Novel combined type hydrogen chloride synthetic furnace with byproduct of high-pressure steam

A technology of high-pressure steam and synthesis furnace, which is applied in the direction of chlorine/hydrogen chloride and hydrogen chloride preparation, etc. It can solve the problems of poor sealing effect, low heat energy utilization rate, corrosion of the steel shell of the outer cylinder of the furnace, etc., so as to prolong the service life, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

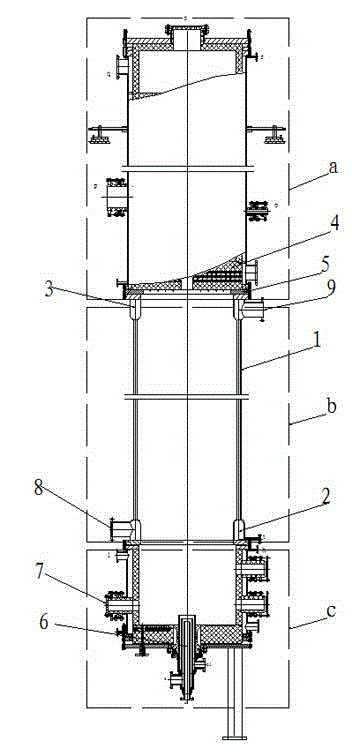

[0017] like figure 1 and figure 2 As shown, the invention discloses a novel combined hydrogen chloride synthesis furnace for high-pressure steam by-product, including a synthesis furnace and a cooler at the top thereof;

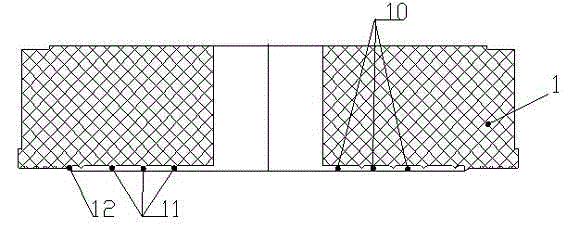

[0018] The synthesis furnace is divided into an upper section a, a middle section b, and a lower section c. Both the upper section a and the lower section c are composed of a graphite cylinder and a steel shell set outside the cylinder, and the middle section b is a steel shell. The steel shell consists of several The steel condensing pipe 1 in the vertical direction is made of ring-shaped sealing fit. The lower end of the steel condensing pipe 1 extends downward into the annular cavity A of a closed annular steel sleeve A2, and is sealed with the annular steel sleeve A2. Supported by the annular steel sleeve A2 on the upper end surface of the lower section c of the synthesis furnace, the upper end of the steel condensation pipe 1 extends upward into the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com