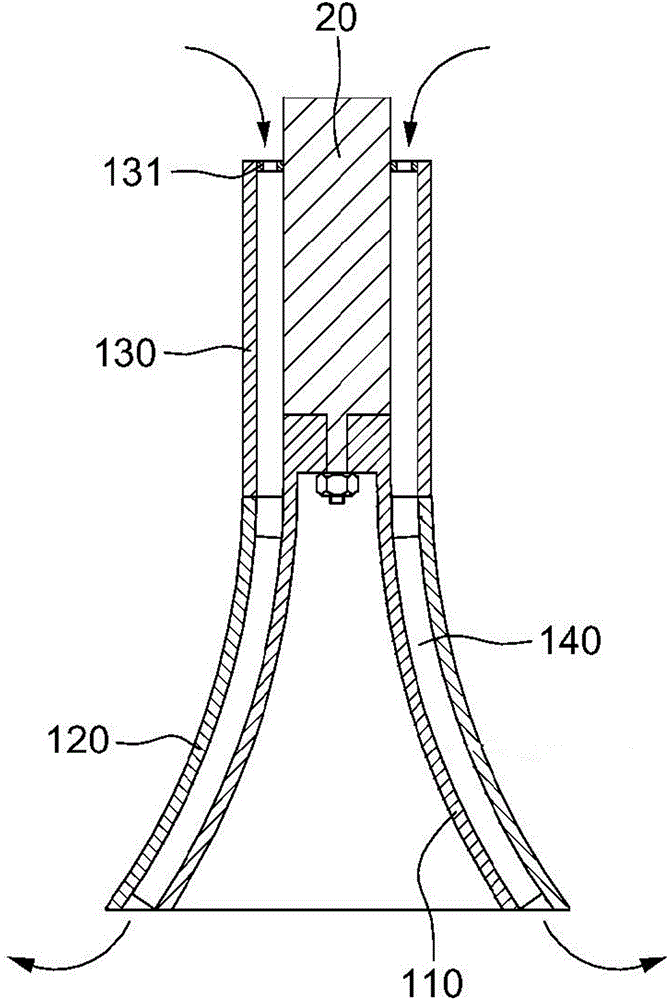

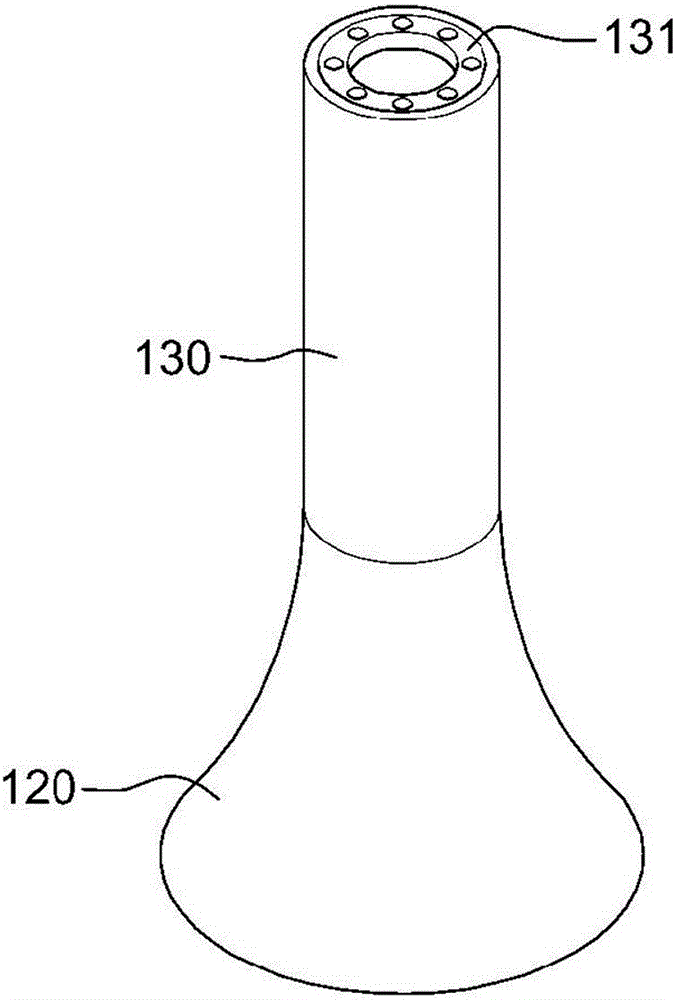

[0027] After the liquid level reaches a certain height, the motor 30 is started, and the motor 30 drives the stirring shaft 20 to rotate. like figure 2 As shown, the stirring paddle includes an outer sleeve and an inner sleeve 110, the outer sleeve includes a hollow straight cylinder 130 and an outer stirring cylinder 120 connected in sequence, and the upper port of the outer stirring cylinder 120 and the lower port of the hollow straight cylinder 130 are int...

Embodiment 2

[0031] like Figure 5 As shown, the outer surface of the outer stirring drum 120 is provided with a group of through holes 122 which pass into the gap. The outer surface of the outer mixing drum 120 is also provided with a helical outer rotating blade 150 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com