Safety tank ship used for transporting liquefied petroleum gas (LPG)

A liquefied petroleum gas, safety technology, applied in transportation and packaging, special-purpose ships, ships, etc., can solve problems such as potential safety hazards, and achieve the effect of preventing direct rigid collision and facilitating safe transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

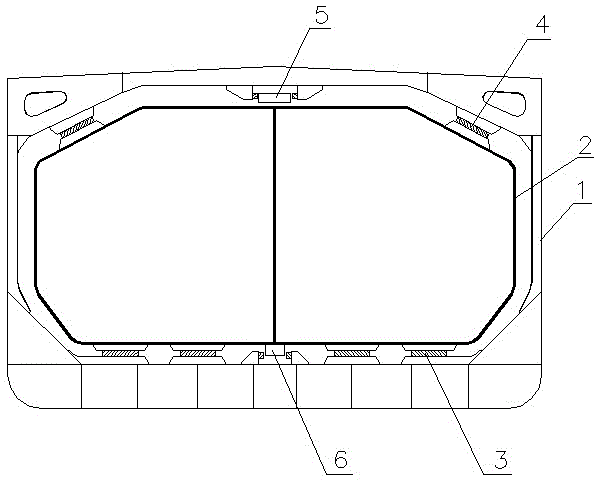

[0012] Such as figure 1 As shown, a prismatic cylindrical tank 2 is arranged along the cross section of the hull 1 in the hull 1, and the bottom, top and sides of the tank 2 are arc-shaped, thereby avoiding sharp corners.

[0013] Between the bottom of the tank body 2 and the hull 1, several bottom elastic supports 3 are uniformly distributed, and between the top of the tank body 2 and the hull 1, several anti-floating elastic supports 4 are evenly distributed.

[0014] Between the middle part of the top of the tank body 2 and the hull 1, a first anti-swing support 5 for limiting the lateral movement of the tank body on the hull is arranged. A second anti-swing support 6 for limiting the lateral movement of the tank body on the ship body is arranged between the middle part of the bottom of the tank body 2 and the hull 1 .

[0015] The tank body 2 can be installed on the load-bearing block above the steel load-bearing base, the load-bearing block is a thin plate type phenol re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com