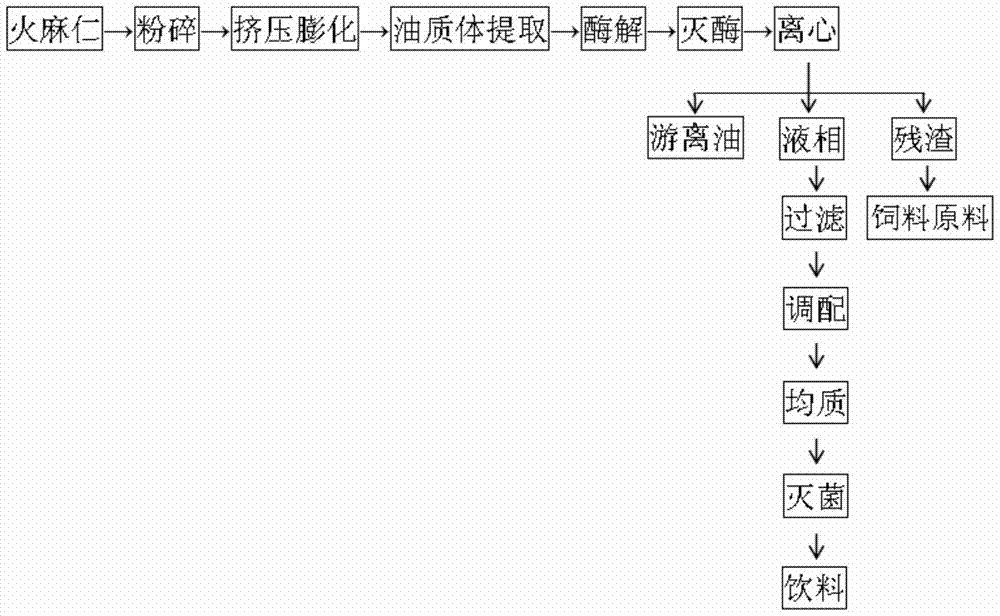

A method for extracting oil from hemp seeds by water enzymatic method and a hemp seed protein drink

A protein drink, hemp seed technology, applied in the production of fat/fat, fat production, food science, etc., can solve the problems of insufficient liquid phase utilization, low yield of clear oil, serious emulsification, etc., and reduce the burden of demulsification process. , The quality of crude oil is good, and the effect of reducing economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Weigh 2kg of shelled hemp seeds, coarsely pulverize and extrude and expand, the die aperture is 8mm, the rotating speed of the extruder is 90rpm, the rotating speed of the feeder is 200rpm, the casing temperature is 60°C, and the moisture content of the material after extrusion is 9.6%;

[0051] Take the extruded and puffed hemp seeds, coarsely pulverize them with a pulverizer, and then grind them with a mill until the particle size is ≤50 μm, weigh 1kg, add 4L of deionized water, stir evenly, adjust the pH of the system to 8.5, and the temperature is 60 ℃, extract for 35min;

[0052] Regulate system pH to 8.5 then, add alkaline protease Alcalase 2.4L (add-on is the 2% of the hemp seed weight after extrusion puffing), after acting for 4 hours, add neutral protease Alphalase (add-on is after extrusion puffing 0.5% of the weight of the hemp seed), stirred and enzymolyzed for 3h to obtain the enzymolyzate;

[0053] Raise the temperature of the obtained enzymolysis solutio...

Embodiment 2

[0056] Weigh 3kg of shelled hemp seeds, carry out extrusion and puffing after coarse crushing, the die aperture is 6mm, the speed of the extruder is 70rpm, the speed of the feeder is 175rpm, the casing temperature is 55°C, and the water content of the material after extrusion is 6.2%;

[0057] Take the extruded and puffed hemp seeds, coarsely pulverize them with a grinder, and then grind them with a mill until the particle size is ≤50 μm, weigh 500 g, add 1.5 L of deionized water, stir evenly, adjust the pH of the system to 8.0, and the temperature is 60°C, extract for 30min;

[0058] Adjust the pH of the system to 8.5, add Alcalase 2.4L with 1% weight of extruded and expanded hemp seeds and neutral protease Alphalase with 1% weight of extruded and expanded hemp seeds, and stir slowly for 6 hours;

[0059] Raise the temperature of the system to 95°C and maintain it for 5 minutes to inactivate the enzyme, centrifuge at 4500 rpm for 15 minutes, and the enzymolysis liquid is divi...

Embodiment 3

[0062] Take by weighing 5kg shelled hemp seeds, carry out extrusion puffing after coarse pulverization, die aperture 6mm, extruder rotating speed 80rpm, feeder rotating speed 188rpm, casing temperature is 70 ℃, and the material moisture content after extrusion puffing is 7.8%;

[0063] Take the extruded and expanded hemp seeds, coarsely pulverize them with a pulverizer, and then grind them with a mill until the particle size is ≤50 μm, weigh 1.5kg, add 7.5L deionized water, and adjust the pH of the system to 8.0 after stirring evenly. at 60°C, extract for 30 minutes;

[0064] Adjust the pH of the system to 9.0, add 1.5% of the weight of the hemp seed Alcalase 2.4L and 1% of the neutral protease Alphalase, and stir slowly for 5 hours;

[0065] The temperature of the system was raised to 95°C and kept for 5 minutes to inactivate the enzyme, centrifuged at 4500 rpm for 15 minutes, and the enzymolysis liquid was divided into three layers: clear oil, liquid phase and residue; the y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com