A kind of anti-corrosion composite enamel coating and preparation method thereof

An enamel and coating technology, which is applied in the composite enamel coating of superalloy parts and its preparation field, can solve the problems of poor diffusion and infiltration ability of hot corrosion medium, high content of low melting point components, etc., and achieve excellent protection and production The effect of high efficiency and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The composite enamel coating is prepared with high-temperature alloy K444 as the substrate, and the preparation process is as follows:

[0030] (1) Smelting of enamel and glaze:

[0031] The composition ratio of the enamel matrix is: 58wt% silica, 13wt% zirconium dioxide, 6wt% aluminum oxide, 5wt% calcium oxide, 4wt% boron trioxide, 3wt% strontium oxide, 3wt% titanium dioxide, sodium oxide 2wt%, potassium oxide 4wt%, nickel oxide 2wt%.

[0032] Mix the above oxides by ball milling at a speed of 320 rpm for 24 hours. After mixing evenly, heat and smelt. The smelting process is as follows:

[0033] RT→500℃, heating at uniform speed for 1 hour;

[0034] 500℃→1000℃, heating at an average speed for 40 minutes;

[0035] 1000℃→1725℃, heating at uniform speed for 1 hour;

[0036] Constant temperature at 1725°C for 1.5 hours and then water quenching to obtain enamel glaze of specific composition.

[0037] (2) Preparation of enamel powder: the enamel glaze obtained after water quenching is s...

Embodiment 2

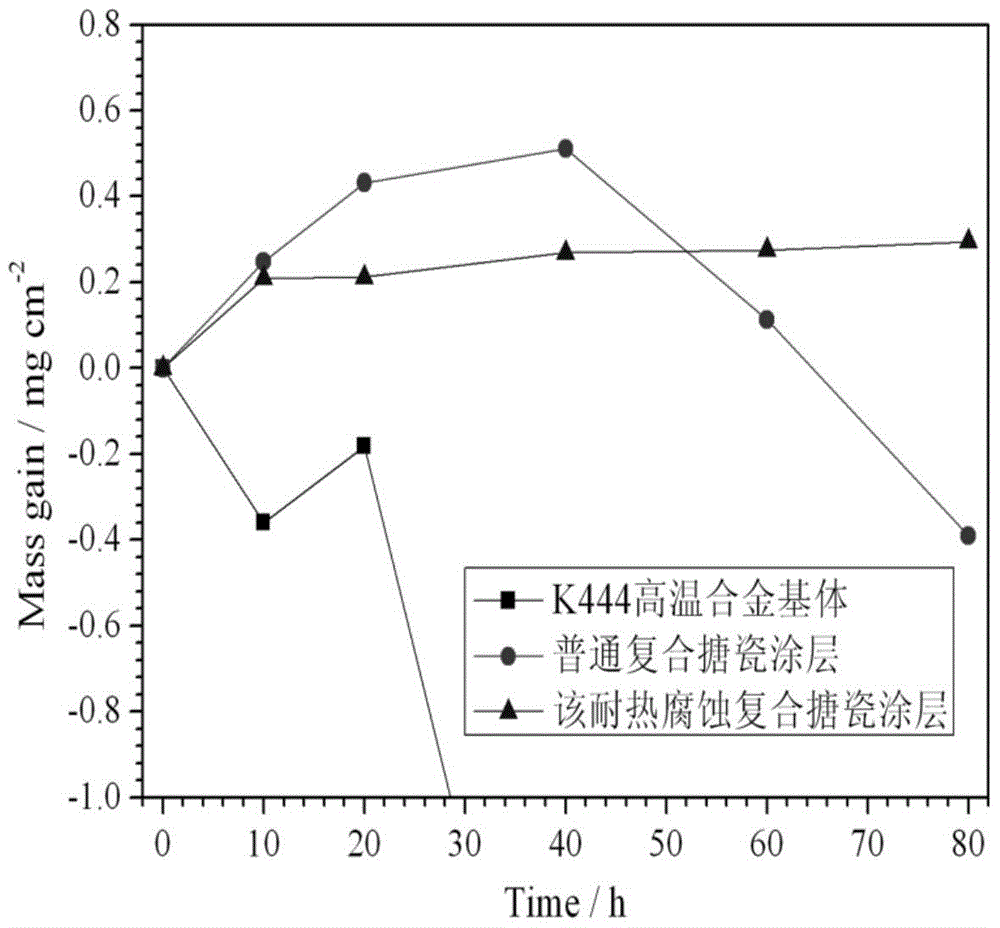

[0043] The preparation process of the heat-resistant corrosion-resistant composite enamel coating is the same as that of Example 1. The alloy matrix is K444 high temperature alloy. Using the same process, a common composite enamel coating was prepared by sintering on the K444 superalloy substrate. Three sets of samples (K444 high-temperature alloy substrate, ordinary composite enamel coating and the heat-resistant corrosion composite enamel coating) were thermally corroded at 900°C for 80 hours. The detailed process of hot corrosion is as follows:

[0044] (1) Hot corrosion salt: saturated 75wt% Na 2 SO 4 +25wt% NaCl brine;

[0045] (2) Through the air compressor, the 0.2MPa pressure is sprayed and deposited on the K444 superalloy substrate at a time of 2.0~3.0mg / cm -2 Compound salt (75wt%Na 2 SO 4 +25wt%NaCl);

[0046] (3) Put the three groups of samples deposited with solid salt film into a constant temperature muffle furnace, and etch them at 900°C for 5h, 20h, 40h, 60h, and ...

Embodiment 3

[0053] The difference from Example 1 is that the composition of the enamel matrix is as follows:

[0054] Silica 62wt%, zirconium dioxide 10.5wt%, aluminum oxide 7wt%, calcium oxide 6wt%, boron trioxide 5wt%, strontium oxide 3.5wt%, titanium dioxide 3wt%, potassium oxide 2wt%, nickel oxide 1wt %.

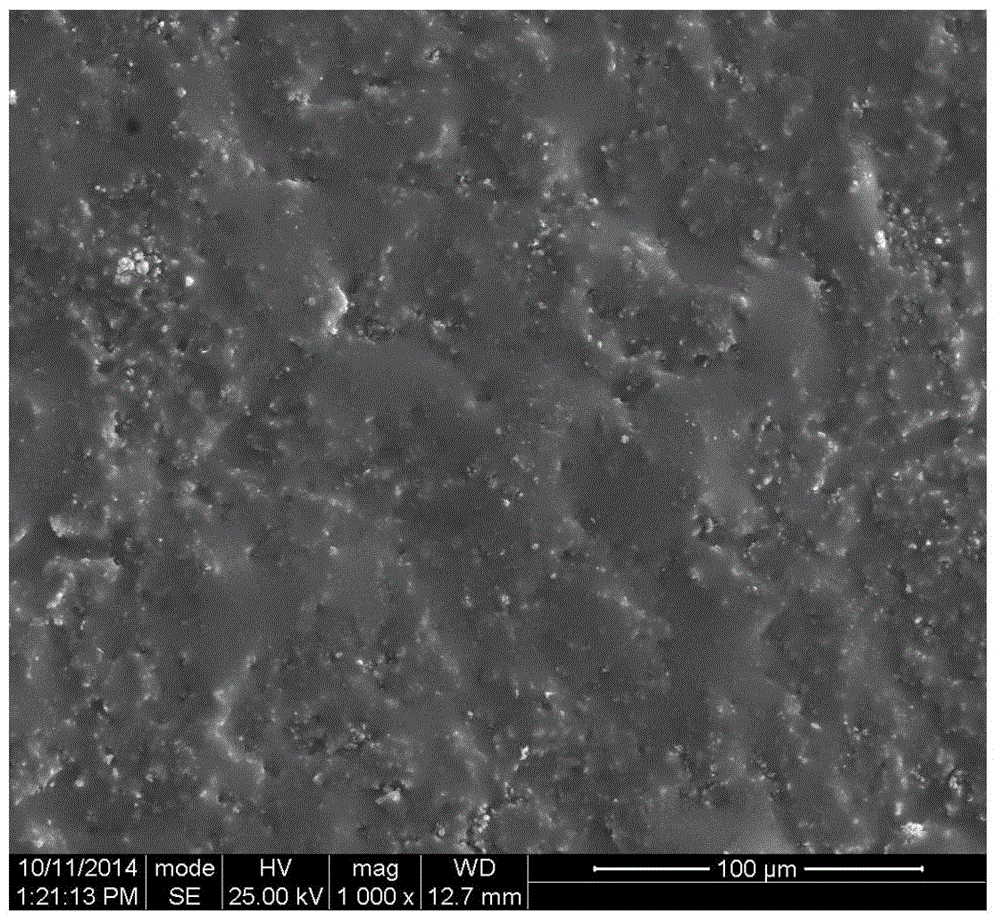

[0055] The heat-resistant corrosion-resistant enamel coating prepared on K444 superalloy has a compact structure and no bubbles, cracks and other microscopic defects, such as Figure 7 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com