Automatic sample loading mechanical arm for three-dimensional space of tensile testing machine

A tensile testing machine and three-dimensional space technology, applied in the direction of manipulators, program-controlled manipulators, measuring devices, etc., can solve the problems of sample clamping deflection, extremely high requirements for operators, and unguaranteed repetition accuracy of sample tests. To achieve the effect of improving accuracy and ensuring repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

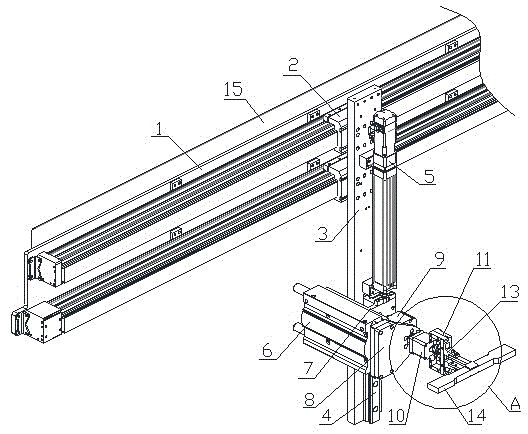

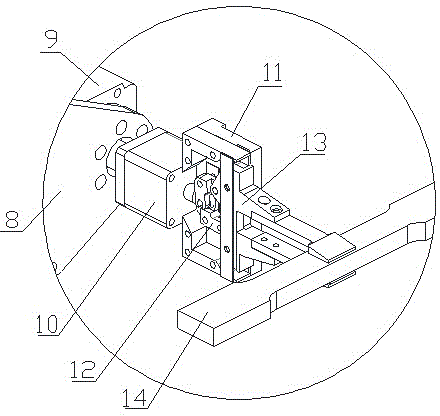

[0009] Such as figure 1 with figure 2 As shown, the three-dimensional space automatic sample loading manipulator of the tensile testing machine of the present invention includes a horizontal supporting plate 1, a vertical supporting plate 3, a lifting guide rail 4, a lateral moving electric cylinder 2, a lifting electric cylinder 5, a telescopic cylinder 6, and a lifting supporting plate 7 , mounting plate 8, rotating cylinder 9, clamping cylinder 10, clamping frame 11, pull rod 13 and clamp 13, described traverse electric cylinder 2 is arranged on described horizontal pallet 1, and described vertical pallet 3 It is vertically arranged on the slider of the traversing electric cylinder 2 and driven by the traversing electric cylinder 2 to move horizontally. The lifting electric cylinder 5 and the lifting guide rail 4 are respectively arranged on the vertical supporting plate 3. The lifting pallet 7 is set on the lifting guide rail 4 and driven by the lifting electric cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com