Electric brake actuator integrating force sensor and ball screw

A technology of ball screw and force sensor, which is applied in the direction of brakes, brake transmission devices, vehicle components, etc., can solve the problems of low transmission efficiency, short service life, large structure volume, etc., and achieve improved measurement accuracy, small deformation, and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

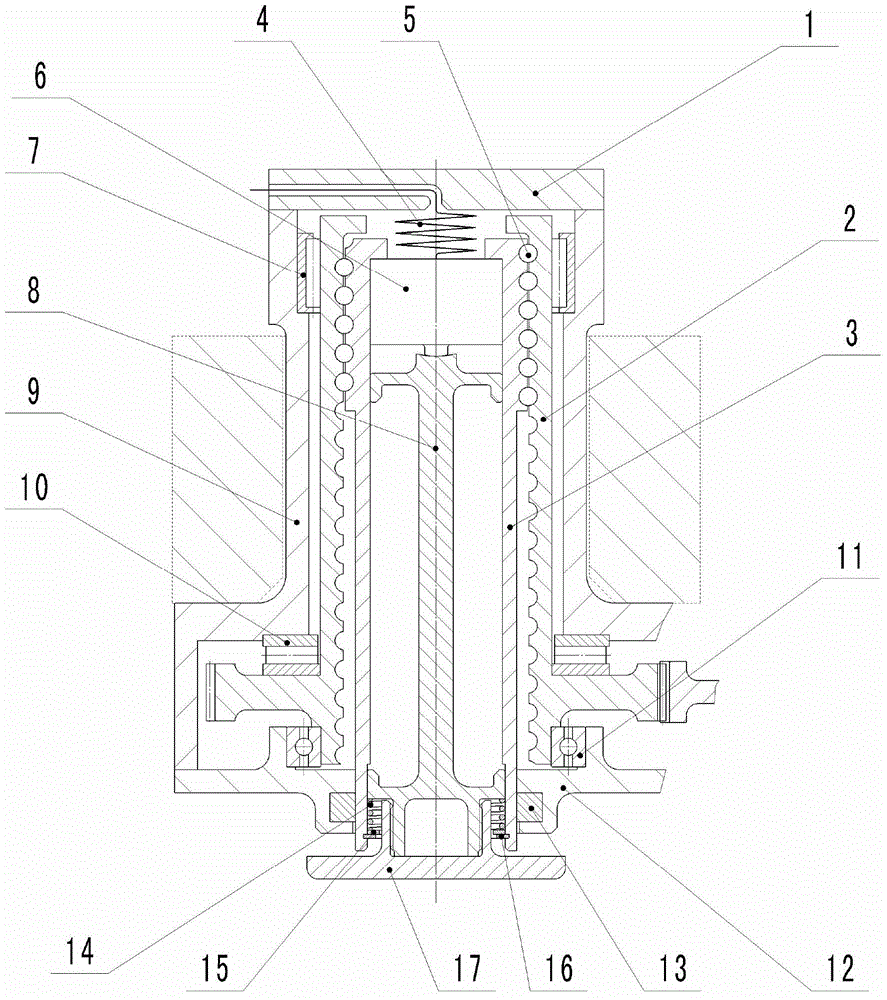

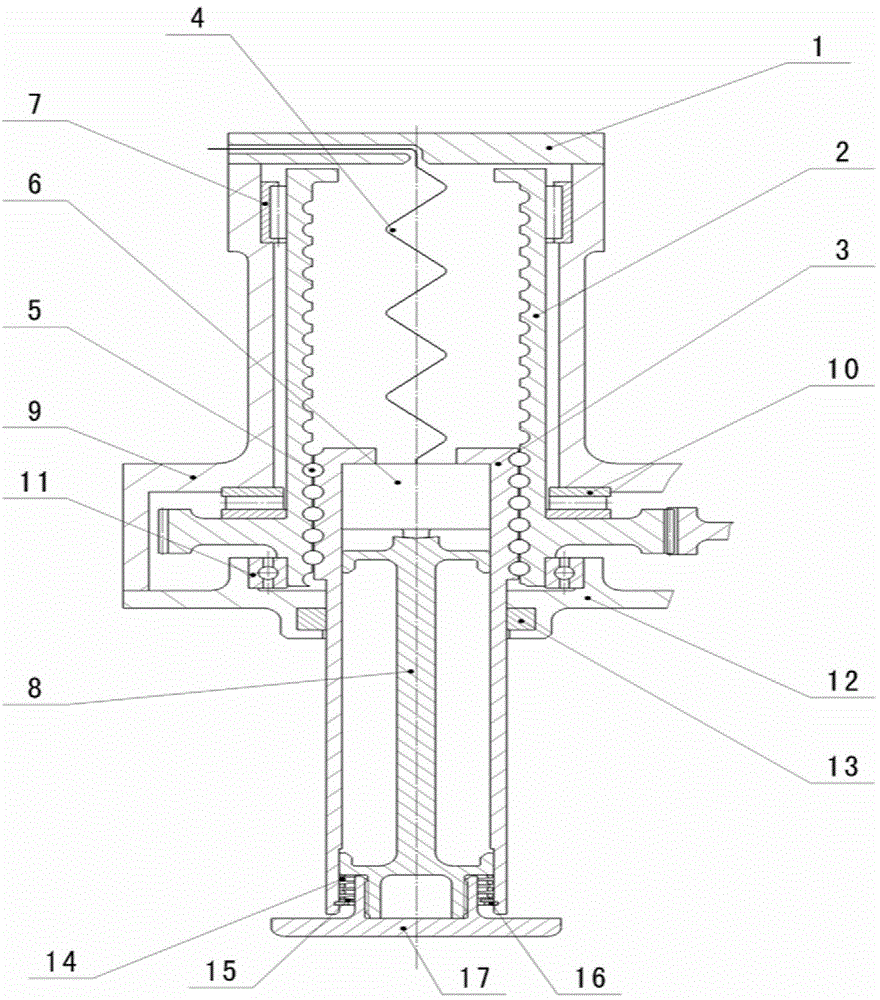

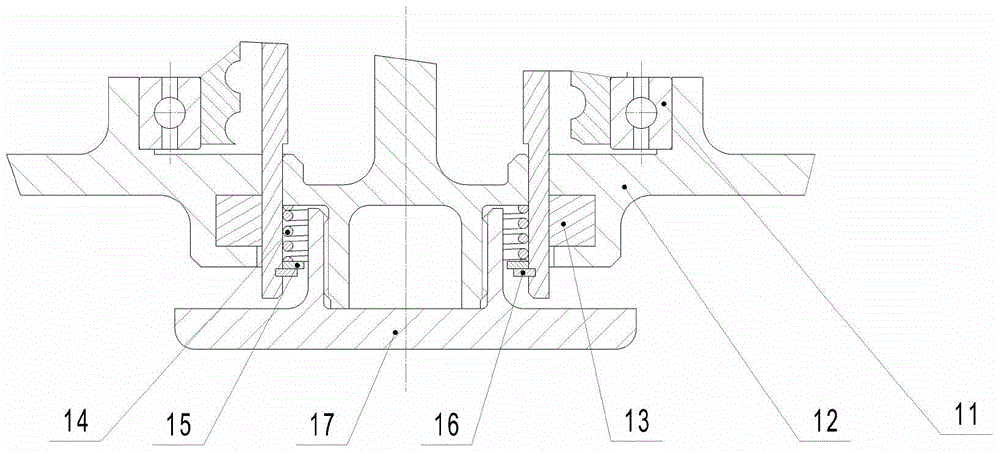

[0026] This example is an electric brake actuator integrated with a force sensor and a ball screw, including a housing, a ball screw assembly, a needle bearing 7, a force sensor assembly 6, a data line 4, a push rod 8, and a thrust needle roller Bearing 10, deep groove ball bearing 11, preload spring 14, spring pad 15, collar 16, dynamic sealing ring 13 and heat insulation pad 17.

[0027] The housing includes a middle housing 9, a lower housing 12 and a housing upper cover 1, and the ball screw assembly is located in the housing. The ball screw assembly includes a lead screw 3 , a nut 2 and a ball 5 . The upper part of the outer peripheral surface of the nut 2 in the ball screw assembly cooperates with the inner surface of the middle housing through the needle bearing 7; The inner surface of the upper hole wall at the maximum aperture is matched; the outer circumferential surface at the lower end of the nut 2 is matched with the inner surface of the lower housing 12 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com