Conduit multifunctional honing device assembly

A multi-functional, honing technology that can be used in other manufacturing equipment/tools, metal processing machinery parts, maintenance and safety accessories, etc. It can solve the problems of long turnaround time between sequences, waste of resources, high product failure rate, and reduce labor costs. Control, reduce waste of resources, and solve the effect of inter-sequence turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

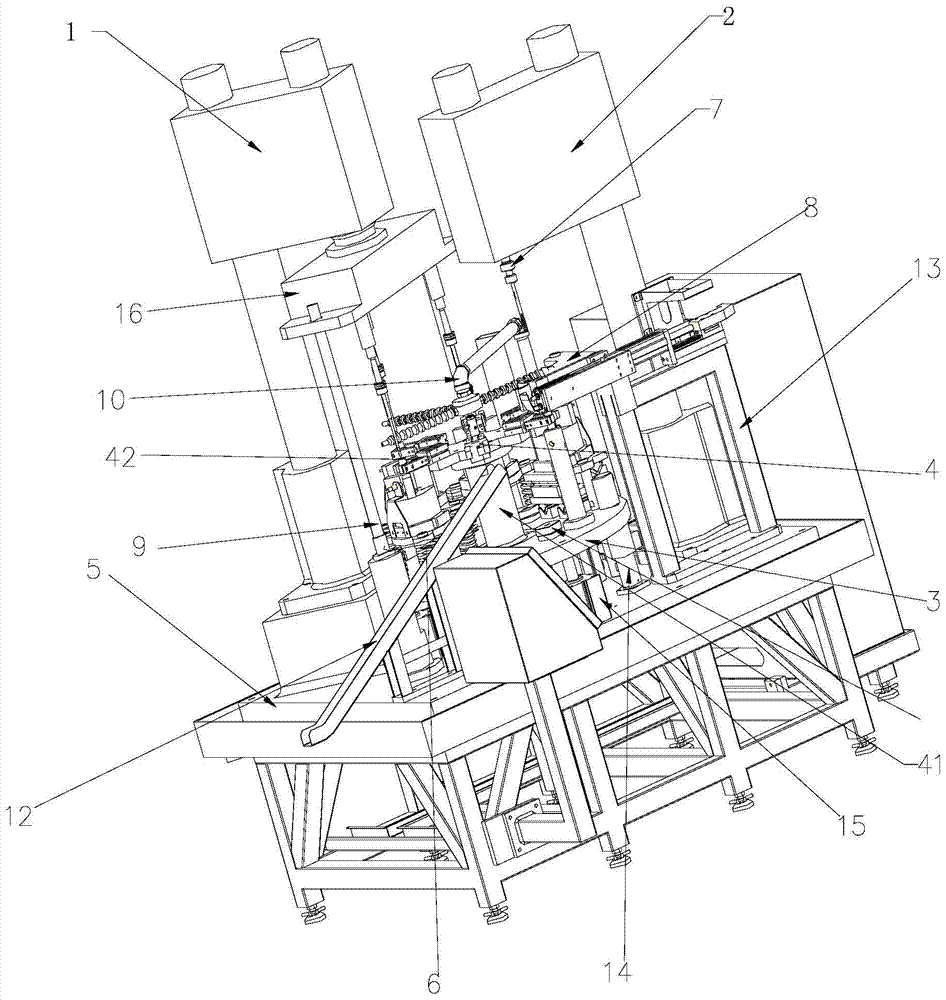

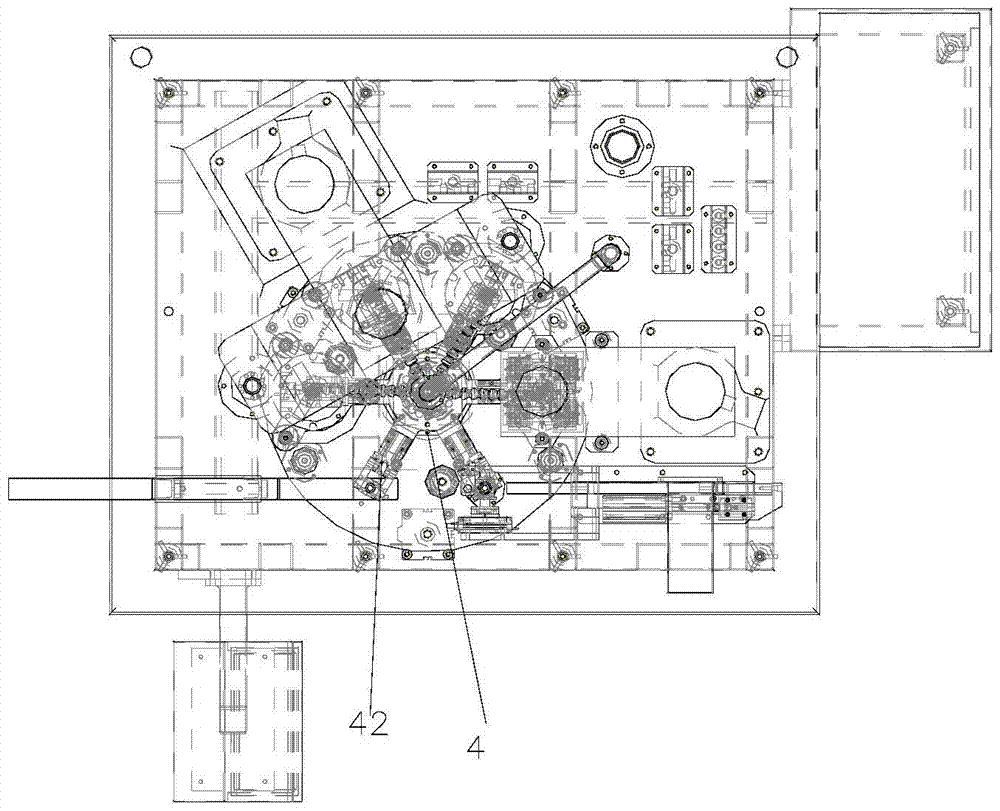

[0016] figure 1 for figure 1 It is a schematic diagram of the three-dimensional structure of the present invention, figure 2 It is a top view of the catheter multifunctional honing device assembly of the present invention, as shown in the figure: the catheter multifunctional honing device assembly of the present embodiment includes a lead screw type tapping power head 1 and a hydraulic drilling power head 2 and A floating workbench 3 that can move up and down. The workbench 3 is provided with a turntable 4 driven by a driving mechanism to clamp and fix the workpiece and rotate along the circumference of the workbench 3; the floating workbench 3 moves upward and drives the turntable 4 Move up to a certain position to fix the tapping process. After the tapping is completed, the floating worktable 3 moves down, so that the tap of the tapping power head 1 exits the workpiece, and then the worktable 3 moves upward, and the turntable 4 rotates to the drilling power head. 2. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com