Clean bench capable of monitoring cleanliness in real time

A real-time monitoring and cleanliness technology, applied in the field of biosafety purification, can solve problems such as safety risks, loss of clean workbench function, and inability to guarantee filter integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

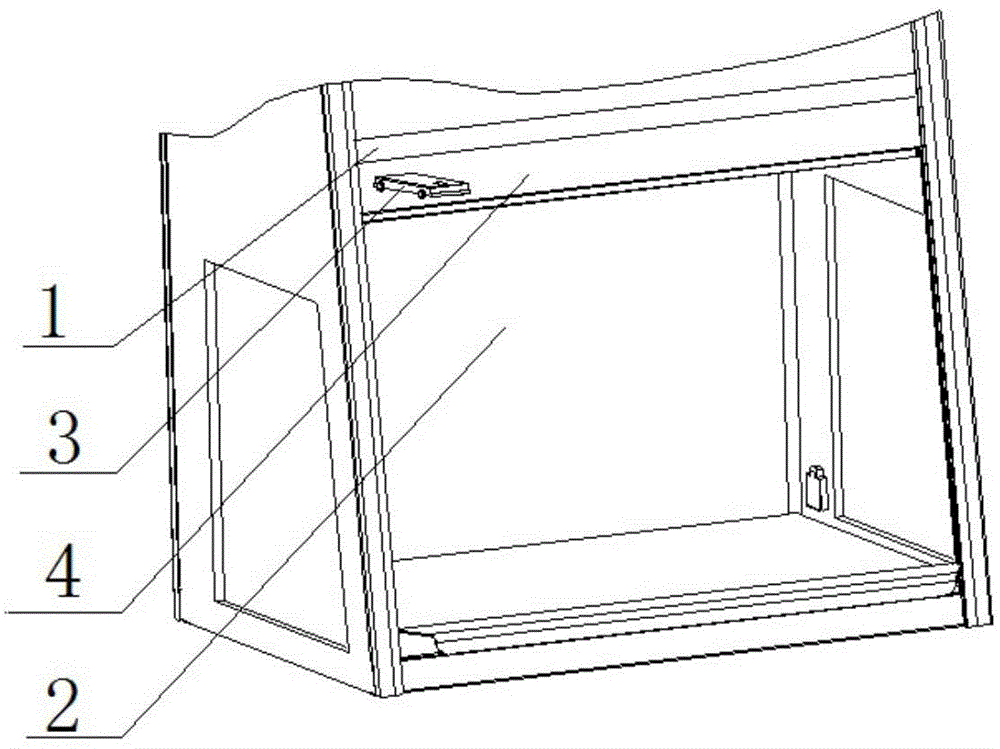

[0014] The clean workbench for real-time monitoring of cleanliness of the present invention will be further described in detail below in conjunction with the accompanying drawings.

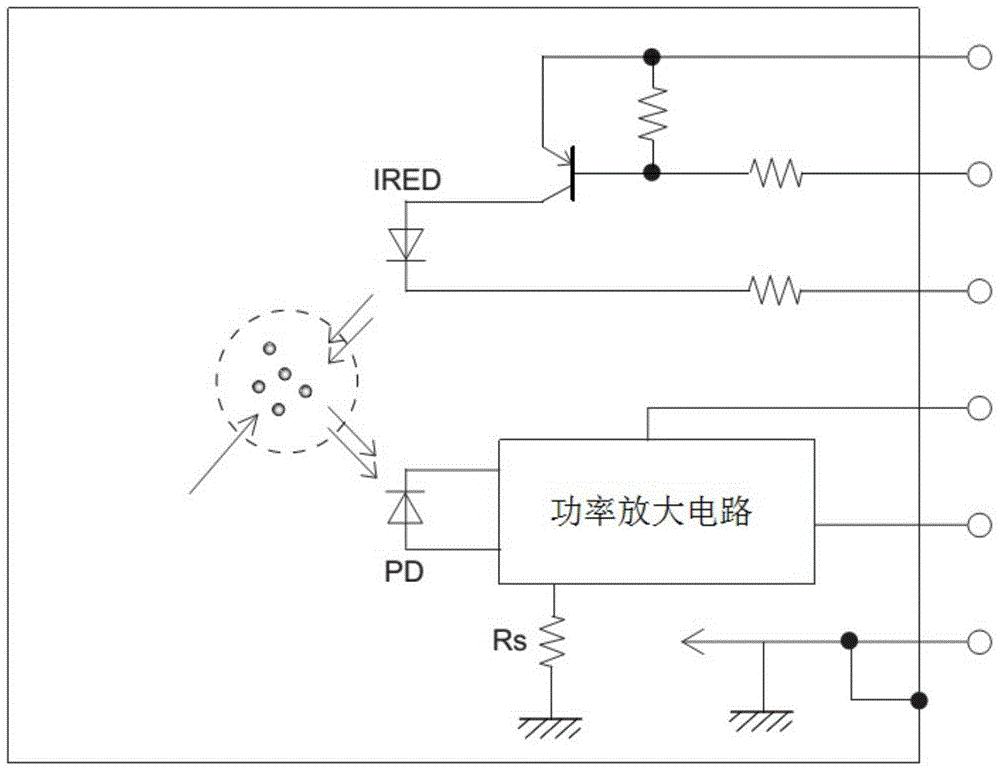

[0015] The working principle of the cleanliness detection structure is developed based on the principle of light scattering. Particles and molecules will produce light scattering phenomenon under the irradiation of light, and at the same time, absorb part of the energy of the irradiated light. When a beam of parallel monochromatic light is incident on the measured particle field, it will be affected by scattering and absorption around the particle, and the light intensity will be attenuated. In this way, the relative attenuation rate of the incident light passing through the concentration field to be measured can be obtained. The size of the relative attenuation rate can basically linearly reflect the relative concentration of dust in the field to be measured. The magnitude of the light intensity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com