A kind of high rigidity TPV toughened polypropylene composition and preparation method thereof

A polypropylene composition, high rigidity technology, applied in the field of polyolefin thermoplastic elastomer toughened modified polypropylene resin composition, dynamic vulcanization to prepare the above resin composition, can solve the problem that the rigidity of TPV toughened PP is not given, etc. , to achieve good industrialization prospects, slow speed, and ensure the effect of comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

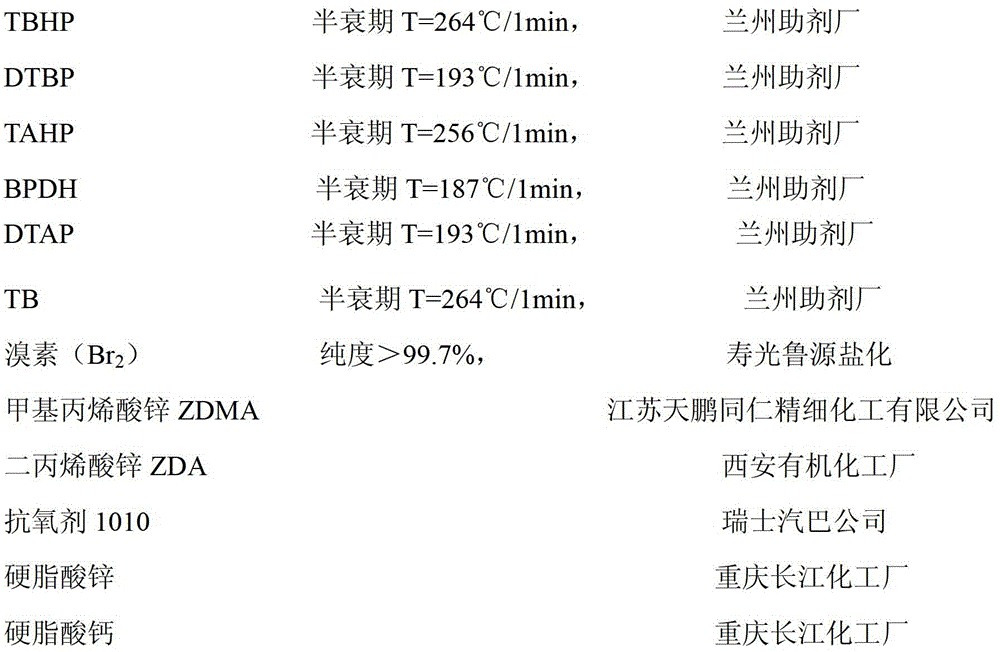

[0040] Preparation of polypropylene composition: first put 0.003kg DTBP and 0.013kg TBHP and 0.03kg acetone solvent into a beaker and mix for 3 minutes, then mix the organic peroxide solution and 0.20kg of TPV, 0.01kg of bromine (Br 2 ) (S), 0.01kg ZDMA together in a high-speed mixer and mixed at high speed for 5 minutes to make a premixed masterbatch; then polypropylene F4012kg and premixed masterbatch, antioxidant 10100.004kg, zinc stearate 0.008kg, Mix at high speed in a high-speed mixer for 7 minutes; put the mixed material into a Ф34 twin-screw extruder, and the reaction temperature (°C) of each section of the screw is: 185, 190, 200, 205, 210, 220, 210, 200 , 190; After carrying out the extrusion reaction for 4 minutes, extrude, cool, and granulate to obtain a polypropylene composition. The prepared composition pellets were made into standard samples by injection method for testing, and their properties are shown in Table 1.

Embodiment 2

[0042] Preparation of polypropylene composition: first put 0.0026kg BPDH and 0.0154kg TB and 0.04kg acetone solvent into a beaker and mix for 3 minutes, then mix the organic peroxide solution and 0.28kg of TPV, 0.012kg of bromine (Br 2 ), 0.013kg ZDMA together in a high-speed mixer for 6min at high speed to make a premixed masterbatch; then 2kg of polypropylene F401, premixed masterbatch, 10100.005kg of antioxidant, and 0.008kg of zinc stearate were mixed at high speed Mix at high speed in the mixer for 8 minutes; put the mixed material into the Ф34 twin-screw extruder, the reaction temperature (°C) of each section of the screw is: 185, 190, 200, 205, 210, 220, 210, 200, 190 ; After carrying out the extrusion reaction for 5 minutes, extrude, cool, and granulate to obtain a polypropylene composition. The prepared composition pellets were made into standard samples by injection method for testing, and their properties are shown in Table 1.

Embodiment 3

[0044] Preparation of polypropylene composition: first put 0.0024kg DTBP and 0.0166kg TBHP and 0.05kg acetone solvent into a beaker and mix for 3 minutes, then mix the organic peroxide solution and 0.32kg of TPV, 0.013kg of bromine (Br 2 ), 0.015kg ZDMA together in a high-speed mixer and mixed at high speed for 7 minutes to make a premixed masterbatch; then polypropylene F401 2kg and premixed masterbatch, antioxidant 1010 0.005kg, zinc stearate 0.009kg, in Mix at high speed in a high-speed mixer for 9 minutes; add the mixed materials into the Ф34 twin-screw extruder, and the reaction temperature (°C) of each section of the screw is: 185, 190, 200, 205, 210, 220, 210, 200, 190; after carrying out the extrusion reaction for 6 minutes, extrude, cool, and granulate to obtain a polypropylene composition. The prepared composition pellets were made into standard samples by injection method for testing, and their properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com