Biodegradable polyester, preparation process thereof and products comprising said polyester

A biodegradable polyester and biodegradable technology, applied in the field of biodegradable polyester, its preparation and products containing the polyester, can solve the problems of difficult separation of polyethylene, difficult recycling or treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

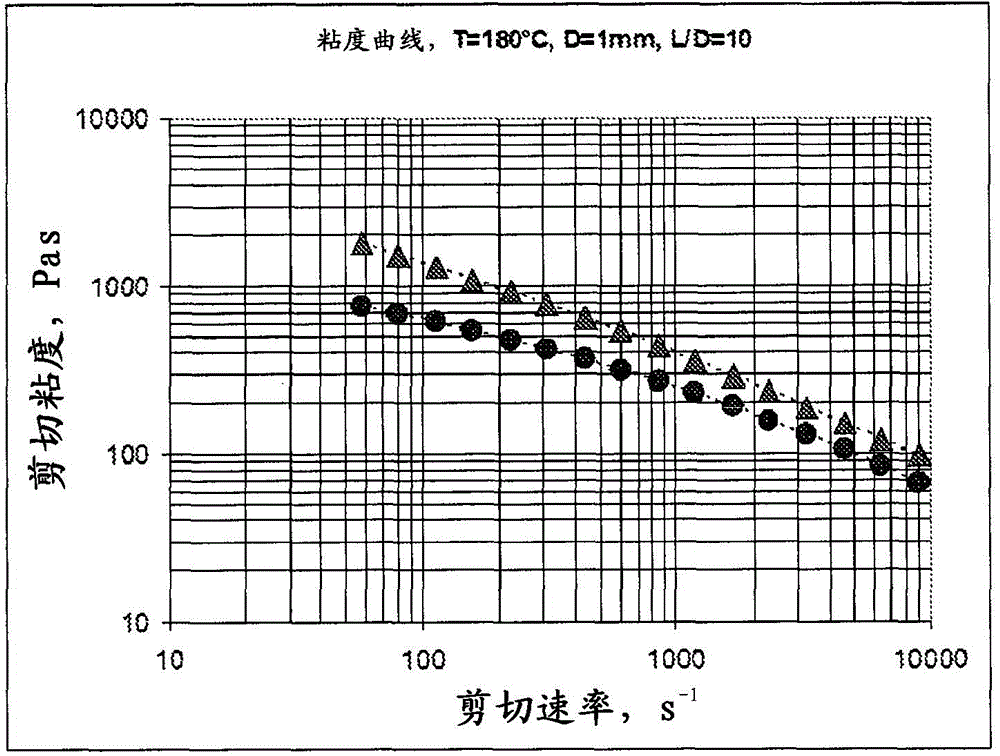

[0107] Synthesis of polybutylene sebacate-co-butylene terephthalate (PBST), its terephthalic acid content = 56mol%, MFI = 10 (190 ° C and 2.16 kg), 180 ° C and γ = 103.7s -1 Lower shear viscosity = 620 Pas, and terminal unsaturated group content = 0.48 mol%.

[0108] Regarding the measurement of the unsaturated group content, the measurement was carried out by H1 NMR 300 MHz with a pulse-acquisition sequence characterized by a 30° pulse phase, spectral range = 4 kHz, 5 sec delay and 6000 scans. The measuring frequency range is 4.9~6.2ppm. The sample to be analyzed was obtained by preparing a solution of the polymer at a concentration of 65 mg / ml in deuterated chloroform. 270 kg of this PBST in granular form were fed together with 40 g of α,α'-bis(tert-butylperoxy)diisopropylbenzene (LuperoxF) (corresponding to 0.0148 wt % relative to PBST) under the following conditions In the twin-screw extruder:

[0109] -Extruder temperature characteristics: 30-100-200-170-150×3-160℃

...

Embodiment 2

[0125] Synthesis of polybutylene sebacate-co-butylene terephthalate (PBST) with terephthalic acid content = 56 mol%, MFI = 11.1 (190 °C and 2.16 kg), shear at 180 °C Viscosity = 580 Pas, and terminal unsaturated group content = 0.42 mol%.

[0126] 280 kg of this PBST in the form of granules was fed together with 67 g of α,α'-bis(tert-butylperoxy)diisopropylbenzene (LuperoxF) (corresponding to 0.0239 wt % relative to PBST) under the following conditions In the twin-screw extruder:

[0127] -Extruder temperature characteristics: 30-100-200×3-180-155-165℃

[0128] - Twin-screw rotation speed: 200rpm

[0129] -Head pressure: 93kg / cm 2

[0130] - Active degassing.

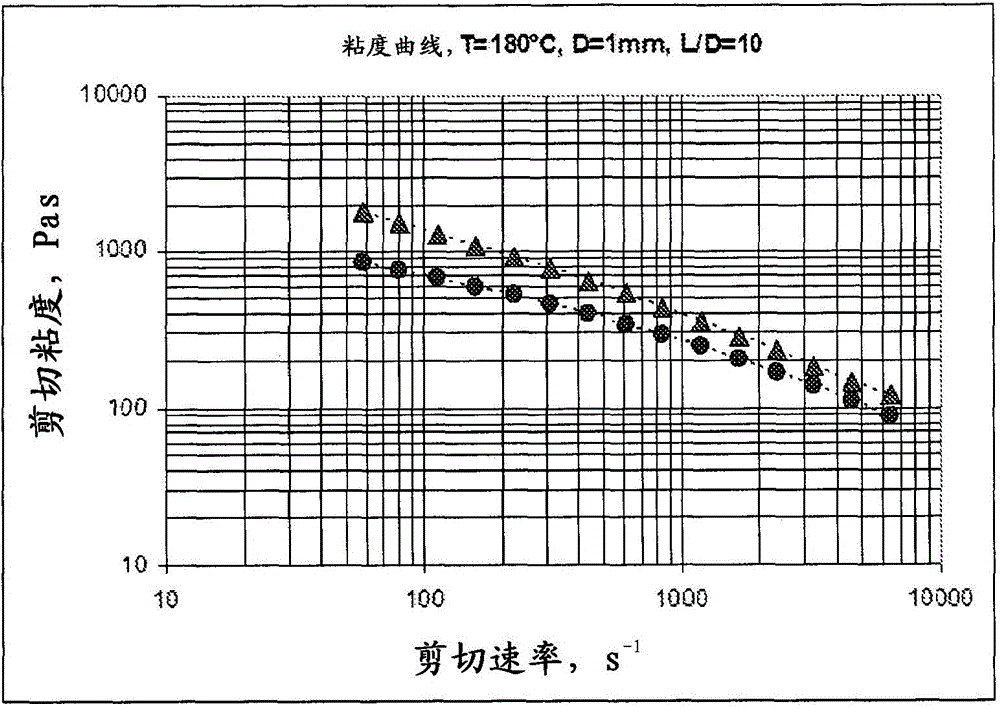

[0131] The shear viscosity of the obtained product at 180°C=1170Pas, thermal stability constant=0.3×10 -4 , Melt strength at 180°C = 2.6g, and elongation at break at 180°C > 50. The product thus obtained in granular form was subsequently fed into the same extrusion coating system as in Example 1.

Embodiment 3

[0133] Synthesis of polybutylene sebacate-co-butylene terephthalate (PBST) with terephthalic acid content = 56 mol%, MFI = 10.6 (190 °C and 2.16 kg), shear at 180 °C Viscosity = 590 Pas, and terminal unsaturated group content = 0.51 mol%.

[0134] 280 kg of this PBST in the form of granules was fed together with 45 g of α, α'-bis(tert-butylperoxy) diisopropylbenzene (LuperoxF) (corresponding to 0.016 wt % with respect to PBST) into a bismuth under the following conditions In the screw extruder:

[0135] -Extruder temperature characteristics: 30-100-200×3-180-155-165℃

[0136] - Twin-screw rotation speed: 210rpm

[0137] -Head pressure: 94kg / cm 2

[0138] - Active degassing.

[0139] The shear viscosity of the obtained product at 180°C=1200Pas, thermal stability constant=0.2×10 -4 , Melt strength at 180°C = 2.9g, and elongation at break at 180°C > 50.

[0140] The product thus obtained in granular form was subsequently fed into the same extrusion coating system as in Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap