Automobile doorsill protective plate mounting structure

A door sill guard and installation structure technology, which is applied to the upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problem of insufficient core-pulling space for the sill guard, affecting the appearance quality of the sill guard, and insufficient installation strength of the sill plate, etc. problems, to achieve the effect of solving the problem of product installation strength, guaranteeing the appearance quality, and increasing the competitiveness of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

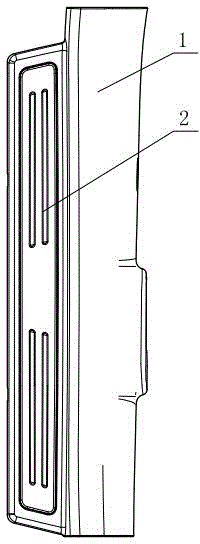

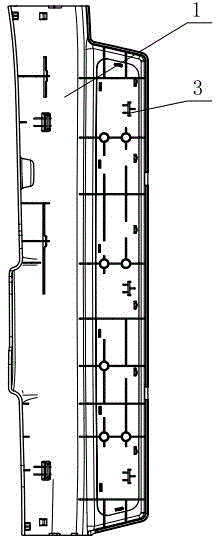

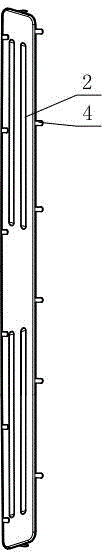

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the installation structure of the vehicle door sill guard in this embodiment includes a door sill guard body 1, a door sill guard trim 2 is welded on the front of the door sill guard body 1, and a plurality of decorations are arranged around the door sill guard trim 2. The strip welding fin 4 and the door sill guard plate decorative strip 2 are welded into a whole through the decorative strip welding fin 4 and the threshold guard plate body 1, and a plurality of buckle seats 3 are arranged at intervals on the reverse side of the door sill guard plate body 1, and the buckle seat Metal clip 5 is installed on 3, and metal clip 5 is connected with sheet metal.

[0022] Metal clip 5 becomes "Ω" shape structure.

[0023] In the actual installation process, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com