Fixing mechanism for gear shaving

A technology for fixing mechanisms and gears, which is applied in the field of gear shaving processing, and can solve problems such as the influence of shaving quality, the inability to fix gears quickly and firmly, strong; the other side is an obtuse angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

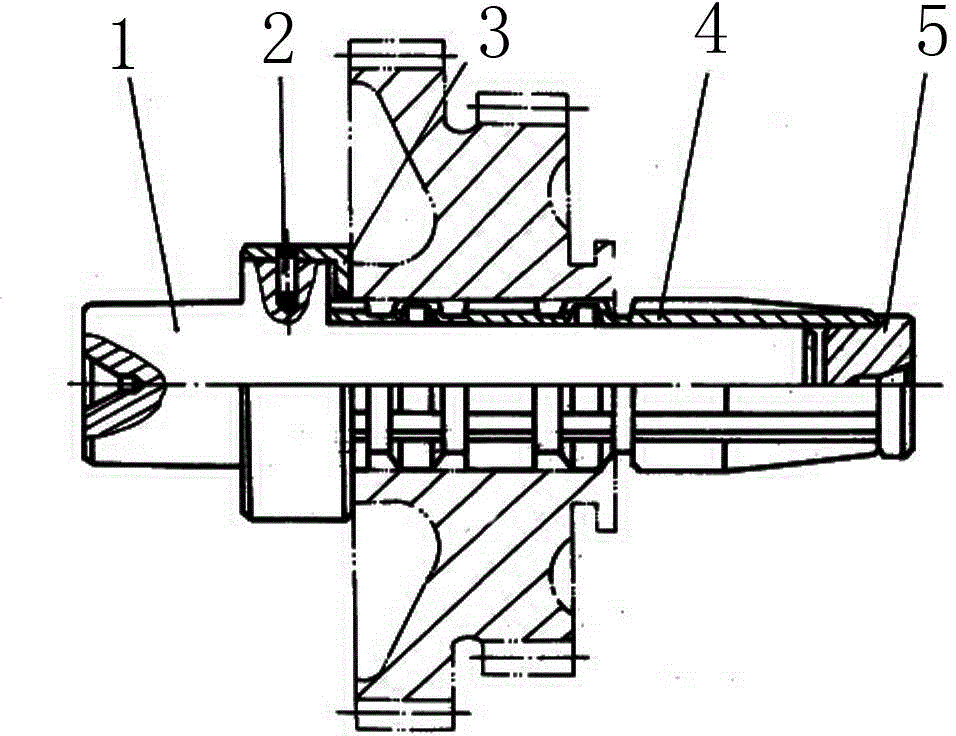

[0014] Embodiment one is basically as attached figure 1 As shown: the fixing mechanism for gear shaving includes a mandrel 1, a corrugated expansion sleeve 4, a gland 5 and a hydraulic cylinder arranged in sequence from left to right in the axial direction; the mandrel includes clamps arranged in sequence from left to right in the axial direction The clamping part, the shaft shoulder and the fixed part, wherein the clamping part and the machine tool are detachably connected, and the clamping part and the machine tool are fixed by a collet or a triangular chuck. The left end surface of the shaft clamping part is provided with a tapered Hole, the thimble can be pushed in the tapered inner hole to center the fixing mechanism, the shaft shoulder is covered with a positioning sleeve 3, the positioning sleeve includes the side wall sleeved on the shaft shoulder and the bottom plate sleeved outside the corrugated expansion sleeve, the side of the positioning sleeve The wall and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com