Molding sand treatment process

A processing technology and molding sand technology, which is applied in the cleaning/processing machinery of casting mold materials, manufacturing tools, casting molding equipment, etc., and can solve problems such as unstable molding sand performance, multi-equipment investment, and high molding sand temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

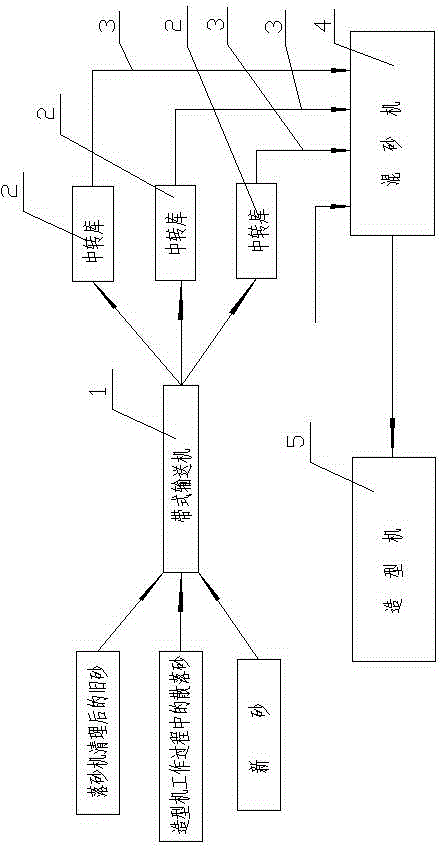

[0019] Such as figure 1 Shown, below in conjunction with accompanying drawing, technical process of the present invention is described in detail:

[0020] (1) Perform magnetic separation, humidification, and crushing on the old sand cleaned by the shakeout machine. When the crushed old sand is higher than 40°C, it needs to be cooled again to ensure that the temperature of the old sand is lower than 40°C.

[0021] The scattered sand in the working process of the molding machine is magnetically separated and crushed in sequence.

[0022] (2) Material preparation: 5kg of new sand, 80 kg of used sand after step (1), 15 kg of scattered sand after treatment in step (1), 0.5 kg of bentonite, and 3 kg of water.

[0023] (3) The old sand, scattered sand, and new sand are pre-mixed through the belt conveyor 1 at the same time, and then sent to the three transfer warehouses 2 in sequence.

[0024] (4) The pre-mixed old sand, scattered sand and new sand in the three transfer warehouses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com