Tension balancing and auto-adjusting device for winding ropes

An automatic adjustment and steel wire rope technology, which is applied in the direction of transportation and packaging, lifting equipment in mines, etc., can solve the problems of increased bending stress of steel wire ropes, aggravated bending fatigue, and reduced effective lifting load, so as to reduce weight and adjust response Fast, reduce the effect of left and right polarization swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

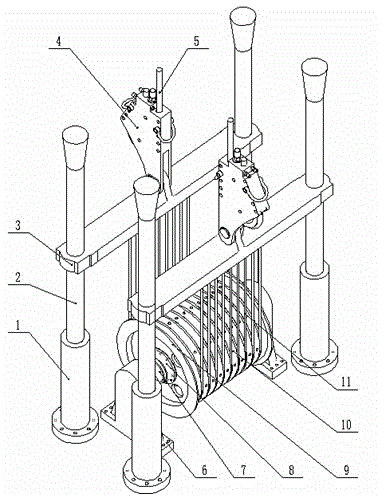

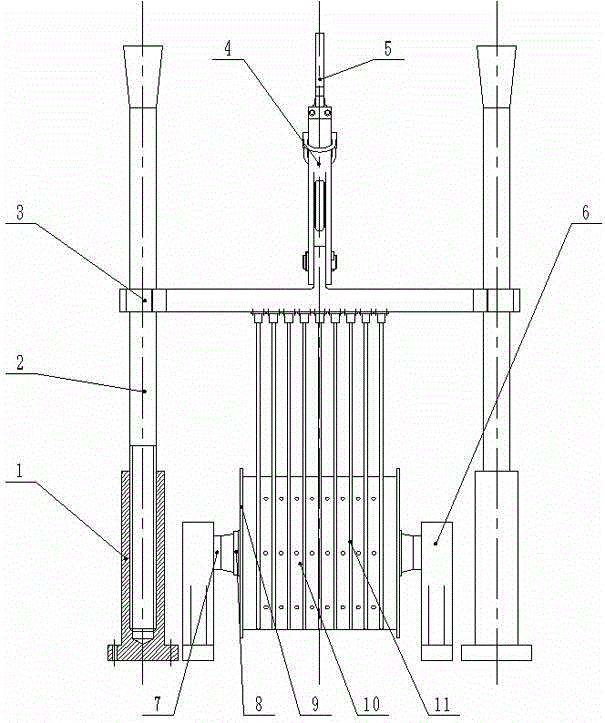

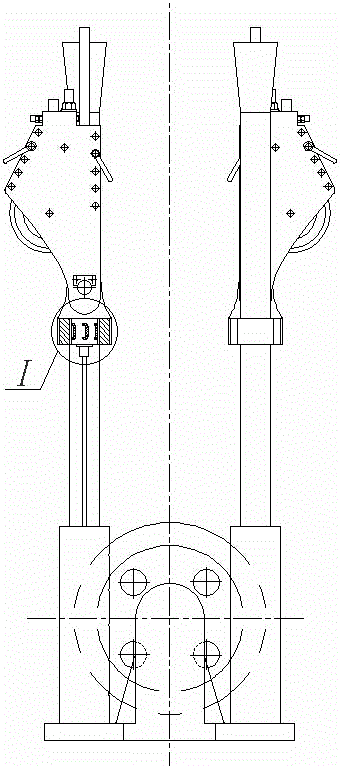

[0031] The hoisting wire rope tension balance automatic adjustment device in this specific embodiment has a structure such as Figure 1-6 As shown, an automatic adjustment device for lifting steel wire rope tension balance includes two lifting steel wire ropes 5, which also includes a roller device that is installed horizontally and fixed on the lifting container by bearings and bearing seats 6 at both ends. The surface has a number of rope grooves arranged in the circumferential direction and evenly arranged in the axial direction. Each rope groove is correspondingly provided with a steel wire rope 11 for balancing. The lower surface of a load-bearing beam 3 arranged horizontally, and the upper surfaces of two load-bearing beams 3 are connected to the respective corresponding lifting wire ropes 5 .

[0032] In this way, the adjustment is realized by arrangi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com