Single electrical signal excitation ultrasonic elliptic vibration metal welding device

An elliptical vibration and metal welding technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems that restrict the application and promotion of ultrasonic elliptical vibration transducers, the complex structure of ultrasonic vibration systems and control systems, and insufficient working performance. Stability and other issues, to achieve the effect of simple structure, large amplitude and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

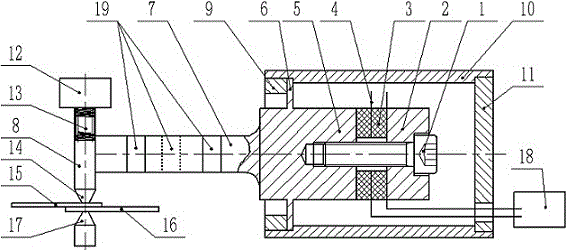

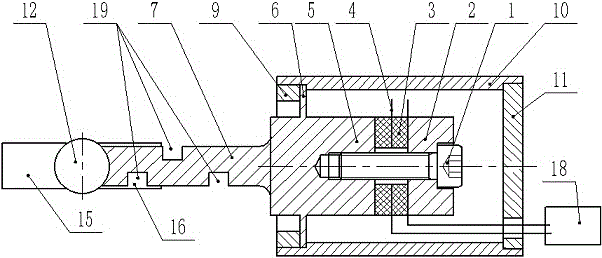

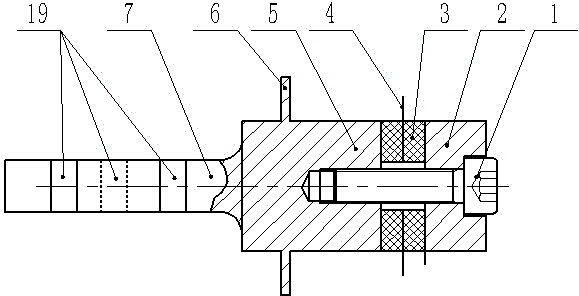

[0022] combine figure 1 , 2 , 3 and 4, a single electric signal excitation ultrasonic elliptical vibration metal welding device, including a pressure device 12, an ultrasonic vibration isolation device 13, a housing unit, an ultrasonic vibration transducer placed in the housing unit, an elliptical The vibration mode converter 7, the vibration head 8 arranged at the front end of the elliptical vibration mode converter 7, the upper acoustic pole 14, the lower acoustic pole 17 and the ultrasonic power supply 18 arranged below the vibration head 8; the ultrasonic vibration isolation device 13 is arranged on Between the pressure device 12 and the vibration head 8, it is used to isolate the influence of the pressure device 12 on the ultrasonic vibration system such as the vibration head 8; the upper acoustic pole 14 is arranged under the vibration head 8 by welding or screw connection, and the lower acoustic pole 17 It is arranged below the workpiece to be welded and coaxially oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com