Locating device for pipe fitting welding

A positioning device and pipe fitting welding technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficulty in ensuring concentricity, reducing welding efficiency, and affecting production quality, so as to ensure concentricity and improve production efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below through specific examples, but not in order to limit the present invention, all within the spirit and principle of the present invention, any modification, equivalent replacement, improvement etc. all should be included within the scope of protection of the present invention .

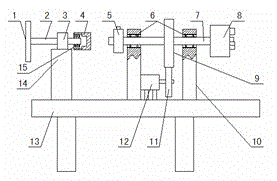

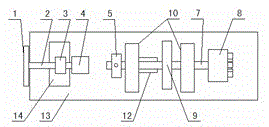

[0014] Such as figure 1 , figure 2 As shown, the pipe fitting welding positioning device includes a workbench 13 and a rotating shaft 7. A positioning bracket 14 and a support frame 10 are sequentially arranged on the workbench 13 from left to right. The rotating shaft 7 is horizontally installed on the support frame 10 through a bearing 6. The workpiece chuck 5 is installed on the left end of the rotating shaft 7, and the three-jaw chuck 8 is installed on its right end. The corresponding workpiece chuck 5 is equipped with a workpiece positioning mechanism on the positioning bracket 14. The workpiece positioning mechanism includes a screw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com